Method for preparing nano-pore structured polyethylene terephthalate (PET) foams by foaming through supercritical CO2

A CO2, supercritical technology, applied in the field of preparing PET foaming materials with nanoporous structure, can solve the problems of poor signal-to-noise ratio, affecting gas diffusion properties, reducing equilibrium solubility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

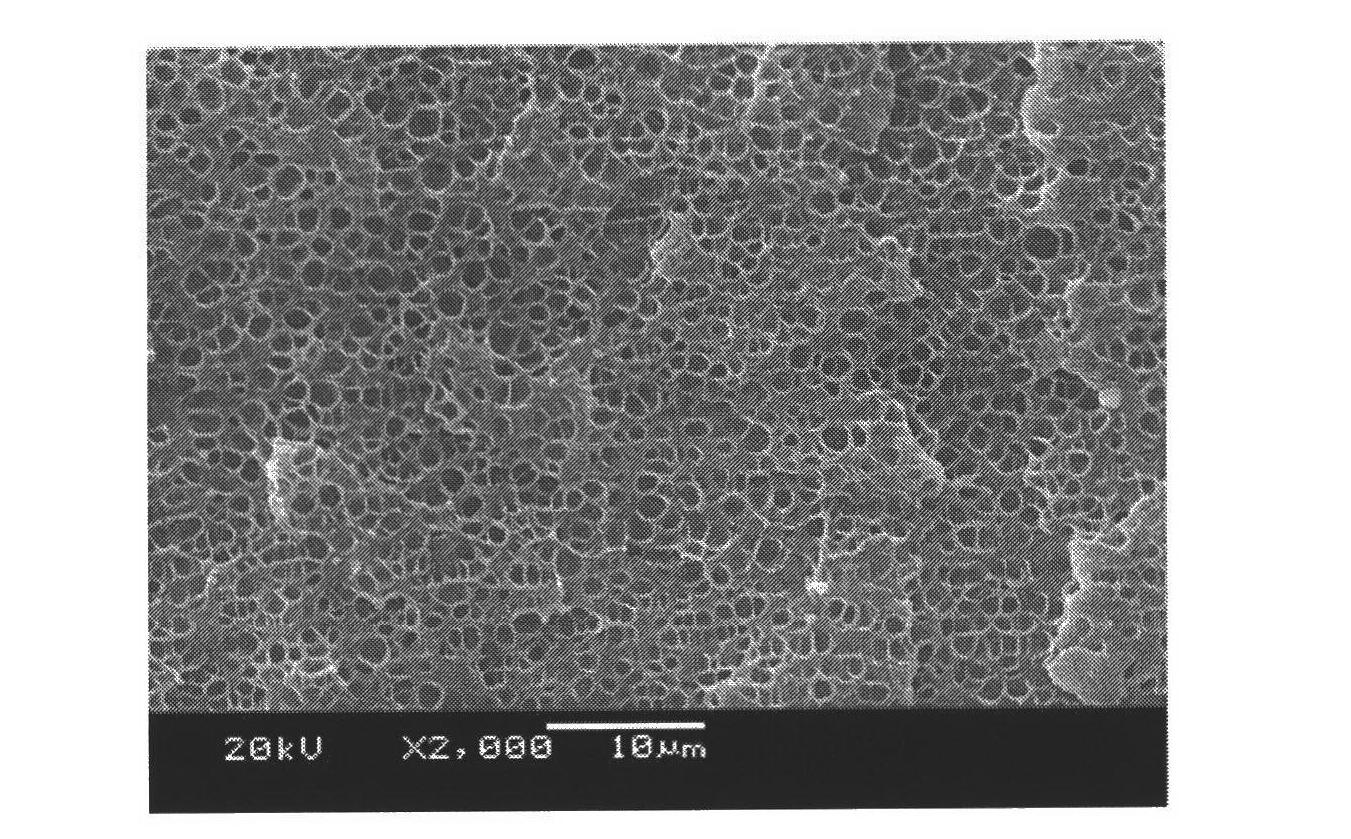

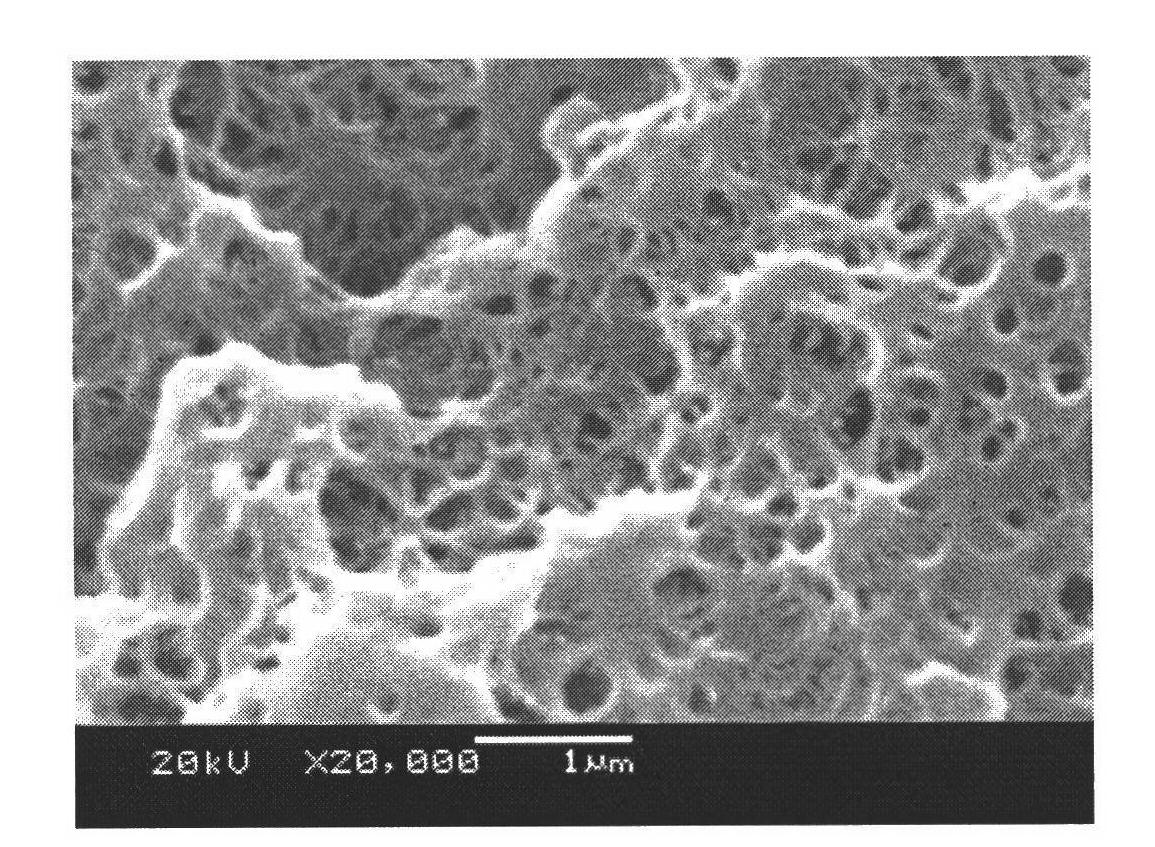

Embodiment 1

[0031] Firstly, the above-prepared amorphous PET sheet is placed in an autoclave, and after the autoclave is sealed, it is first purged with low-pressure carbon dioxide gas three to four times to remove air, and then filled with supercritical carbon dioxide gas. Then the autoclave was immersed in a constant temperature water bath with CO 2 Diffused slowly into the PET matrix. After 10 days, the CO 2 The gas is vented, the autoclave is quickly opened, the PET sheet is taken out and quickly immersed in a high temperature silicone oil bath. Due to the rapid increase in the temperature of the PET matrix, the CO 2 In which the solubility decreases rapidly, CO 2 It is precipitated in the form of gas, and at the same time, the molecular chain of PET already has strong movement ability at this temperature, and the two together induce the nucleation and growth of bubbles. After 10 seconds, the PET samples were immersed in an ice-water bath to fix the cell morphology. The sample wa...

Embodiment 2

[0033] Firstly, the above-prepared amorphous PET sheet is placed in an autoclave, and after the autoclave is sealed, it is first purged with low-pressure carbon dioxide gas three to four times to remove air, and then filled with supercritical carbon dioxide gas. Then the autoclave was immersed in a constant temperature water bath with CO 2 Diffused slowly into the PET matrix. After 15 days, the CO 2 The gas is vented, the autoclave is quickly opened, the PET sheet is taken out and quickly immersed in a high temperature silicone oil bath. Due to the rapid increase in the temperature of the PET matrix, the CO 2 In which the solubility decreases rapidly, CO 2 It is precipitated in the form of gas, and at the same time, the molecular chain of PET already has strong movement ability at this temperature, and the two together induce the nucleation and growth of bubbles. After 10 seconds, the PET samples were immersed in an ice-water bath to fix the cell morphology. The sample wa...

Embodiment 3

[0035] Firstly, the above-prepared amorphous PET sheet is placed in an autoclave, and after the autoclave is sealed, it is first purged with low-pressure carbon dioxide gas three to four times to remove air, and then filled with supercritical carbon dioxide gas. Then the autoclave was immersed in a constant temperature water bath with CO 2 Diffused slowly into the PET matrix. After 20 days, the CO 2 The gas is vented, the autoclave is quickly opened, the PET sheet is taken out and quickly immersed in a high temperature silicone oil bath. Due to the rapid increase in the temperature of the PET matrix, the CO 2 In which the solubility decreases rapidly, CO 2 It is precipitated in the form of gas, and at the same time, the molecular chain of PET already has strong movement ability at this temperature, and the two together induce the nucleation and growth of bubbles. After 10 seconds, the PET samples were immersed in an ice-water bath to fix the cell morphology. The sample wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com