Protective film and preparation method thereof

A protective film and protective layer technology, applied in chemical instruments and methods, lamination, coating, etc., can solve the problems of poor adhesion, non-solvent resistance of PC surface, etc., and achieve good formability, high light transmittance, and improved The effect of visual experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

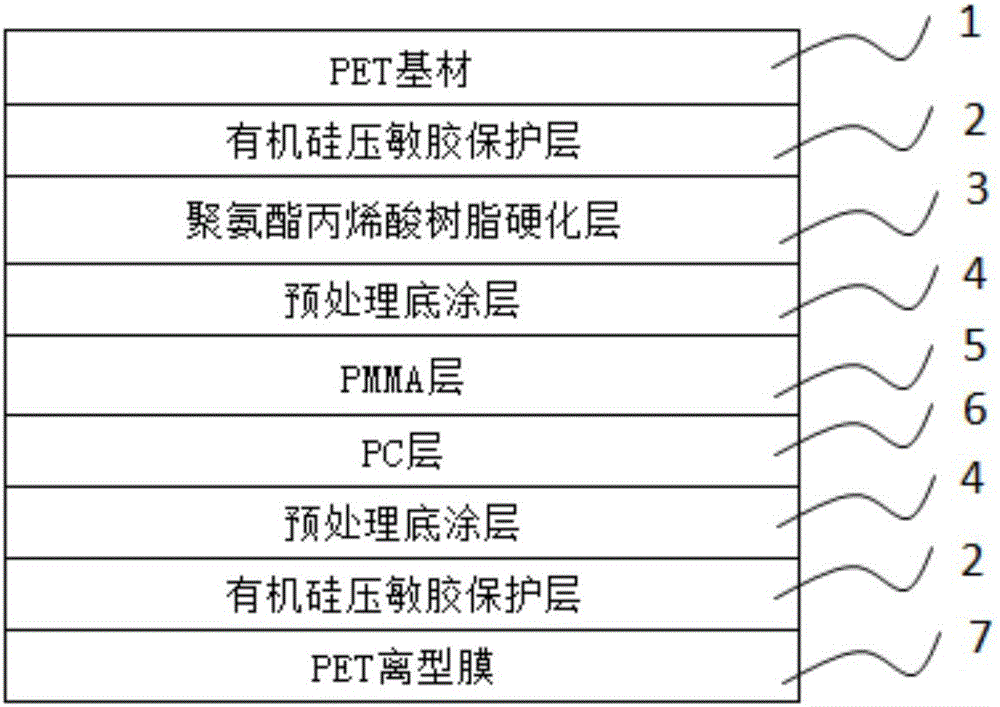

[0028] Such as figure 1 As shown, a 2.5D protective film, the protective film from top to bottom is PET substrate 1, silicone pressure-sensitive adhesive protective layer 2, polyurethane acrylic resin hardened layer 3, PMMA (polymethyl methacrylate) Layer 5, PC (polycarbonate) layer 6, silicone pressure-sensitive adhesive protective layer 2, PET release film 7, the contact surface of the PMMA layer 5 and the polyurethane acrylic resin hardening layer 4 is coated with pretreatment A primer layer 4 , a pretreatment primer layer 4 is coated on the contact surface between the PC layer 6 and the silicone pressure-sensitive adhesive protective layer 2 .

[0029] Specifically, the pretreatment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com