Band steel deflection and floating quantity laser scanning detection method and deflection correction system

The technology of strip deviation and laser scanning is applied in the field of scanning detection method and deviation correction system, which can solve the problems of long-term reliable operation, expensive equipment and high cost, and achieves improved automatic detection level, convenient equipment installation and maintenance, and detection accuracy. controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

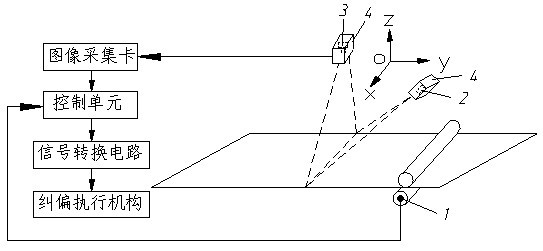

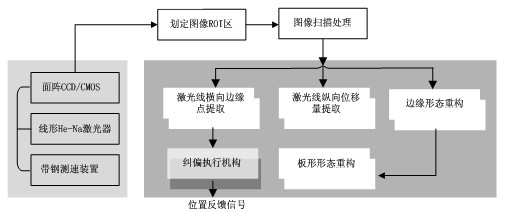

[0028] The laser scanning detection method for steel strip deviation and floating amount of the present invention, the detection steps are:

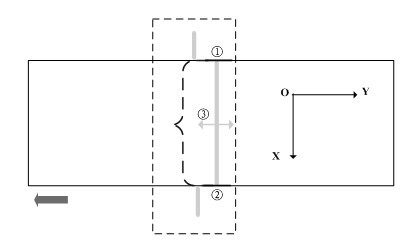

[0029] 1) Use a linear (line width 1mm) laser emitter (inclined at a certain angle) to irradiate the strip steel, forming a high-brightness laser linear beam perpendicular to the length direction (ie running direction or longitudinal direction) in the width direction (ie, transverse direction) of the strip steel , the laser linear beam fully covers the width of the strip and is greater than the width of the strip;

[0030] 2) An area array image sensor is set above the strip steel, and the laser linear beam is scanned by the area array image sensor in real time. The scanning direction of the area array image sensor is perpendicular to the surface of the strip steel (that is, the imaging target surface is parallel to the surface of the strip steel, so the calculation is simple and more efficient. facilitate subsequent calculation and data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com