Electrochemical heavy metal detector constructed based on graphene test paper electrode and detection method thereof

An electrochemical and graphene technology, which can be applied in the fields of material electrochemical variables, scientific instruments, metal pattern materials, etc., and can solve the problems of sensitivity and portability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A preparation method of graphene oxide, using chemical oxidation-ultrasonic stripping-chemical reduction method to prepare graphene oxide, and studying the influence of reaction conditions on the quality of synthesized graphene oxide. : We combine some technical improvements on the basis of the Hummers method to prepare graphene oxide. Preparation method The reaction can be divided into three stages, namely: low temperature stage (the temperature is kept in the range of 10~15°C), medium temperature stage (the temperature is kept in the range of 32~38°C) and high temperature stage (the temperature is kept in the range of 98 ℃). Specific steps are as follows:

[0071] Low-temperature stage: First, 230 ml of concentrated sulfuric acid was carefully added to a 2-liter round-bottomed flask, and the round-bottomed flask was cooled to 0° C. in an ice-water bath. A mixture of 10 grams of natural graphite powder and 5 grams of sodium nitrate was then added with rapid stirring....

Embodiment 2

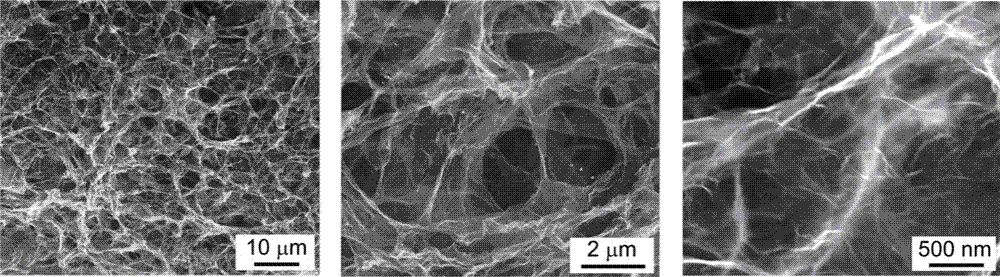

[0088] A method for preparing graphene printed paper electrodes, the principle of which is to use graphene precursor materials—graphene oxide (GO) nanosheets as raw materials to develop a large-scale assembly process for graphene macroscopic materials, relying on GO With its own unique surface functional groups and chemical properties, in the presence of the chemical reducing agent dopamine and under hydrothermal conditions, the reduced GO sheets are stacked and connected to each other, and the GO nanosheets are used as structural units to construct a macroscopic three-dimensional porous graphene assembly. body. The three-dimensional porous graphene assembly not only inherits the excellent properties of two-dimensional graphene nanomaterials such as high electrical conductivity, chemical / thermal stability, and mechanical strength, but also endows it with a unique micro-nanoporous structure and macroscopic structure through its three-dimensional assembly process. by exploring a...

Embodiment 3

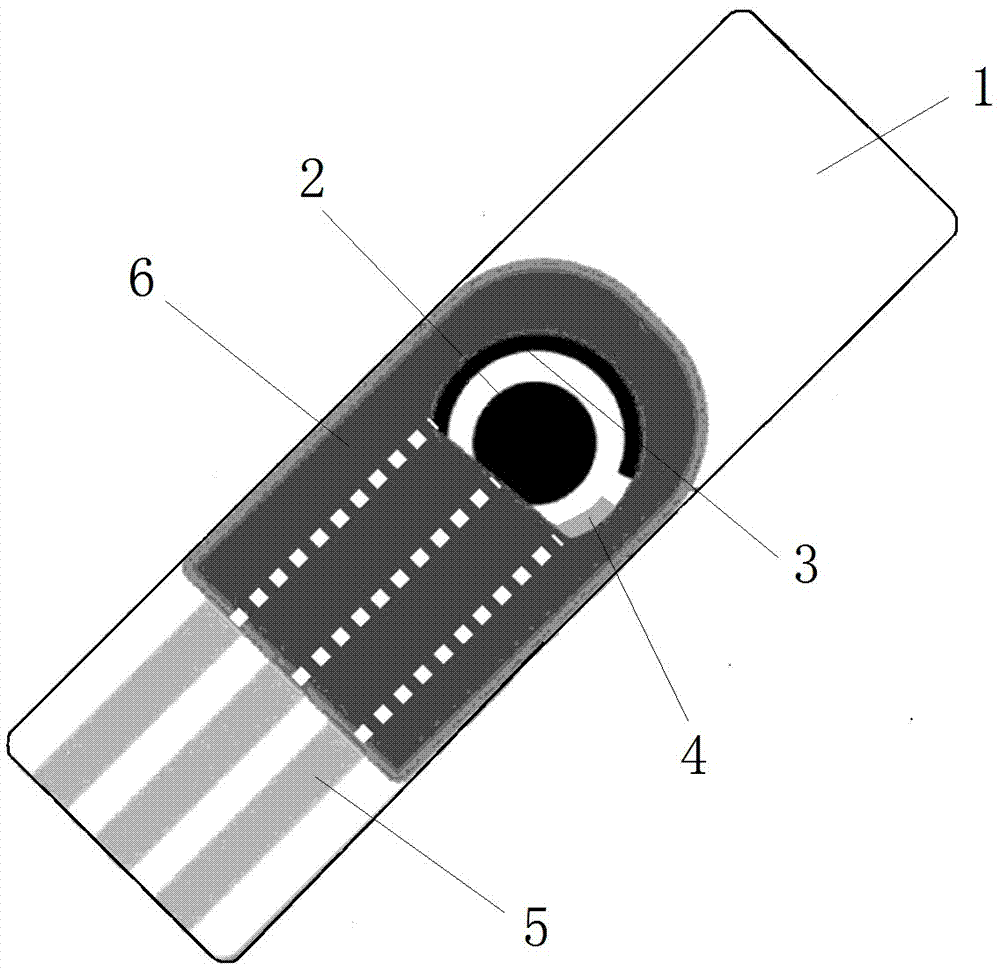

[0098] see figure 1 , a graphene test paper electrode, which includes a PET substrate 1 (polyester film) and a working electrode 2, a counter electrode 3, a reference electrode 4, a silver conductive baseline 5 and an insulating layer 6 printed on it by a printing process; The working electrode 2 is printed graphene, the counter electrode 3 is printed carbon, and the reference electrode 4 is printed silver / silver chloride; The outer periphery and the three are not in contact with each other, the working electrode 2, the counter electrode 3 and the reference electrode 4 are respectively externally connected to the silver conductive baseline 5; the insulating layer 6 surrounds the outer periphery of the counter electrode 3 and the reference electrode 4 and forms a working area inside ; The insulating layer 6 covers the silver conductive base line 5 simultaneously ( figure 1 The continuous white squares in the middle represent the conductive path, that is, the working electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com