Refrigerating device of belt steel and cooling and controlling method thereof

A cooling device and strip steel technology, applied in the field of metallurgy, can solve the problems of limited increase in water volume in the strong cooling group, inability to realize rapid cooling function, and inability to realize controlled cooling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

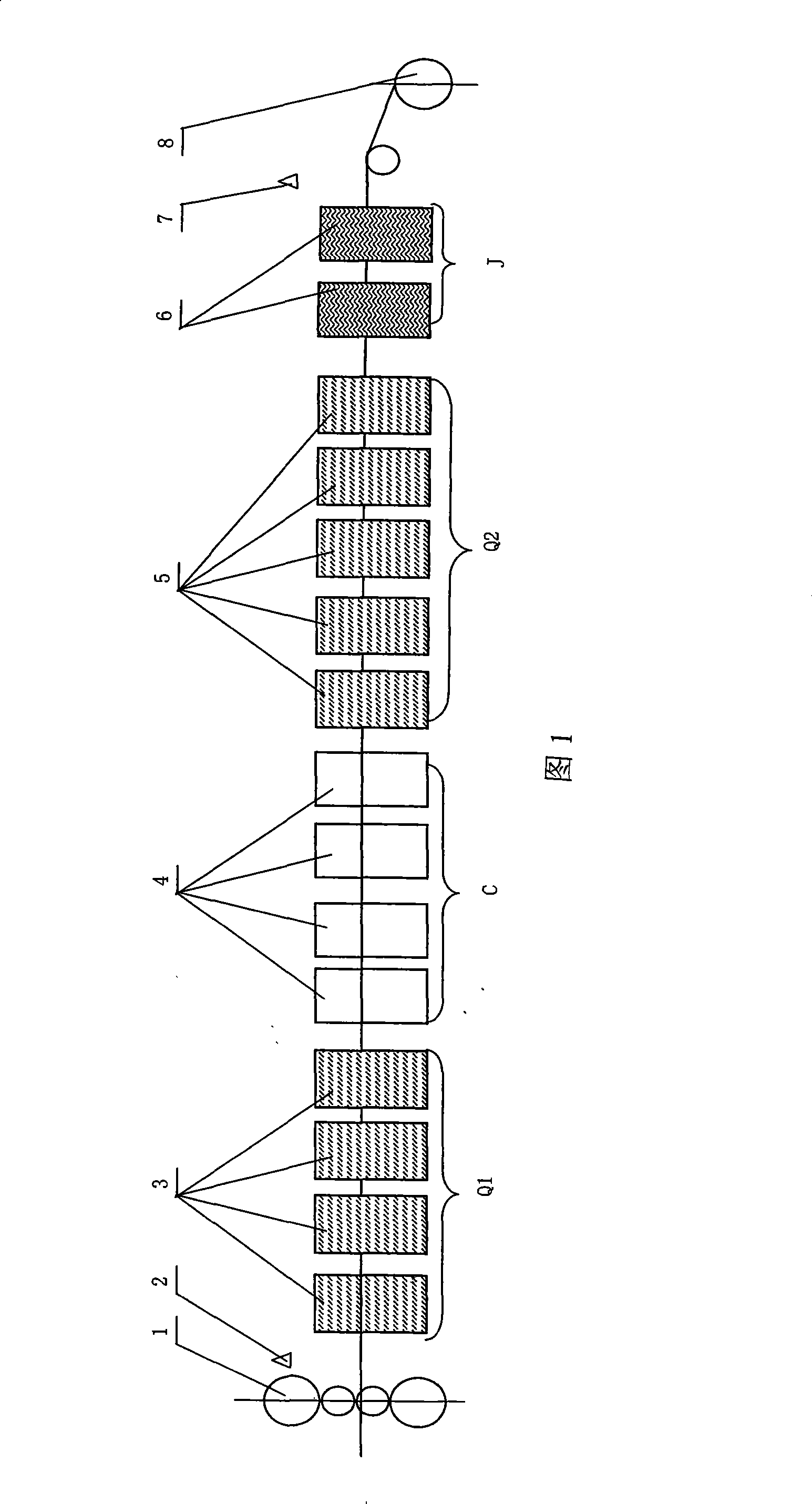

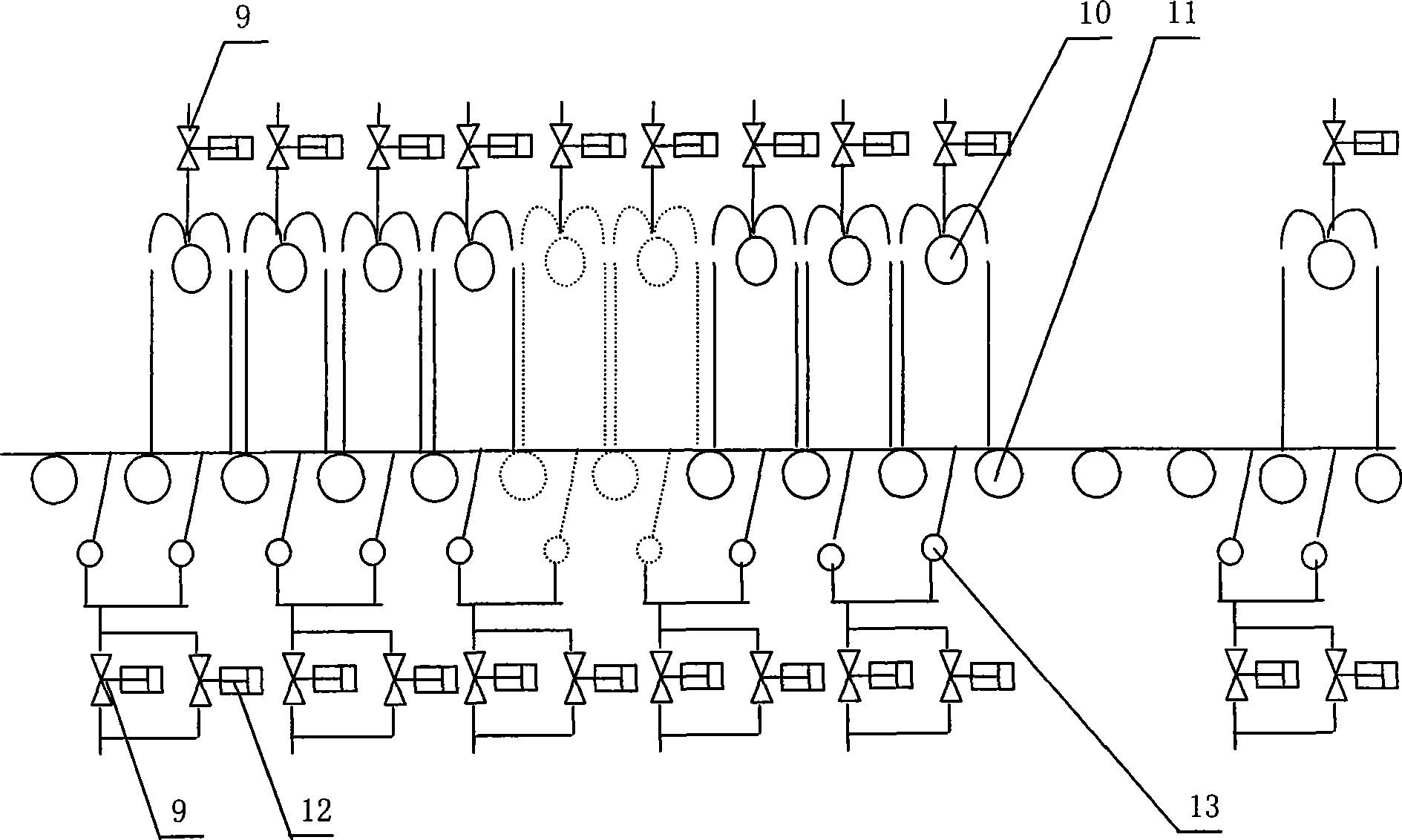

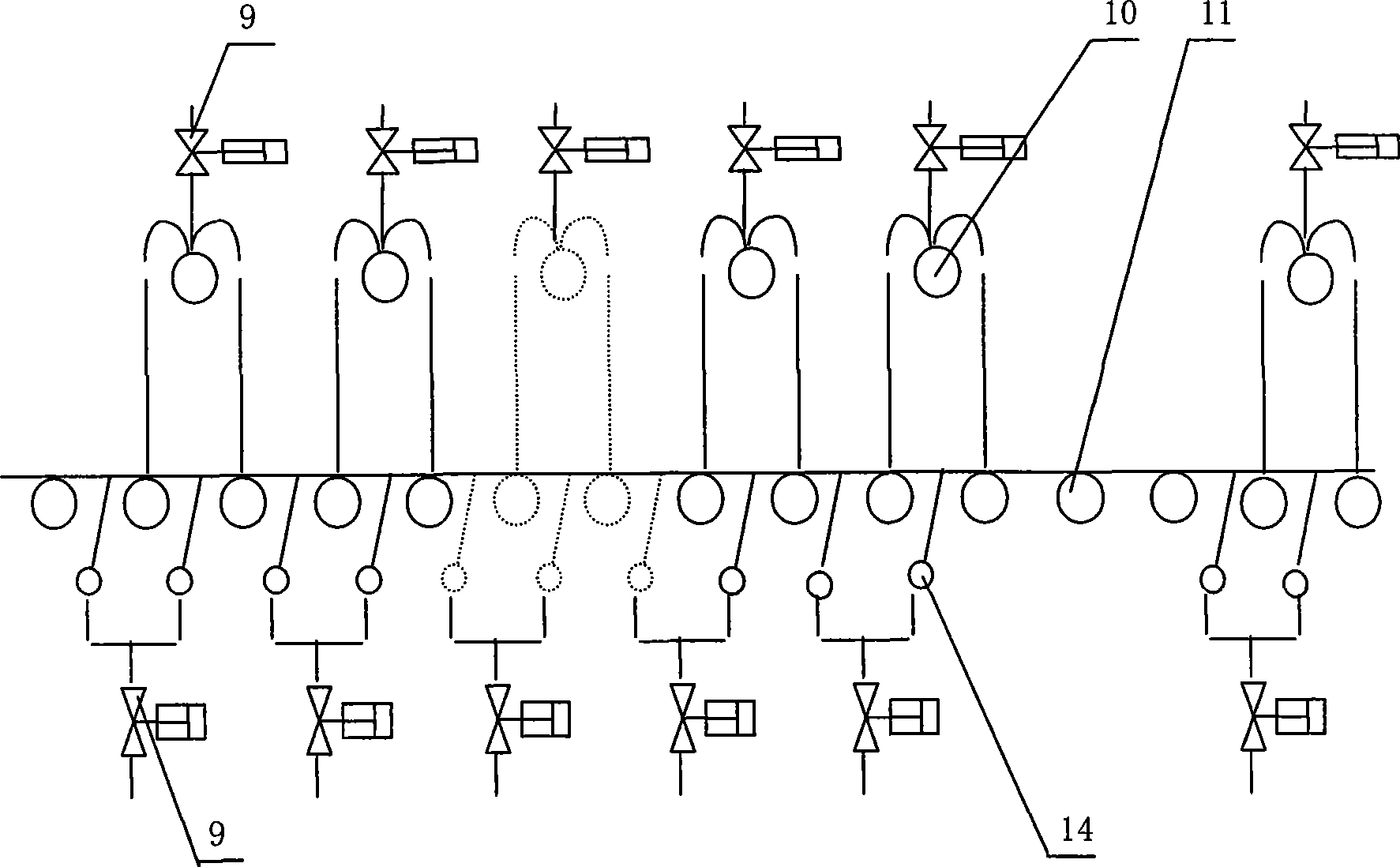

[0034] After the hot-rolled strip is rolled by the last stand mill 1 of the finishing rolling unit, it is sent to the cooling zone by the strip conveying roller table 11. In order to realize the coiling temperature feed-forward and feedback control and improve the coiling temperature accuracy of the hot-rolled strip, the cooling The entrance and exit of the device are respectively provided with strip temperature detection devices 2 and 7 , and the cooled strip enters the coiler 8 . The cooling zone is composed of a powerful cooling zone Q (Q1, Q2), a coarse cooling zone C and a fine cooling zone J, and each cooling zone is composed of several cooling sections. Each cooling section has the same length and is composed of an upper laminar flow cooling header and a lower injection header. Side spray devices are installed between each cooling section t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com