Linearl laser detector of plate shape

A detection device, a linear technology, applied in the direction of length measuring device, metal processing equipment, metal rolling, etc., can solve problems such as hindering the reliability of the measuring system, and achieve the effects of simple structure, low cost, and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

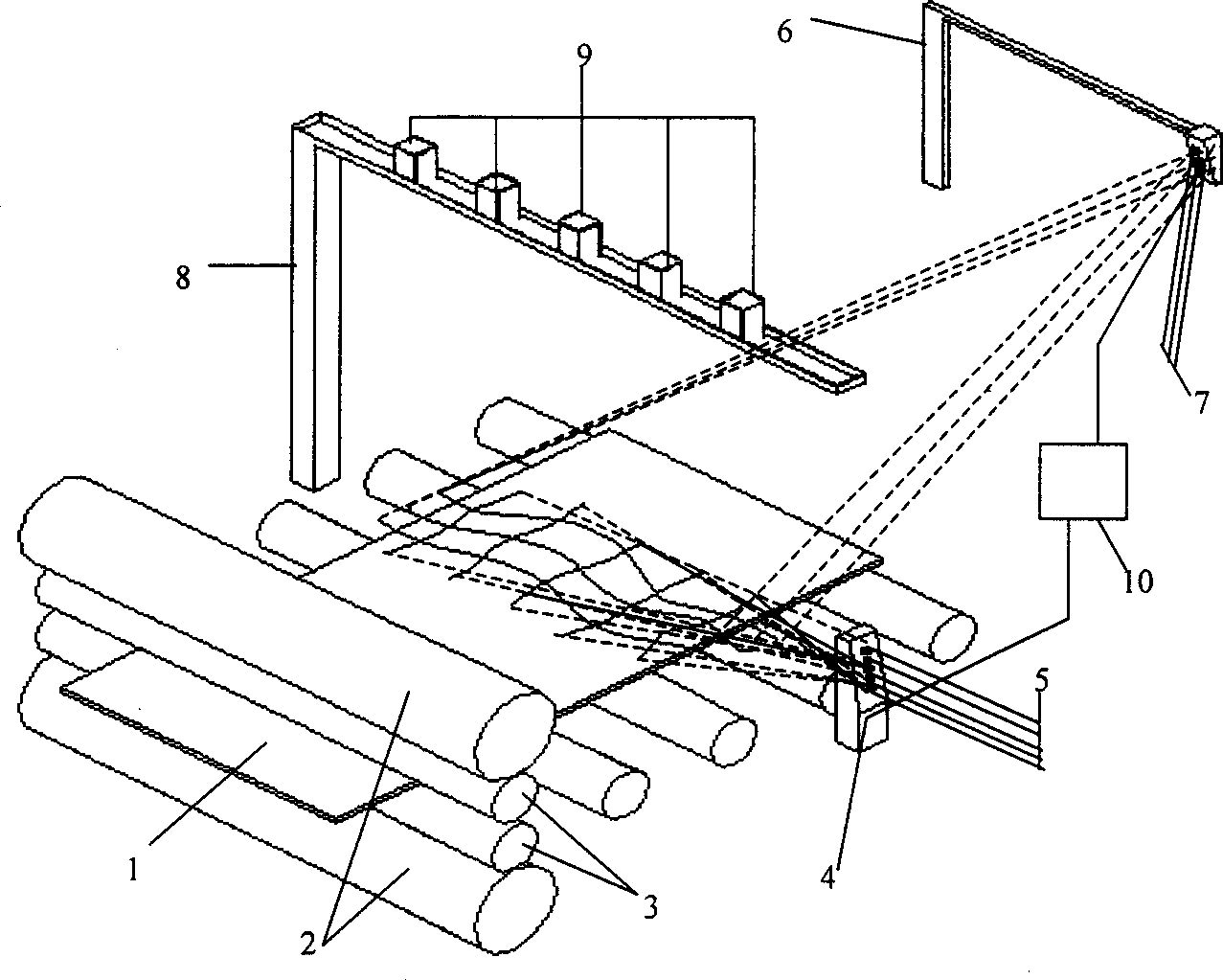

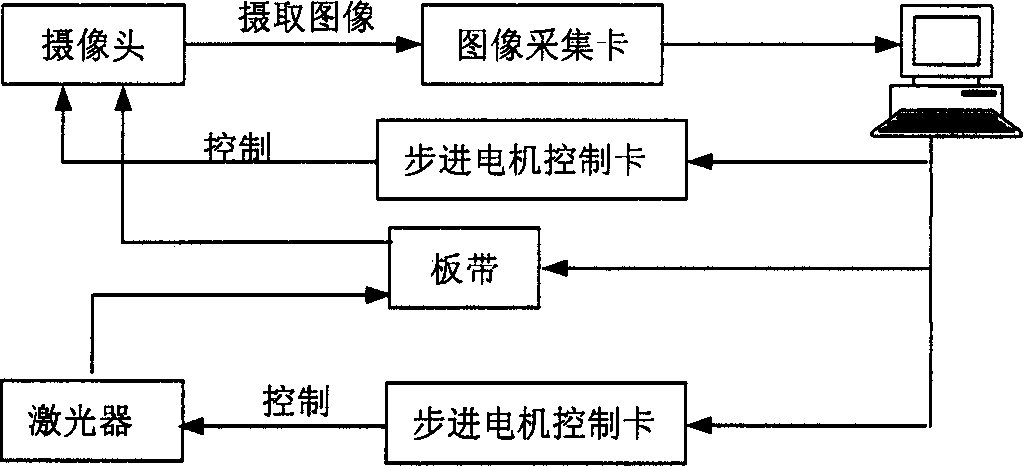

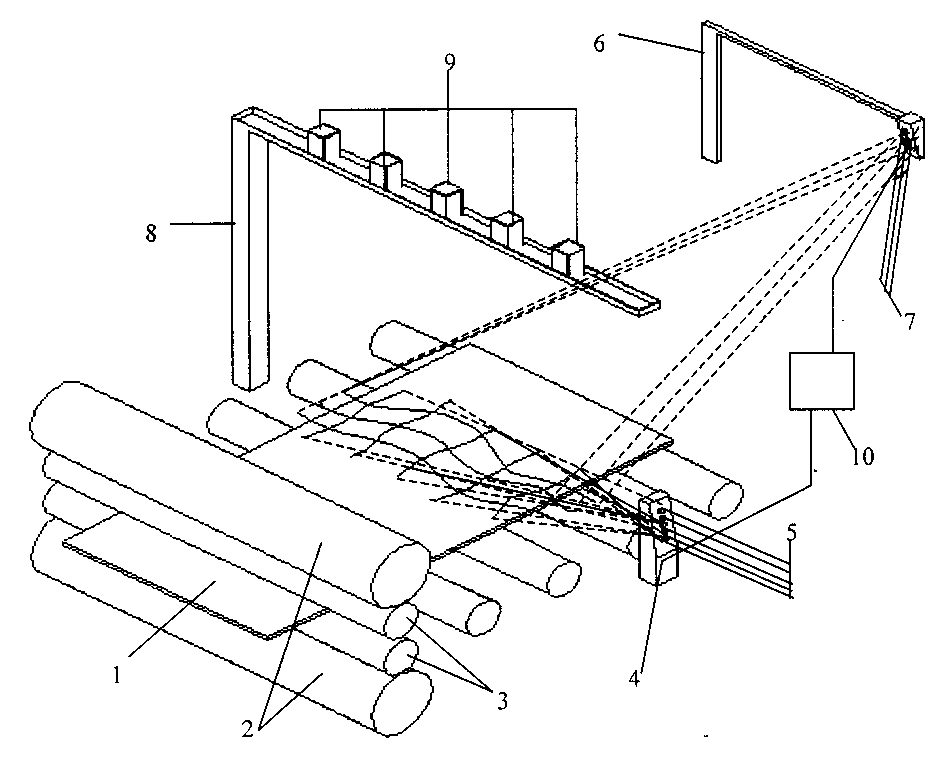

Embodiment 1

[0015] Embodiment 1. by strip steel (1), back-up roll (2), work roll (3), horizontal laser support frame and laser position angle control mechanism (4), 3 horizontal linear semiconductor laser generators (5), Vertical laser support frame and laser position angle control mechanism (6), 3 vertical linear semiconductor laser generators (7), camera support frame and position control mechanism (8), 5 area array CCD cameras and optical filters (9 ), a computer processing system (10), a linear laser plate shape measuring device, the distance between the laser beams is irradiated at an equal distance, the distance is 100mm, and the inclination angle of the laser beams is 35°.

Embodiment 2

[0016] Embodiment 2. By strip steel (1), back-up roll (2), work roll (3), horizontal laser support frame and laser position angle control mechanism (4), 5 horizontal linear semiconductor laser generators (5), Vertical laser support frame and laser position angle control mechanism (6), 5 vertical linear semiconductor laser generators (7), camera support frame and position control mechanism (8), 5 area array CCD cameras and optical filters (9 ), a computer processing system (10), a linear laser plate shape measuring device, the distance between the laser beams is irradiated at an equidistant distance, the distance is 50mm, and the inclination angle of the laser beams is 45°.

Embodiment 3

[0017] Embodiment 3. By strip steel (1), back-up roll (2), work roll (3), horizontal laser support frame and laser position angle control mechanism (4), 7 horizontal linear semiconductor laser generators (5), Vertical laser support frame and laser position angle control mechanism (6), 7 vertical linear semiconductor laser generators (7), camera support frame and position control mechanism (8), 8 area array CCD cameras and optical filters (9 ), a computer processing system (10), a linear laser plate shape measuring device, the distance between the laser beams is irradiated at an equal distance, the distance is 30mm, and the inclination angle of the laser beams is 40°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com