Shrimp-crab meat collecting method and shrimp-crab meat collecting equipment

A collection method, technology of shrimp and crab, applied in the field of food processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] When collecting shrimp and crab meat, add water 3 times the weight of shrimp and crab scraps to facilitate the separation of shell and meat, as well as 2% ascorbic acid and 0.03% bamboo leaf antioxidants to prevent shrimp and crab meat from being damaged during the collection process. Oxidation of saturated fatty acids degrades the quality of shrimp and crab meat, and then the following equipment is used to crush and crush. The shrimp and crab waste is broken and separated into shrimp and crab meat and shrimp and crab shells.

Embodiment 2

[0036] When collecting shrimp and crab meat, add water with a weight equal to 1 times the weight of the shrimp and crab scraps to facilitate the separation of the shell and meat, and 2% sodium erythorbate and 2% tea polyphenols to prevent the shrimp and crab meat from being damaged during the collection process. Oxidation of saturated fatty acids makes the quality of shrimp and crab meat worse, and then the following equipment is used to squeeze and crush the shrimp and crab waste. After the shrimp and crab scraps are broken, they are separated into shrimp and crab meat and shrimp and crab shells. , and then separate the meat and the shell with the shell meat separation equipment.

[0037] Examples of extrusion equipment are as follows:

[0038] Example 1

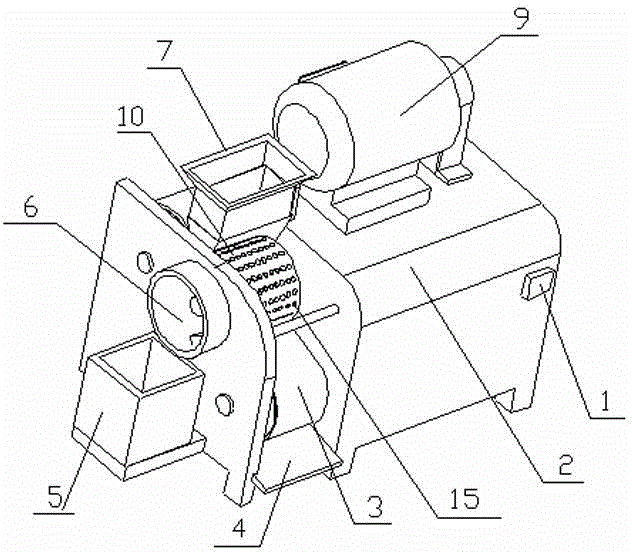

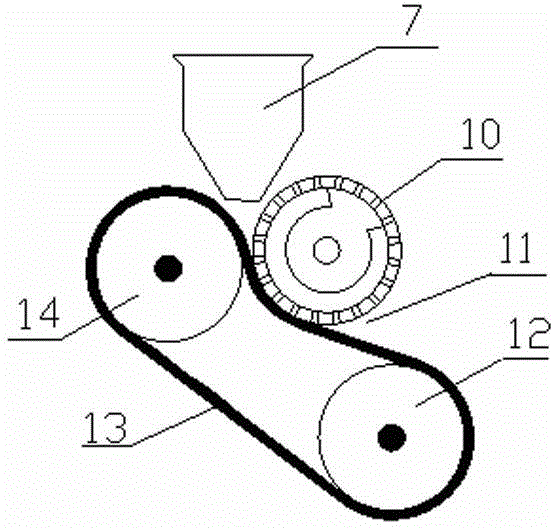

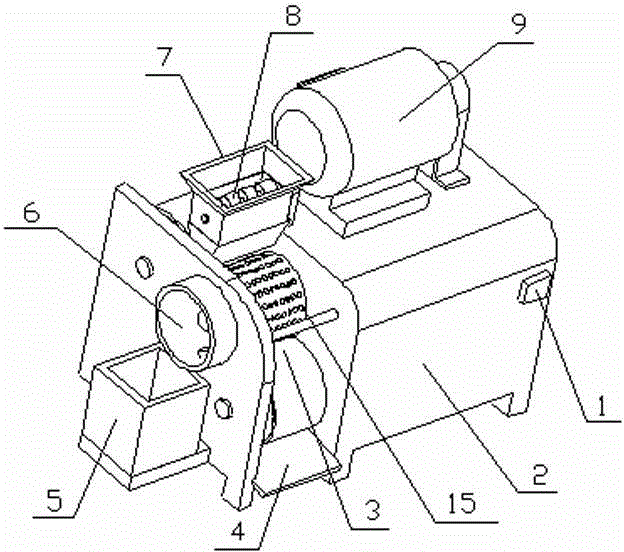

[0039] Such as figure 1 The extrusion equipment shown includes a switch 1, a body 2, a rolling wheel set 3, a shell outlet 4, a meat storage barrel 5, a meat outlet 6, a hopper 7, and a motor 9, wherein the rolling wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com