Band-steel laminar-flow cooling device and its cooling control method

A laminar flow cooling device and controlled cooling technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of difficult control of cooling rate, unreasonable header structure, poor temperature control accuracy, etc., and achieve improved The effect of cooling control precision, complex combination, and strong cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The strip laminar flow cooling device and its control cooling method of the present invention will be further described below with reference to the accompanying drawings.

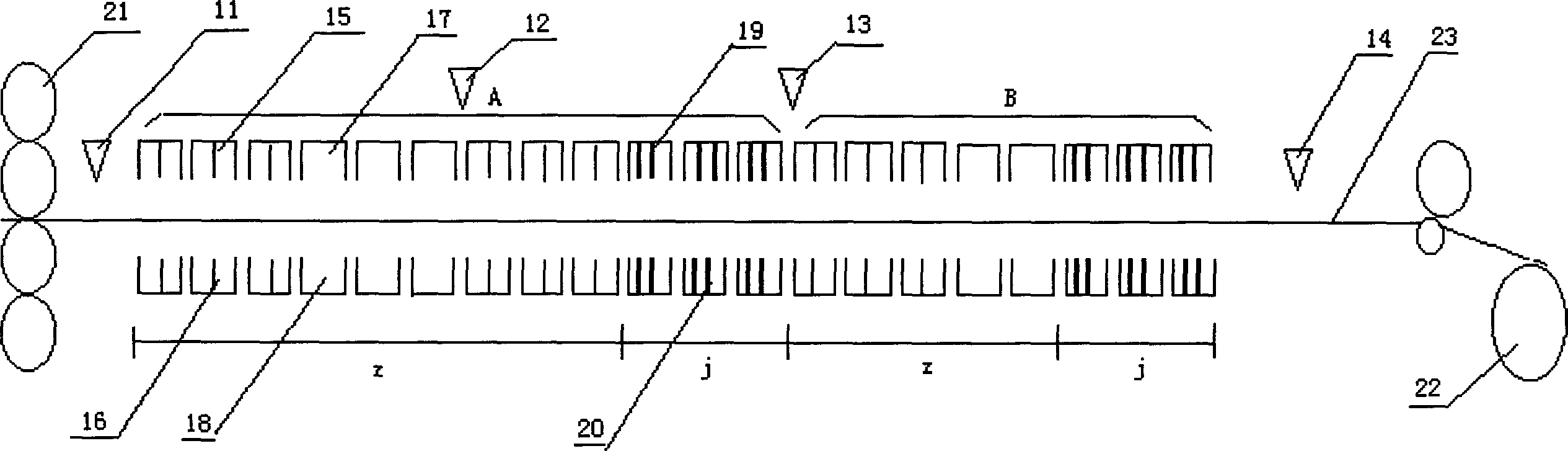

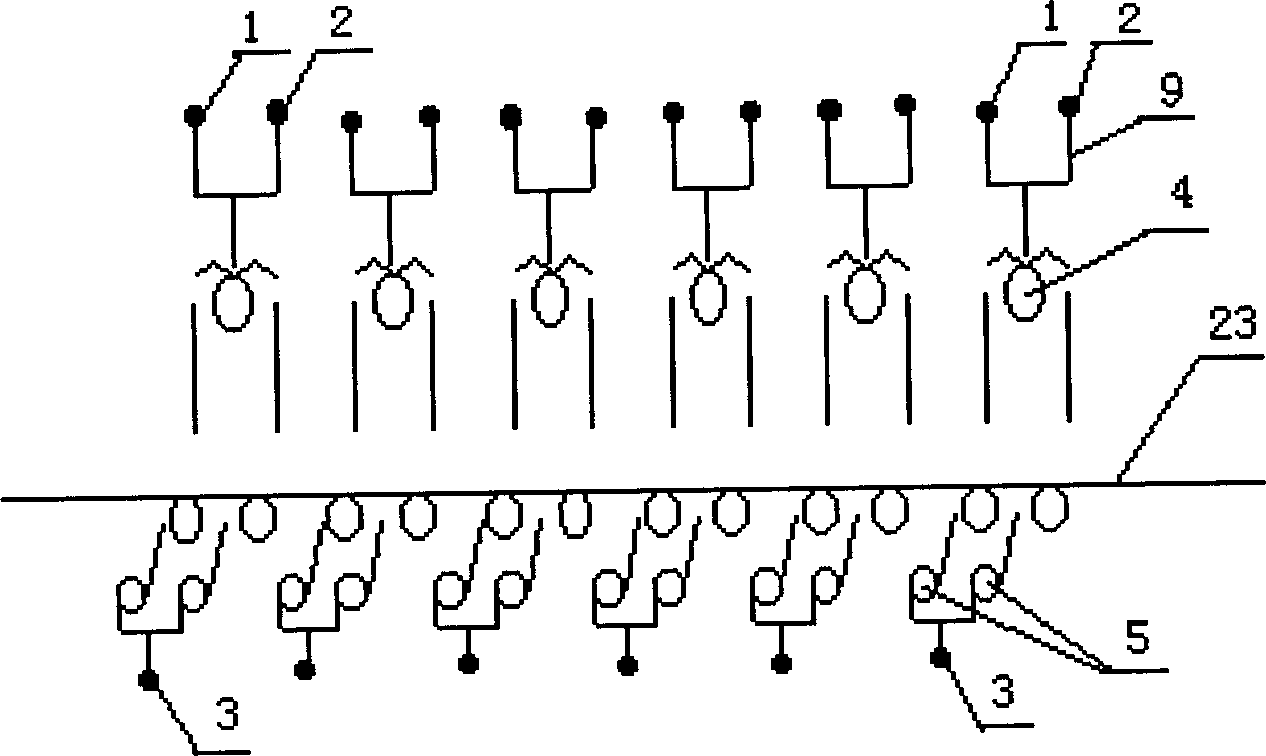

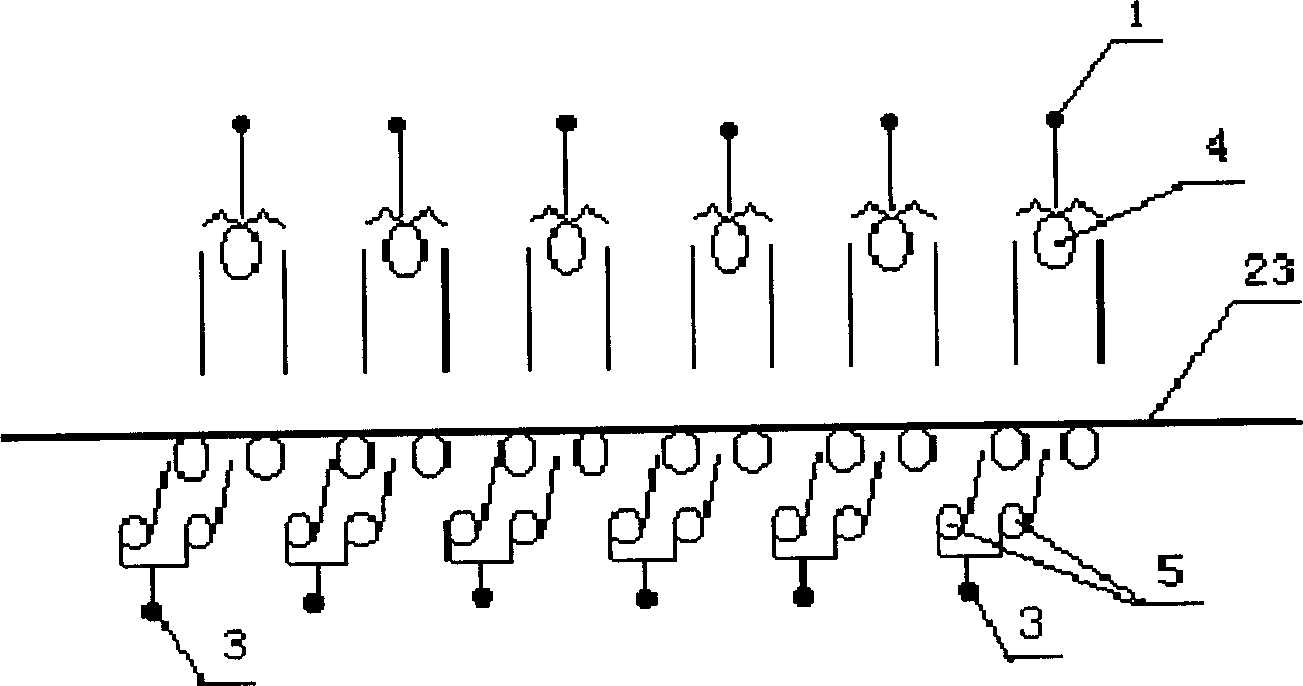

[0012] The strip steel laminar flow cooling device of the present invention is mainly composed of a cooling zone composed of several upper laminar flow header groups and a corresponding number of lower spray header groups, and is the same as the existing laminar flow cooling device. The side is provided with a side blowing mechanism along the length of the cooling zone. attached figure 1 It is a specific embodiment of the present invention. 23 is strip steel among the figure. It can be seen from the drawings that the cooling device is composed of two cooling zones with their own main cooling section Z and finishing cooling section J, that is, the front cooling zone A and the rear cooling zone B are connected in series, and its structural form is : main cooling section Z + finishing cooling section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com