Composite brightness enhancement film and backlight module

A technology of backlight module and brightness enhancement film, applied in the field of optical film, can solve the problems of high thickness of backlight module and complicated assembly process, and achieve the effect of low thickness, good uniformity and reduced thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

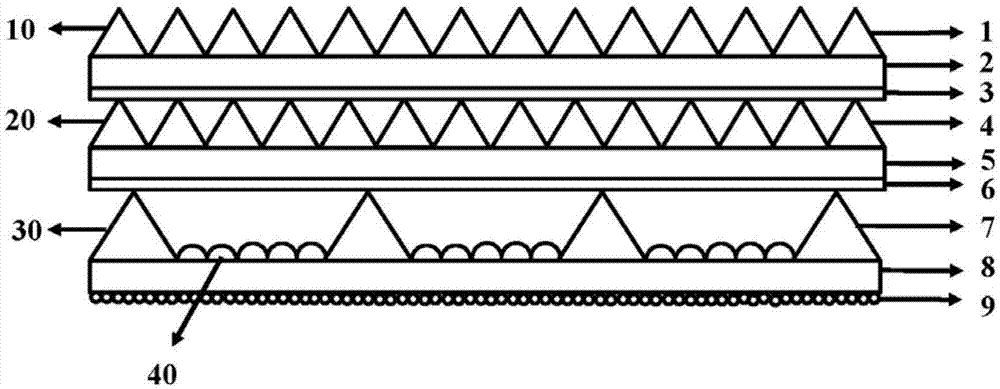

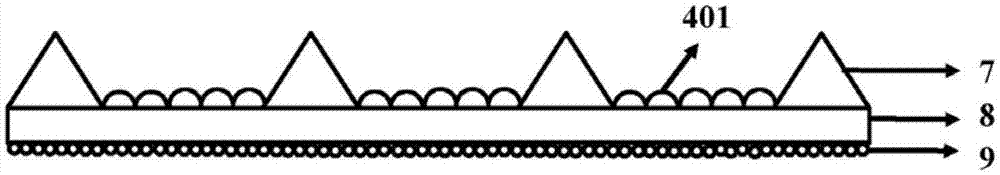

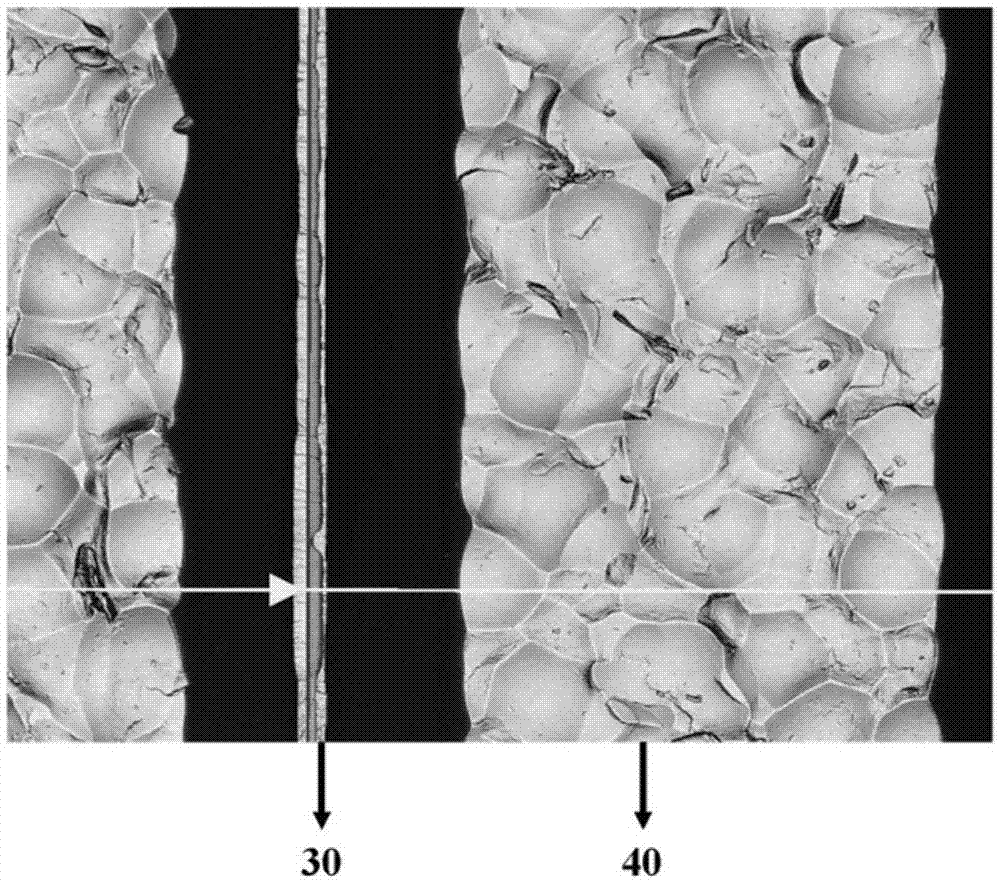

[0052] In the composite brightness enhancing film provided by the present invention, the composite film sequentially includes a first prism film, a first adhesive layer, a second prism film, a second adhesive layer, and a third prism film; the first prism film includes a first A prism layer and a first PET substrate layer; the second prism film comprises a second prism layer and a second PET substrate layer; the third prism film comprises a third prism layer, a third PET substrate layer and a backcoat; The first PET substrate layer is bonded together with the second prism layer through the first bonding layer, and the second PET substrate layer is bonded together with the third prism layer through the second bonding layer; A prism layer is made up of some first prism bars; the second prism layer is made up of some second prism bars; the third prism layer is made up of some third prism bars and some diffusion areas, and the third prism bars and the diffusion areas alternate arr...

Embodiment 2

[0061] Composite brightness enhancing film as provided in embodiment 1, wherein,

[0062] The thickness of the first PET substrate layer is 50 μm, the thickness of the second PET substrate layer is 50 μm, the thickness of the third PET substrate layer is 50 μm, and the thickness of the back coating is 15-18 μm.

[0063] The prism width of the first prism bar and the second prism bar is 44 μm.

[0064] The prism width of the third prism bar was 75 μm. The width of the diffusion region was 200 μm.

[0065] The protruding structure is a circular protruding structure, the diameter of the circular protruding structure is 5-40 μm, and the height is 1-6 μm.

[0066] The content of the adhesive in the back coat is 85%, and the content of PMMA and PBMA is 7.5%, respectively. The particle size of the organic particles is 600nm-900nm.

Embodiment 3

[0068] Composite brightness enhancing film as provided in embodiment 1, wherein,

[0069] The thickness of the first PET substrate layer is 50 μm, the thickness of the second PET substrate layer is 50 μm, the thickness of the third PET substrate layer is 50 μm, and the thickness of the back coating is 15-18 μm.

[0070] The prism width of the first prism strip and the second prism strip is 50 μm.

[0071] The prism width of the third prism bar was 75 μm, and the width of the diffusion region was 200 μm.

[0072] The protruding structure is a circular protruding structure, the diameter of the circular protruding structure is 5-10 μm, and the height is 1-6 μm.

[0073] The content of the adhesive in the back coat is 85%, and the content of PMMA and PBMA is 7.5%, respectively.

[0074] The particle size of the organic particles is 1 μm-10 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com