Strip steel surface area type defect identification and classification method

A technology for surface area and defect recognition, applied in character and pattern recognition, instruments, computer parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

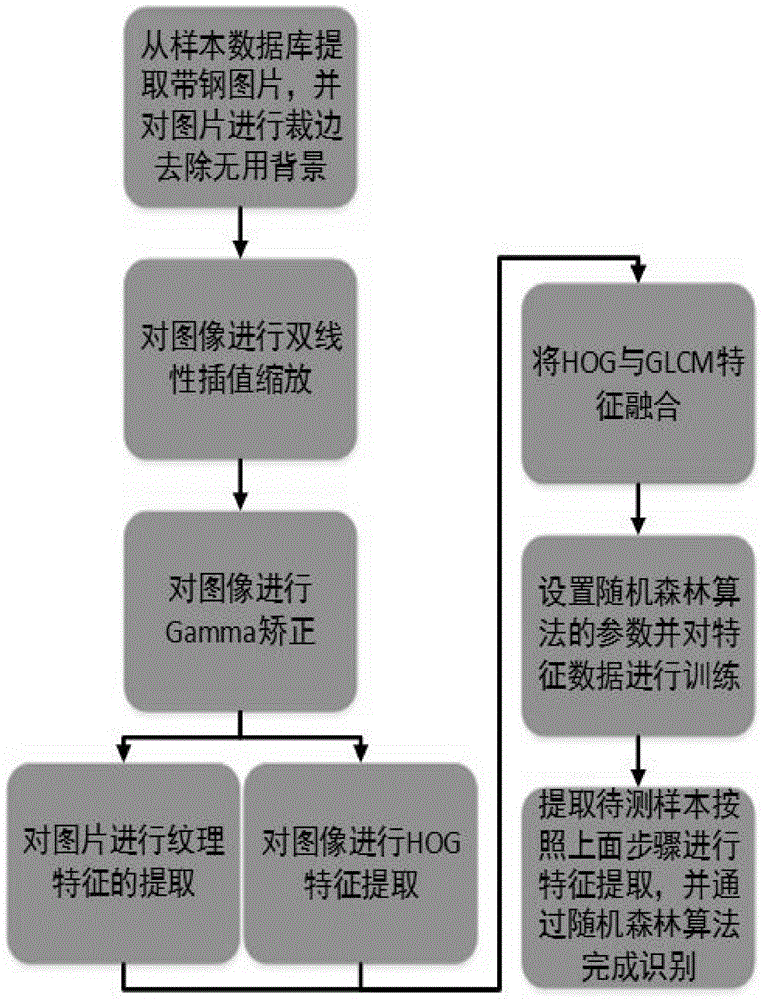

[0053] A method for identifying and classifying strip surface area defects of the present invention, the process is as follows figure 1 shown, including the following steps:

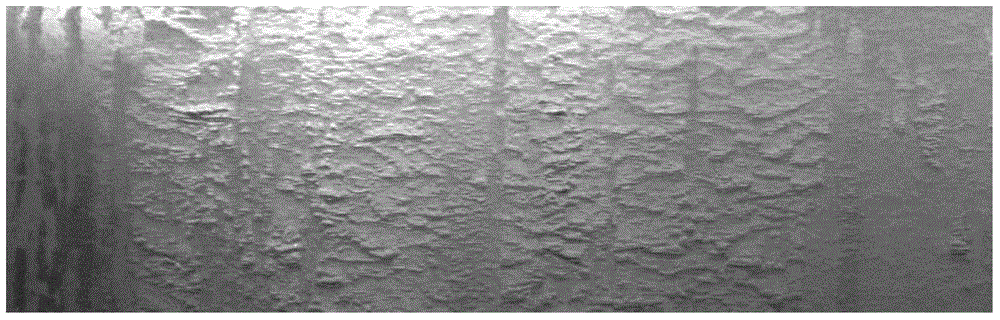

[0054] Step 1: Extract the strip steel surface picture from the training sample library, cut the picture with a fixed width and height to remove the useless background of the non-strip steel surface in the picture, so that only the strip steel surface remains in the obtained picture, such as figure 2 shown. And save the category to which the picture belongs to the corresponding label matrix.

[0055] Step 2: Sampling the picture with bilinear interpolation algorithm, and scaling it to a width and height of 64 pixels by 64 pixels. Experiments show that the effect of feature retention after processing is the best, and it greatly shortens the time for subsequent recognition. The size can be determined according to The original camera image is adjusted, such as image 3 Shown; Wherein the bilinear inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com