Siphon nano-biosensing chip and preparing method thereof

A bio-sensing and chip technology, applied in the field of medical testing, can solve the problem that the accurate measurement cannot exceed 20%, and achieve the effect of ideal linearity and repeatability, improved response sensitivity and accuracy, and significant substantive characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

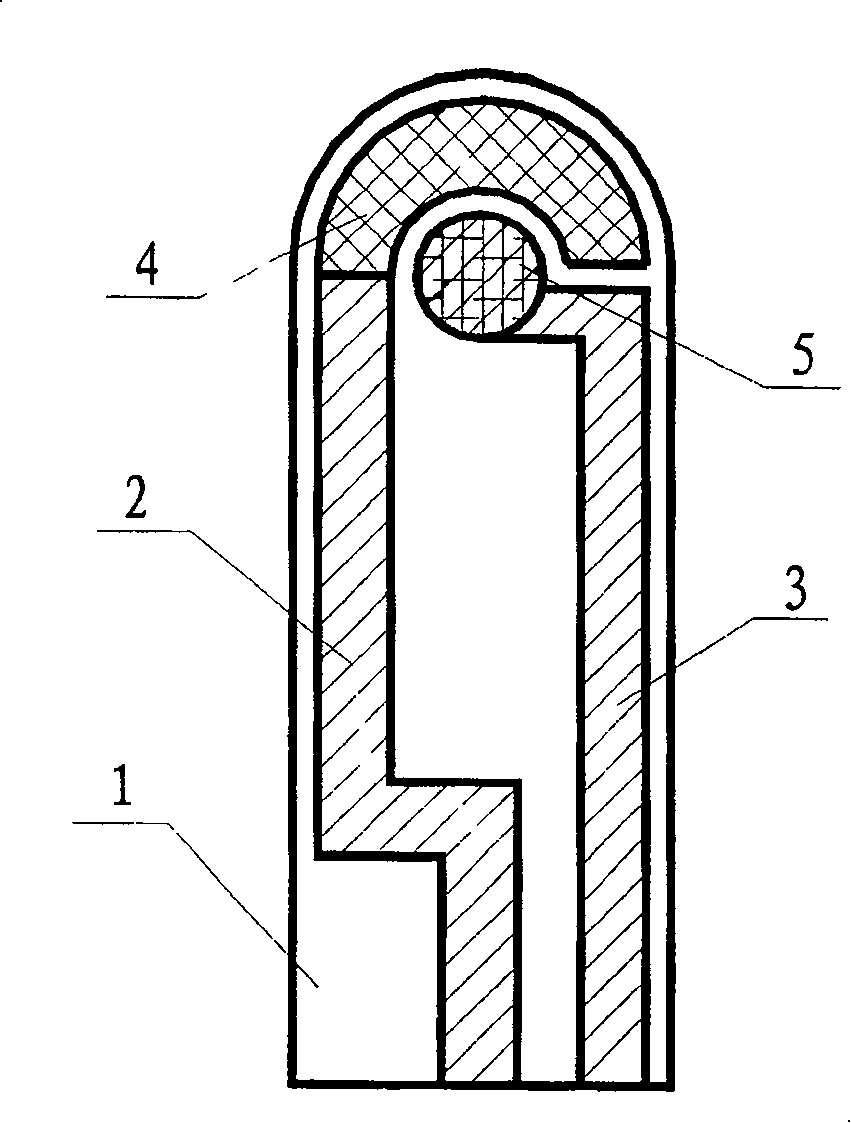

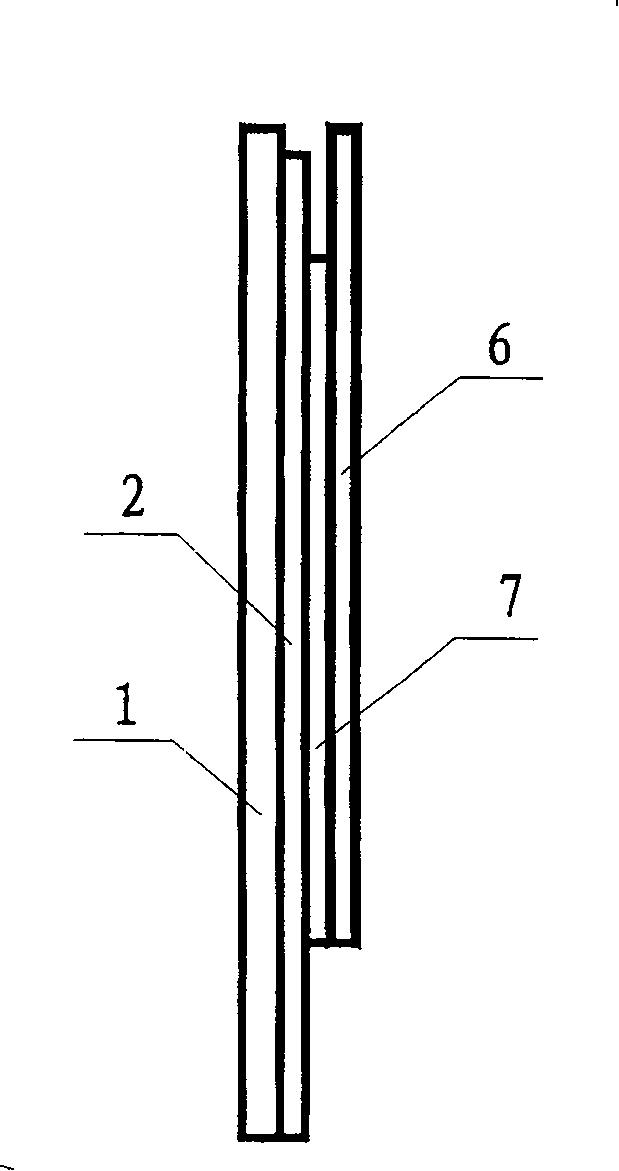

[0042] The siphon nano biosensor chip of this embodiment is used for testing blood sugar, figure 1 and figure 2 As shown, it is mainly composed of two adjacent graphite electrodes 2, 3 attached to the substrate 1, and a reference electrode 4 attached to the front ends of the two graphite electrodes respectively (the reference electrode can also completely or partially cover the entire chip graphite electrode) and work The enzyme electrode 5 is formed (the rear end of the enzyme electrode can also be completely or partially covered by other materials with better conductivity than graphite, such as the reference electrode material used). The base material is double-oriented PET (polyethylene terephthalate), and the upper surface of each electrode is covered with a protective transparent, translucent or opaque PET plastic film 6 bonded by an adhesive layer 7 .

[0043] The specific process of its production is as follows:

[0044] 1), preparation of nano-graphite electrode slu...

Embodiment 2

[0075] The basic structure of the biosensor of this embodiment is the same as that of Embodiment 1, and the specific preparation process is as follows:

[0076] 1), preparation of nano-graphite electrode slurry

[0077] 1-1 Dissolve 15% polyacrylic acid and 15% polyamide in 70% mixed solvent (petroleum cracking aromatic organic solvent), and dissolve slowly for 2-3 hours at 50-60°C to prepare a polymer solution;

[0078] 1-2 Fully mix the prepared polymer solution and nano-scale graphite in a three-roll internal mixer, and the shearing force is continuously increased until the particle size of the dispersed phase reaches the nano-scale;

[0079] 1-3 Use mixed solvent to adjust the viscosity to 20-60Pa.s.

[0080] 2), preparation of reference electrode slurry

[0081] 2-1 is the same as 1-1;

[0082] 2-2 Fully mix the prepared polymer solution with 68% nano-scale silver and silver chloride (ratio Ag:AgCl=70:30) in a three-roll internal mixer, and the shearing force is contin...

Embodiment 3

[0097] The basic structure of the biosensor of this embodiment is the same as that of Embodiment 1, and the specific preparation process is as follows:

[0098] 1), preparation of nano-graphite electrode slurry

[0099] 1-1 Dissolve 15-30% methacrylic acid, n-butylacrylic acid copolymer and 5-10% polyvinyl acetate in 70% mixed solvent (petroleum cracking aromatic organic solvent) at 50-60°C , slowly dissolve for 2-3 hours to prepare a polymer solution;

[0100] 1-2 Evenly mix the prepared polymer solution and graphite powder;

[0101] 1-3 Use mixed solvent to adjust the viscosity to 20-60Pa.s.

[0102] 2), preparation of reference electrode slurry

[0103] 2-1 is the same as 1-1;

[0104] 2-2 Fully mix the prepared polymer solution with 50-70% nano-scale silver and silver chloride (ratio Ag:AgCl=60:40) in a three-roll internal mixer, and the shearing force is continuously increased until The particle size of the dispersed phase reaches the nanometer level, and a conductiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com