Method of united optimized managing contracts and repertories in plane of steel production

A technology of production planning and management methods, which is applied in computing, electrical digital data processing, special data processing applications, etc., and can solve problems such as unchecked patent documents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

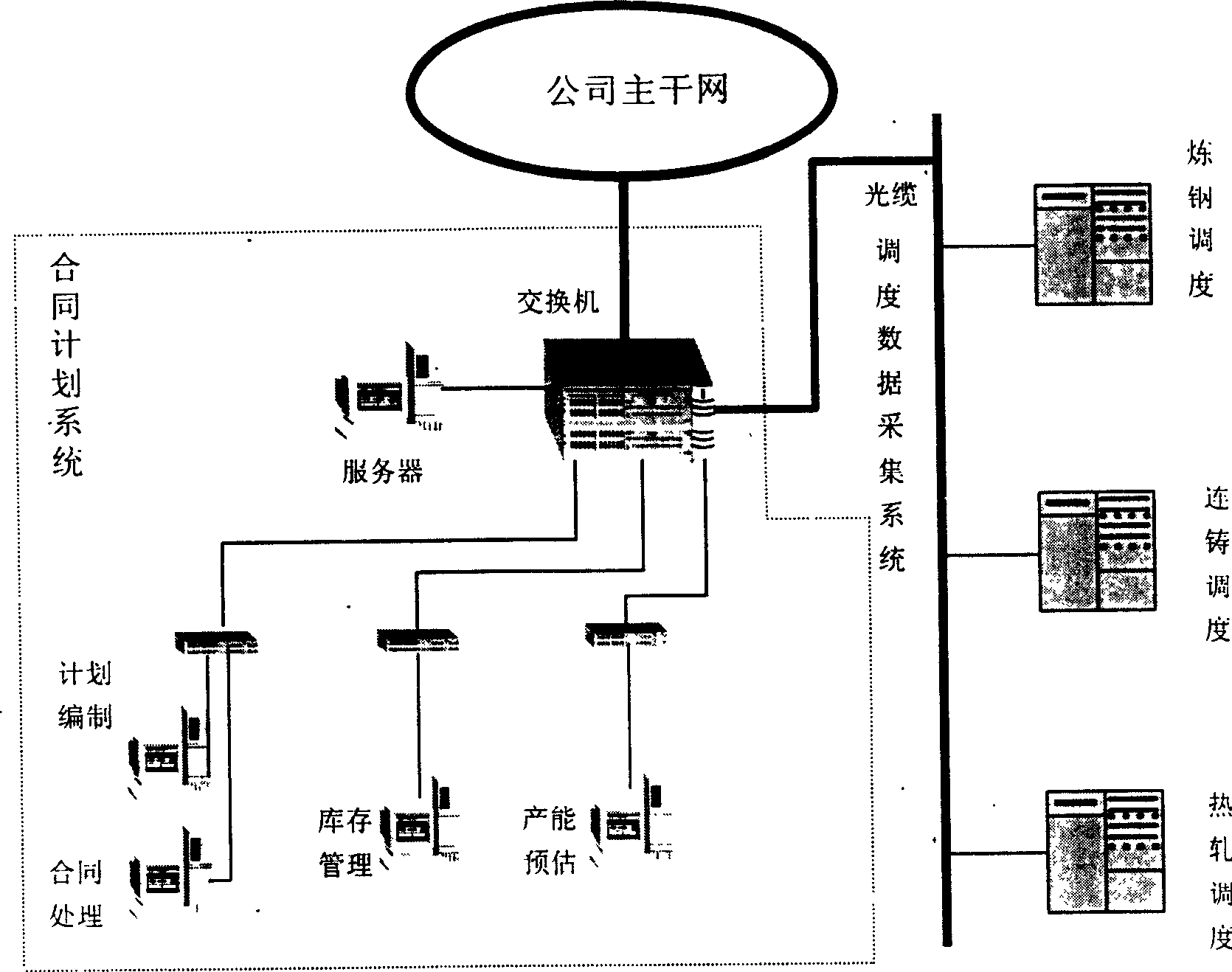

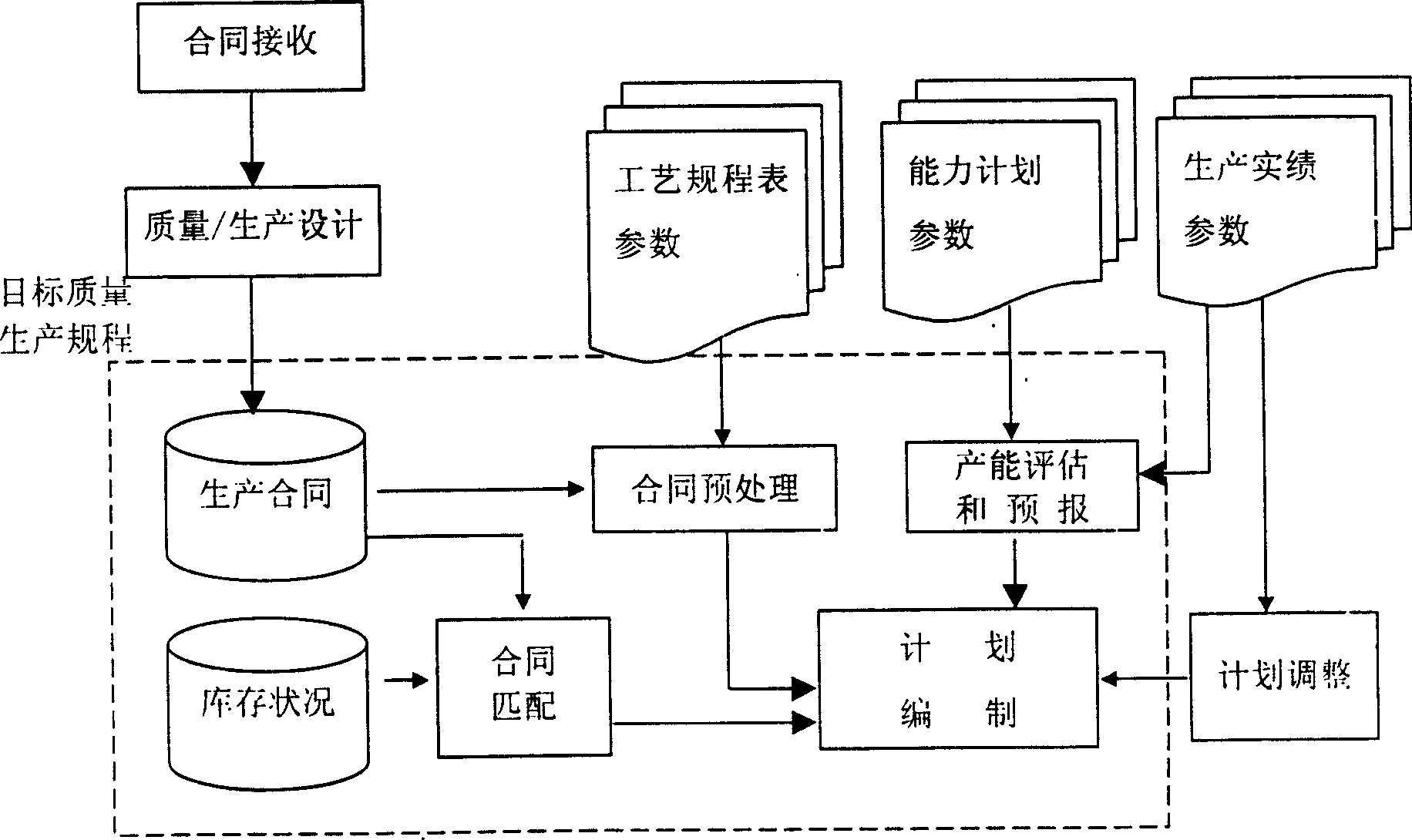

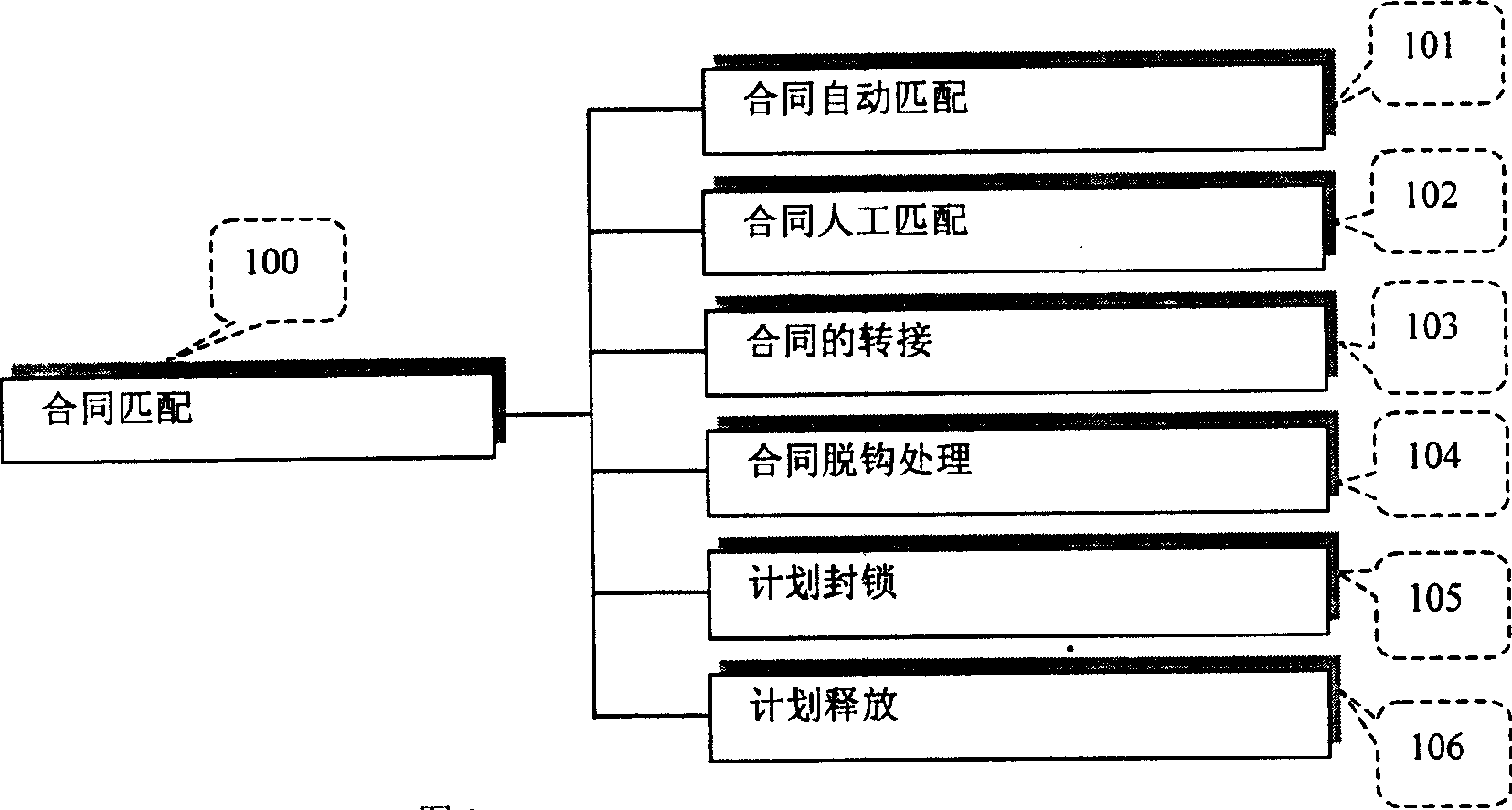

Method used

Image

Examples

Embodiment Construction

[0100]In order to verify the validity of the model and the algorithm, the simulation of several groups of problem instances is carried out, and a relatively ideal result is obtained. In the following, the simulation experiment is carried out by using this method in the background of the hot delivery and loading process in a certain iron and steel enterprise. Combined with the actual situation of the enterprise, steel production goes through the four processes of steelmaking-refining-continuous casting-hot rolling in sequence, and the process path is the same. The rated production capacity of the entire process is based on the capacity of the "bottleneck" process. It is known that the scope of the planning period is 1 month, and the time period is divided by ten days, so T=3. The example selects three groups of data with different scales of contract quantity, rated production capacity and inventory type, as shown in Table 1.

[0101] Table 1 Joint optimizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com