A method and device for quickly screening size defects of metal parts

A metal part and metal technology, which is applied in the field of rapid screening of metal parts for dimensional defects, can solve the problems of unadjustable detection accuracy, high cost, low detection efficiency, etc., and achieve accurate and reliable detection results, little influence of external factors, and acceptable detection accuracy. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

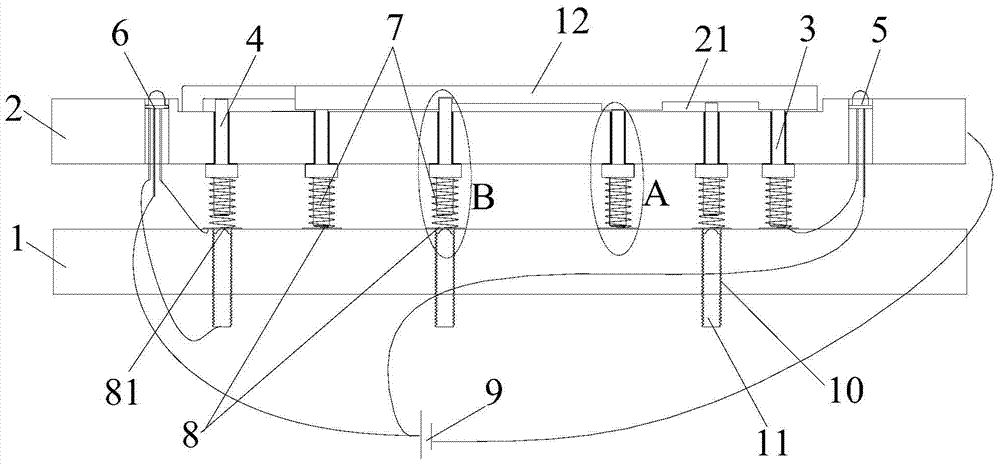

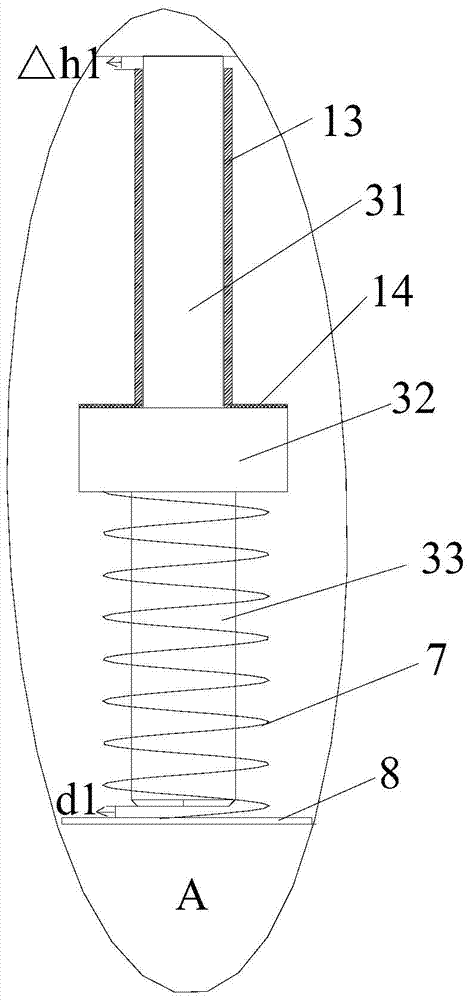

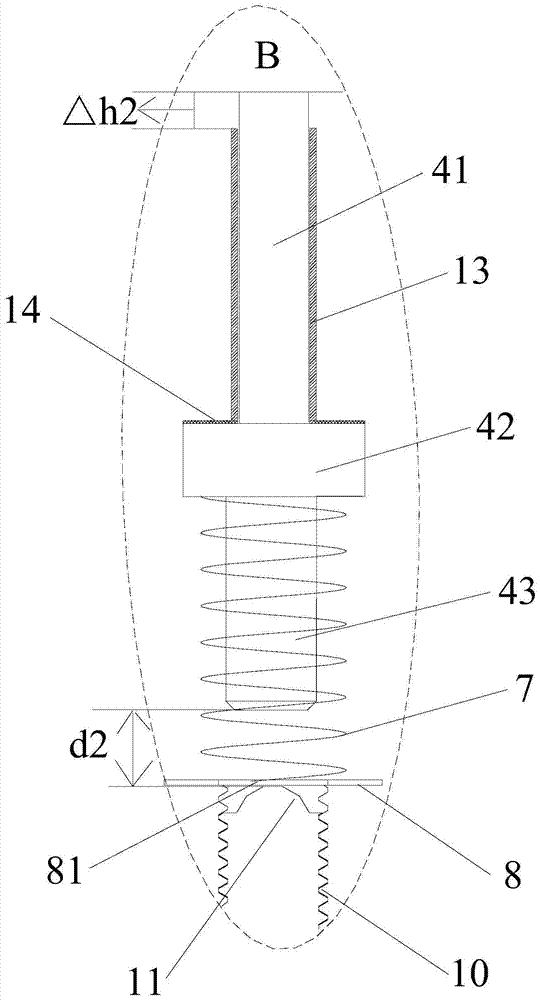

[0024] Combine Figure 1 to Figure 3 Shown: This embodiment provides a device for rapidly screening dimensional defects of metal parts, which includes a base 1 and a conductive metal platform 2. The conductive metal platform 2 is provided with a detection area 21 in the detection area 21 There are a number of flatness detection metal floating contacts 3 and a number of height detection metal floating contacts 4; a number of single-color indicator lights 5 and a number of two-color indicator lights 6 are provided on the conductive metal platform 2 located on the outer periphery of the detection area 21; The flatness detection metal floating contact 3 and the height detection metal floating contact 4 are both insulated and penetrated on the conductive metal platform 2 in the detection area 21, and springs 7 are sleeved on the positions below the conductive metal platform 2. The bottom ends of the springs 7 all collide with the conductive metal sheets 8 provided on the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com