Rolling bearing unit with sensor

a technology of rolling bearing and sensor, which is applied in the direction of solid vibration measurement, metal rolling stand, calender, etc., can solve the problems of troublesome operation to replace the rolling roller, data can be recorded wrong, and labor and time, so as to facilitate further replacement, facilitate the replacement of the member, and enhance the accuracy of temperature and vibration detection of the rolling bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

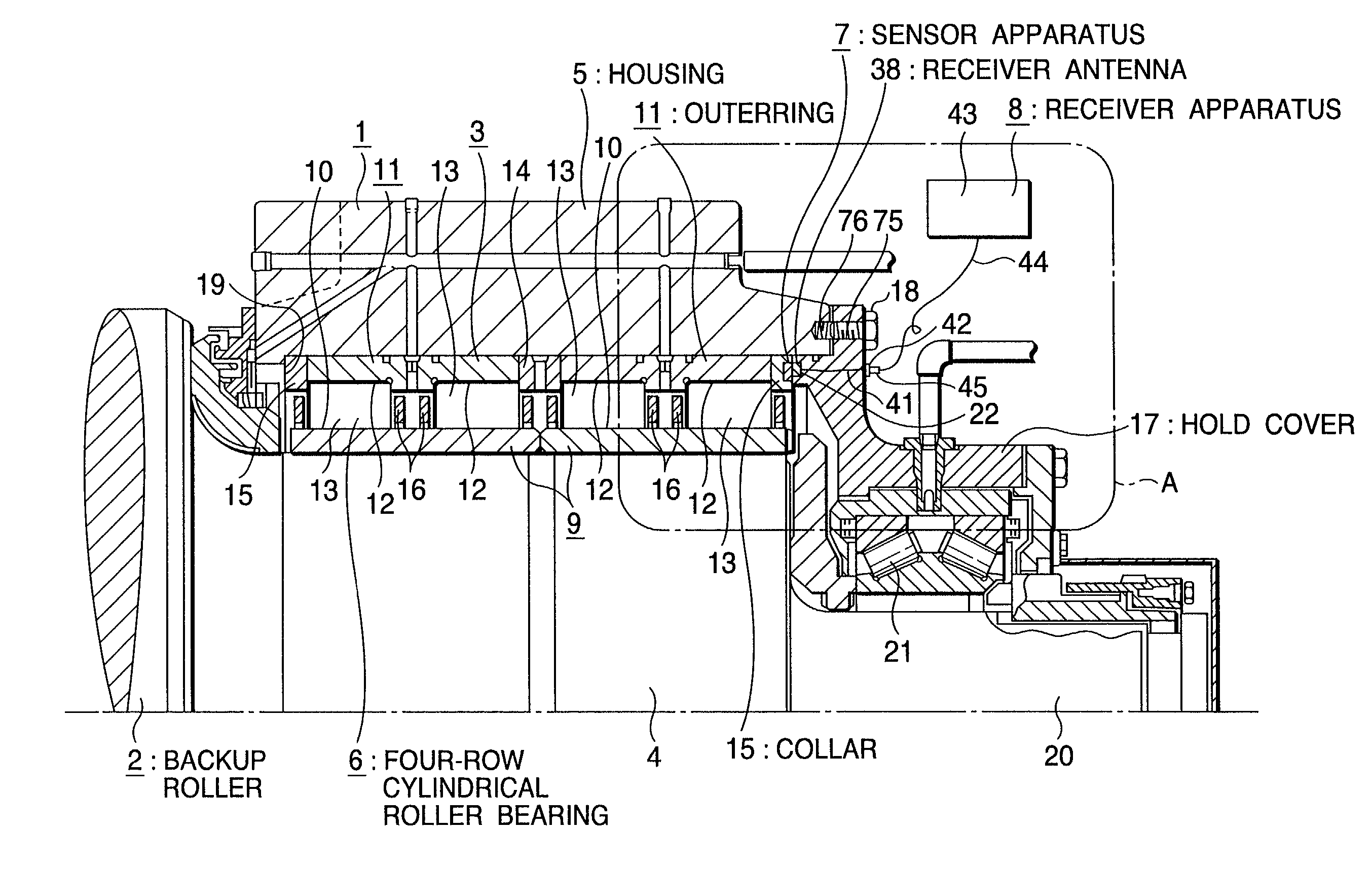

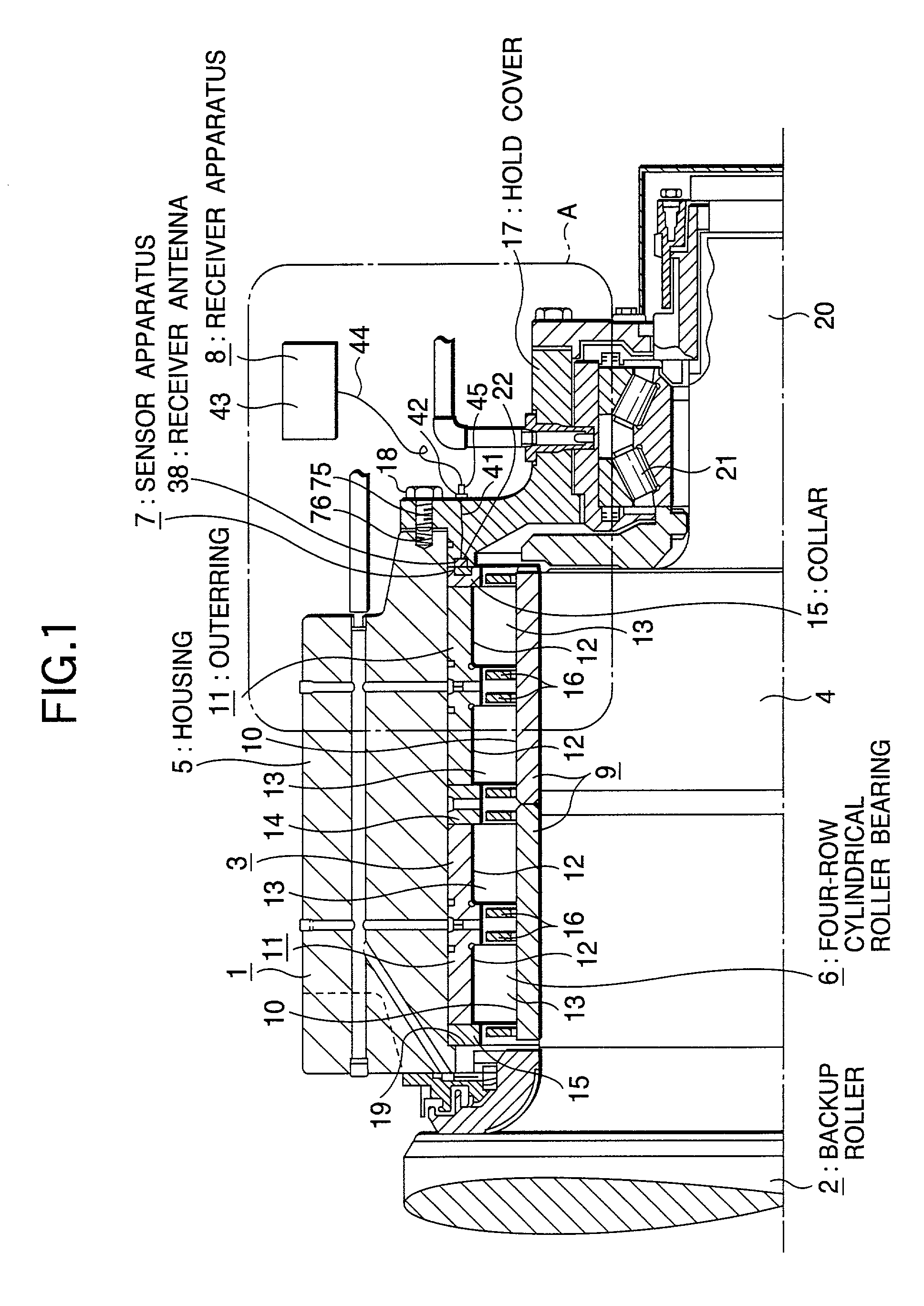

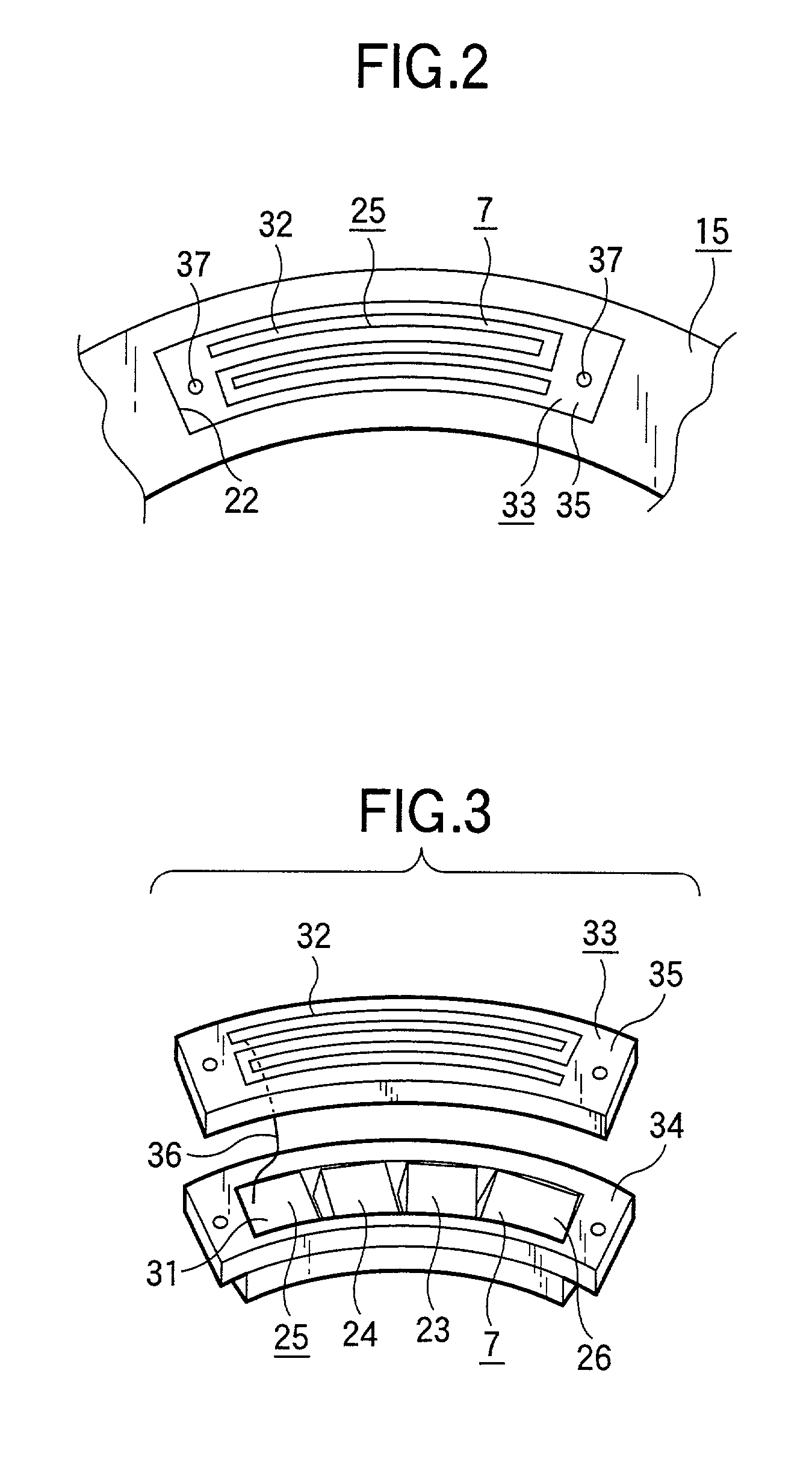

[0036] FIGS. 1 to 5 show a rolling bearing unit with a sensor according to the invention, corresponding to a second aspect of the invention. In this embodiment, a rolling bearing unit with a sensor is incorporated into rotation support portions formed in the axial-direction two end portions of a backup roller 2 disposed in a rolling mill 1 which is used to roll metal material such as iron and steel. That is, a roller neck 4, which is disposed in the central portion between the axial-direction two end faces of the backup roller 2, is rotatably supported inside a housing 4, which does not rotate even when it is in use, by a four-row cylindrical roller bearing 6. And, the four-row cylindrical roller bearing 6, a sensor unit 7 and a receiver apparatus 8 cooperate together in constituting the present bearing unit 3 with a sensor. Of these three elements, the four-row cylindrical roller bearing 6 comprises a plurality of cylindrical rollers 13, 13 respectively between inner raceways 10, 1...

second embodiment

[0045] Next, FIG. 7 shows a rolling bearing unit with a sensor according to the invention, also corresponding to a second aspect of the invention. In the present embodiment, in the diameter-direction middle portion of the axial-direction inner surface (in FIG. 7, the front side surface) of the hold cover 17, there is disposed a substantially-circular-ring-shaped receiver antenna 38a in such a manner that it is concentric with the hold cover 17. And, a portion of the receiver antenna 38a in the circumferential direction thereof is disposed opposed to the sensor unit 7 (see FIGS. 1 and 2) which is disposed on the above-mentioned one collar 15. In the thus structured present embodiment, when it is in use, even in case the above-mentioned one collar 15 is rotated with respect to the hold cover 17, the sensor unit 7 disposed on the above one collar 15 can be disposed opposed to a portion of the receive antenna 38a, so that radio signals transmitted from the sensor unit 7 can be received ...

third embodiment

[0047] Next, FIG. 8 shows a rolling bearing unit with a sensor according to the invention, also corresponding to the second aspect of the invention. In the case of a rolling bearing unit 3 with a sensor according to the present embodiment, the roller neck 47 of a work roller 46 is supported so as to be rotatable with respect to a housing 48. Also, the present rolling bearing unit with a sensor 3 includes a four-row conical roller bearing 49. This four-row conical roller bearing 49 comprises a plurality of cylindrical rollers 54, 54 interposed between inner raceways 51, 51 formed in the outer peripheral surfaces of a pair of inner rings 50, 50 fitted with and fixed to the outer surface of the roller neck 47 of the work roller 46 and a plurality of outer raceways 53, 53 formed in the inner peripheral surfaces of a pair of three outer rings 52a, 52b fitted with and fixed to the inner surface of the housing 5. Also, not only a hold cover 17 is fixed to the axial-direction outer end port...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com