Strip steel surface defect on-line intelligent identification and detection system and detection method

A technology of intelligent identification and detection method, which is applied in the direction of optical defect/defect, image data processing, instrument, etc., can solve the problem of single detection method of strip steel surface defect detection technology, achieve precise classification accuracy, optimize acquisition and imaging technology, the effect of eliminating the interference of imaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

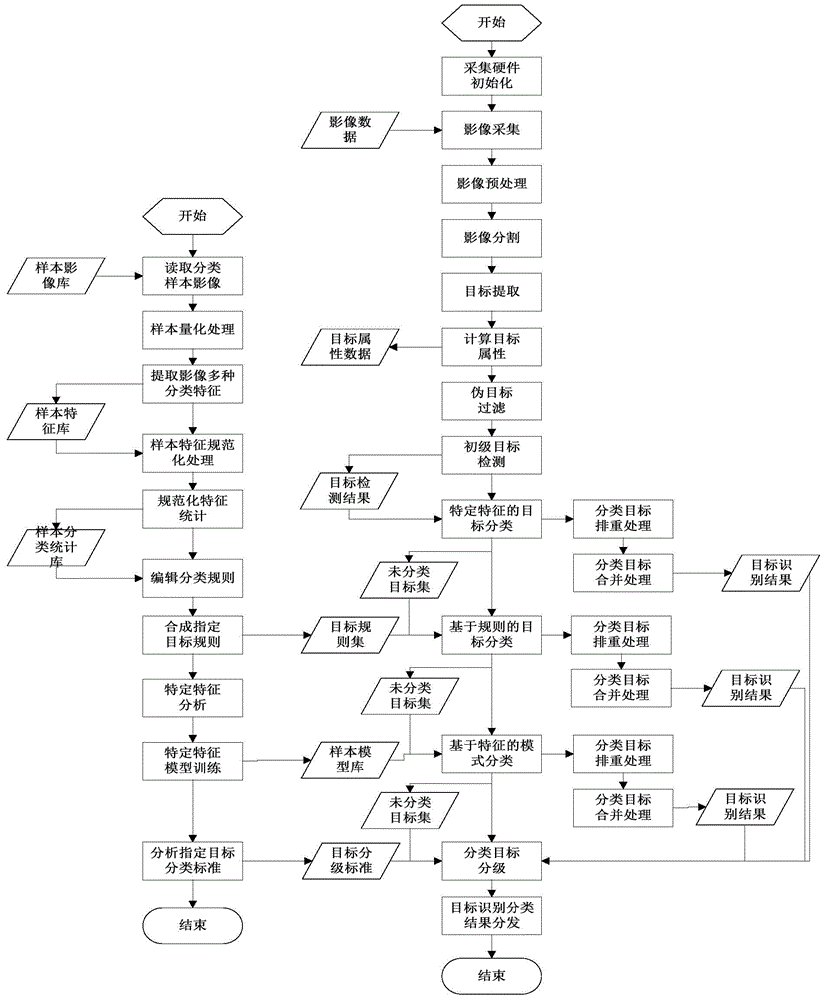

[0034] figure 1 It is a flow chart of target sample simulation training and defect detection and identification in this embodiment. The online intelligent identification and detection method for steel strip surface defects comprises the following steps,

[0035] Step 101 The light source irradiates the upper and lower surfaces of the steel strip, and the original image of the surface of the steel strip is collected by a high-speed linear array CCD, and the collected original defect image is converted into digital information and then transmitted to the image processor;

[0036] The identification and detection method of this embodiment optimizes the collection and imaging technology of defect images, adopts the image imaging method of high-speed line array camera and linear monochromatic light source, and can collect clear defect images; at the same time, the optical correction function based on statistics can effectively eliminate defects The interference of the external env...

Embodiment 2

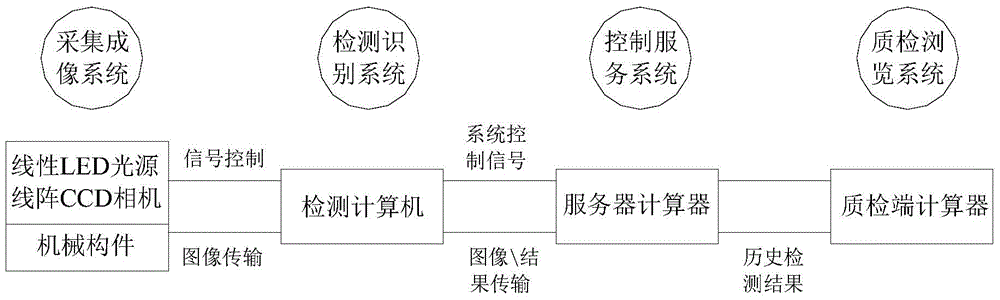

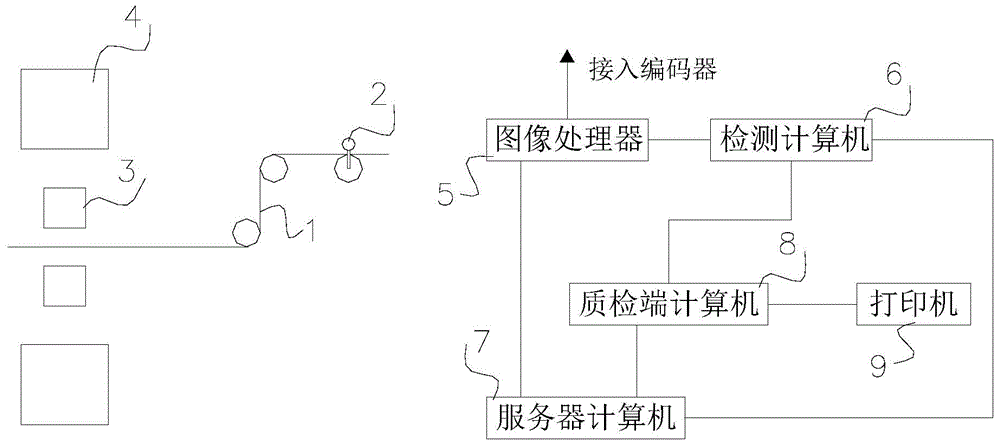

[0051] Figure 4 It is a working principle diagram of the online intelligent identification and detection system for steel strip surface defects in this embodiment. The system including the system of this embodiment is divided into four levels: an imaging acquisition system, a detection and identification system, a control service system, and a quality inspection browsing system.

[0052] Among them, the acquisition system includes lighting system, imaging system, mechanical structure and three-proof system. The detection and identification system includes several defect detection computers. The detection and identification system controls the light source, camera control and system status monitoring of the imaging acquisition system. Data collection and transmission. The detection and recognition system detects and recognizes defects through head and tail detection, weld detection, hardware control, defect detection, defect filtering, defect merging, defect classification, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com