Nanometer scale flexible transparent circuit and preparation process thereof

A preparation process, nano-level technology, applied in the direction of printed circuit manufacturing, printed circuits, printed circuit components, etc., can solve the requirements that the display screen cannot be adapted to the sensitivity and accuracy, the sensitivity and accuracy of the display screen is not high, and the position of the surface changes. Insufficient sensitivity, etc., to achieve the effect of small distance, small width and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

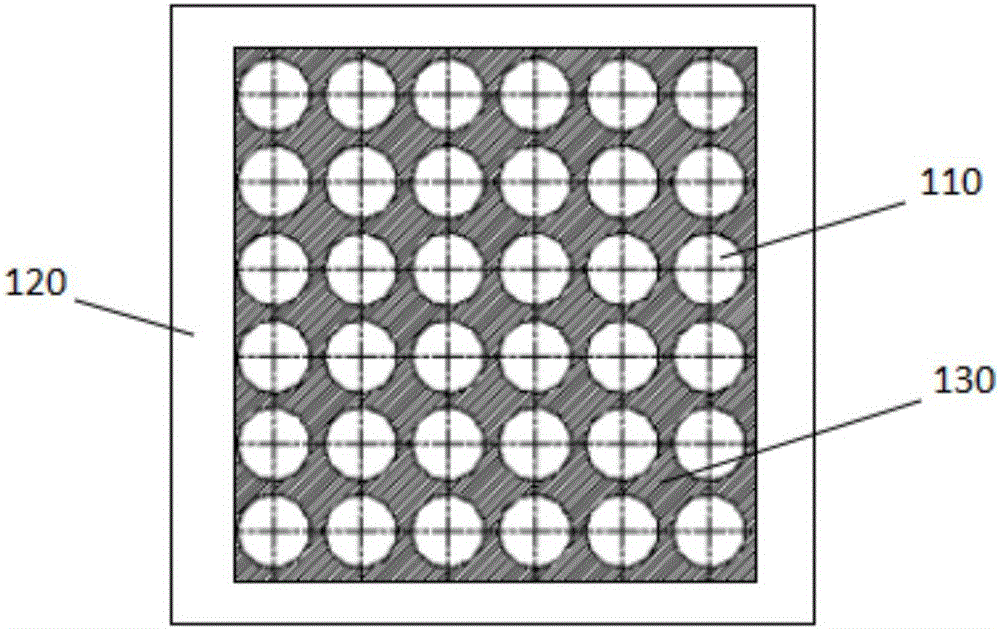

[0032] A nanoscale flexible transparent circuit, its structure is as figure 1 As shown, it is composed of PET base 120 , UV photocurable resin 110 and nano-silver paste 130 , UV photo-curable resin layer 110 is laid on PET base layer 120 , and nano-silver paste 130 fills the structural gap with resin layer 110 . The structure of the UV curable resin 110 adopts a cylindrical structure, the diameter of the cylinder is 700nm, the distance between the centers of adjacent cylinders is 800nm, and the height of the cylinder is 200nm.

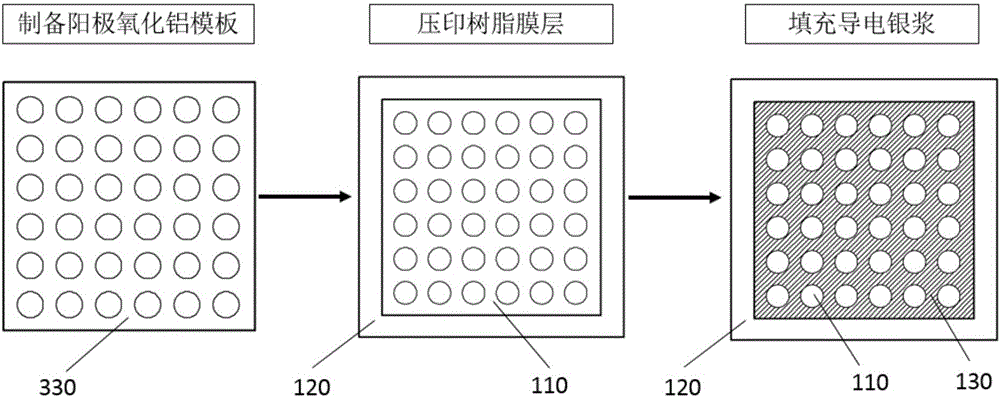

[0033] image 3 and Figure 4 They are respectively the process flow diagram and the schematic diagram of the anodized aluminum template production process of the present invention. The aluminum or aluminum alloy plate 330 is used as the anode, and the carbon rod 310 is used as the cathode. Aluminum oxide film is formed on the surface of 330, so that the nanoporous anodized aluminum oxide film and aluminum without anodic oxidation form a roll-to-roll...

Embodiment 2

[0037] A nanoscale flexible transparent circuit, its structure is as figure 1 As shown, the difference from Embodiment 1 is that in this embodiment, a layer of UV curable resin layer 110 is laid on the surface of the PET layer 120 by a flat pressing process, and finally the conductive silver paste 130 is filled in the gaps of the resin structure.

Embodiment 3

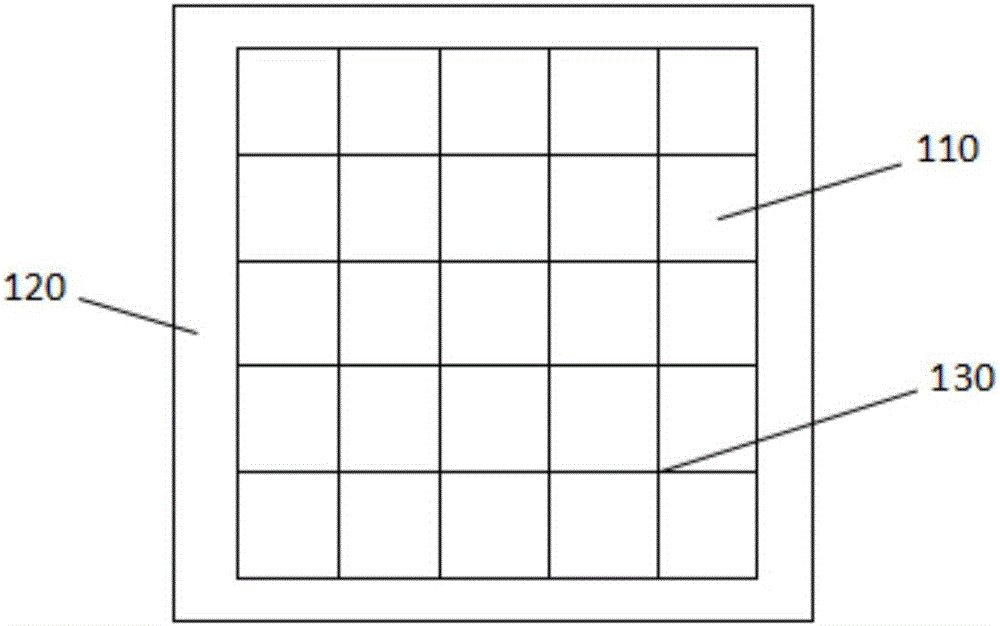

[0039] A nanoscale flexible transparent circuit, its structure is as figure 2 As shown, it is roughly the same as in Example 1, except that the resin structure in this embodiment adopts a quadrangular prism structure, the bottom side length of the quadrangular prism is 400nm, the center-to-center distance between adjacent quadrangular prisms is 450nm, and the height of the quadrangular prism is 500nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Groove width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com