Computer vision detection method for weld contour features based on discrete sequence points

A computer vision, discrete sequence technology, applied in measurement devices, instruments, and optical devices, etc., can solve problems such as being susceptible to noise, misdetecting straight lines, and not considering overall information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

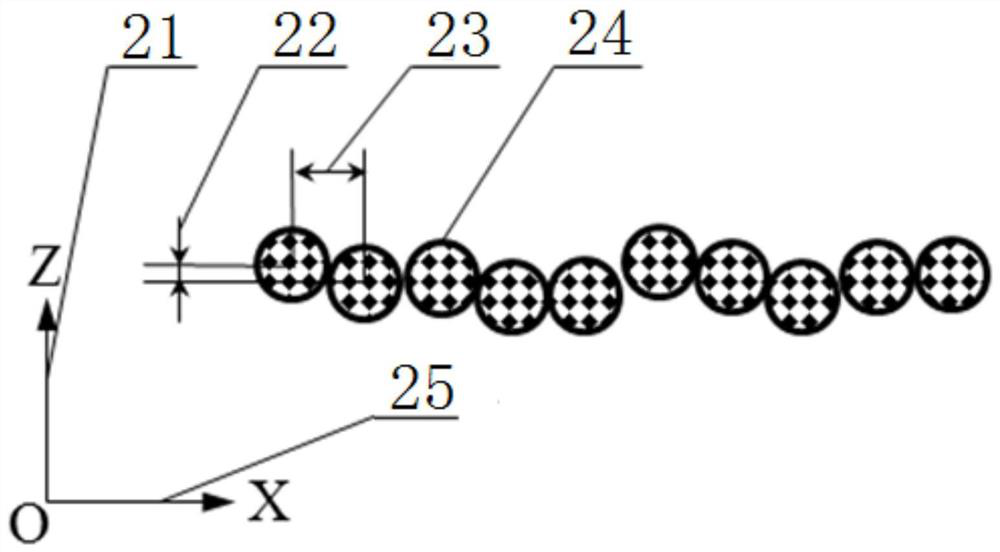

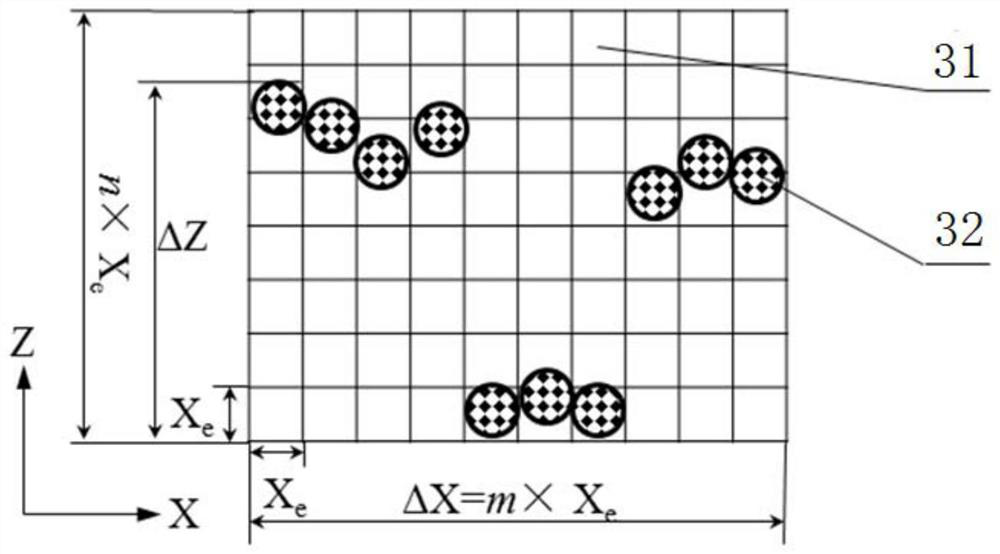

[0023] Discrete sequence points are widely used in the description of weld contour features, these sequence points contain the contour information of the weld, but only by sorting out the relative geometric position relationship between each point, it is possible to quantitatively describe the weld seam features. The straight line is a common form in the weld profile, and the efficient and accurate fitting of the line feature through offline sequence points is a common problem faced in the weld profile detection, and it is also a difficult problem that the present invention focuses on solving.

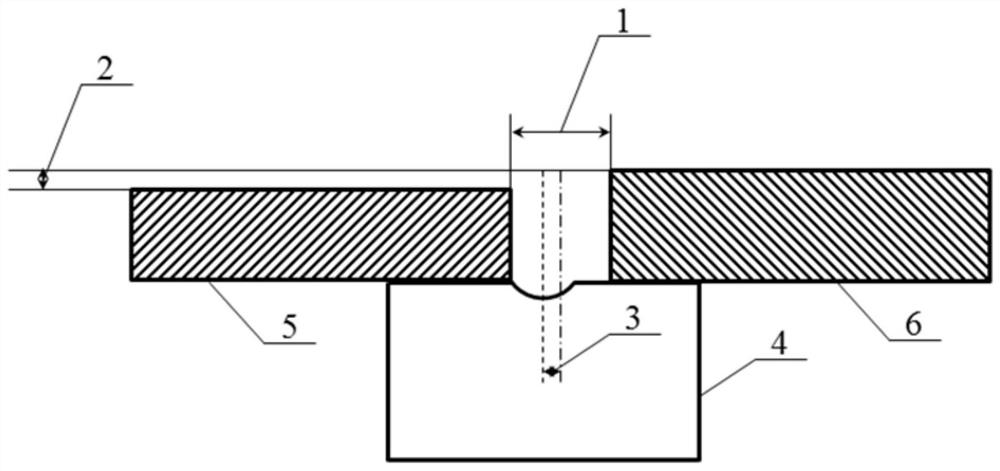

[0024] The invention proposes a method for detecting weld seam contour features. This method takes the discrete sequence points containing weld contour information as input, maps the relevant discrete points to pixels on the grayscale bitmap, constructs straight lines on the bitmap through computer vision algorithms, and calculates the geometric relationship between the related straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com