Double-interface intelligent card manufacture process and double-interface intelligent card

A dual-interface smart card and manufacturing process technology, which is applied to recording carriers used in machines, instruments, computer components, etc., can solve the problems of potential safety hazards, high production costs, and low production efficiency, and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Hereinafter, the present invention will be more clearly and completely described with reference to a preferred embodiment and in conjunction with the accompanying drawings.

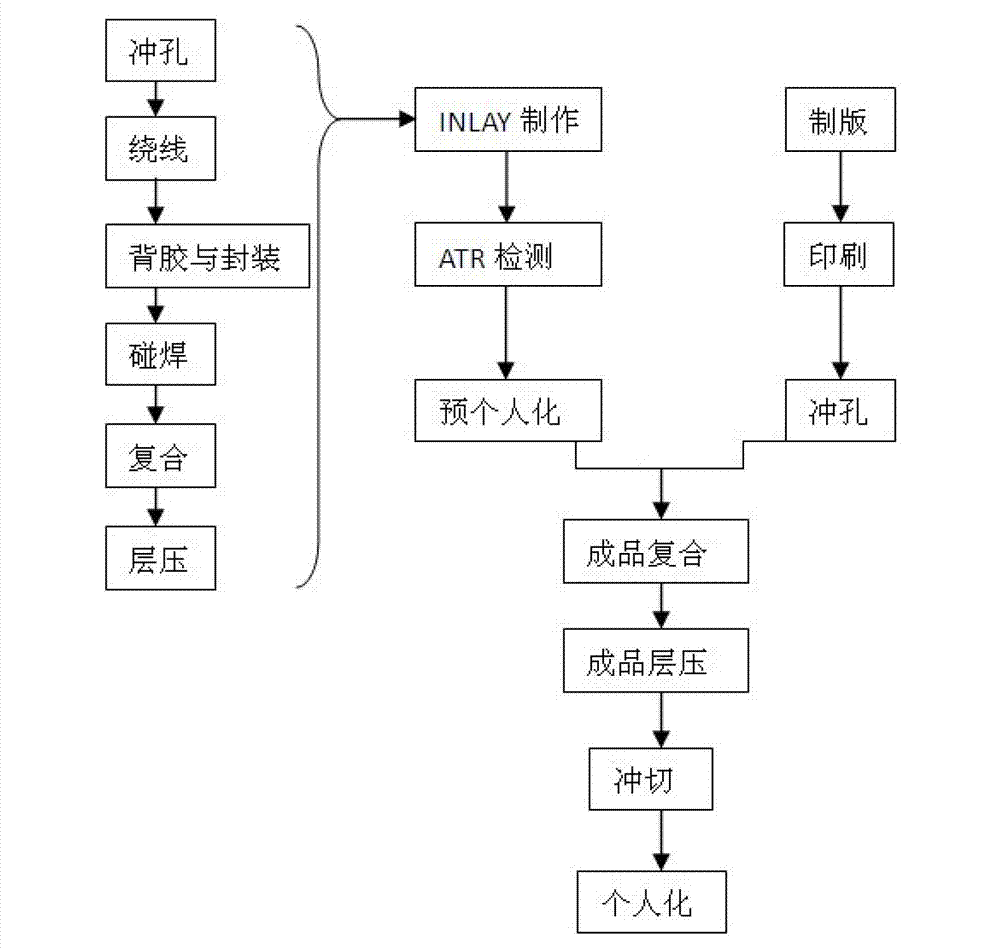

[0051] The invention provides a double-interface smart card manufacturing process and a double-interface smart card. like figure 1 As shown, the dual-interface smart card manufacturing process can be divided into the following steps:

[0052] 1. Production, testing and pre-personalization of INLAY

[0053] 1. Produced by INLAY

[0054] A. Punching

[0055] Through the automatic punching machine (automatic positioning and identification mark cutting circular positioning hole) and full chip position hole punching (full plate direct punching, there is no step error of traditional punching, and the position of the hole is guaranteed during mold making Accuracy).

[0056] B. Winding

[0057] The dual-interface card has a non-contact function that involves the winding process. Using ultrasonic wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com