Three-layer scratch-resistant PET (polyethylene terephthalate) protective film

A protective film and anti-scratch technology, which is applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problem of only reaching about 3.5H, affecting the transmittance of the protective film, and affecting the display effect of the screen, etc. problem, to achieve the effect of good touch effect, long-lasting performance and easy peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

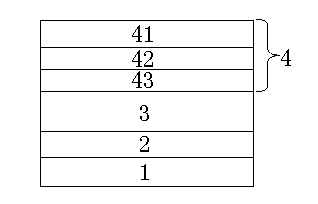

[0015] see figure 1 As shown, embodiments of the present invention include:

[0016] A PET three-layer anti-scratch protective film, comprising: a PET release film 1, a PET substrate 3 and a PET protective film 4, the hardened surface of the PET substrate 3 is attached to the PET protective film 4, and the PET The non-hardened surface of the substrate 3 is attached to the PET release film 1 through the adhesive layer 2, wherein the PET protective film 4 includes a PET protective film substrate 41, a PET protective film adhesive layer 42 and The anti-scratch coating 43, the anti-scratch coating 43 is attached to the hardened surface of the PET su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com