Hardened protective film and production method thereof

A technology of protective film and hardened layer, which is applied in the direction of chemical instruments and methods, layered products, and synthetic resin layered products, etc. Effects and other problems, to achieve excellent resistance, reduce the difficulty of film sticking, and low bubble generation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

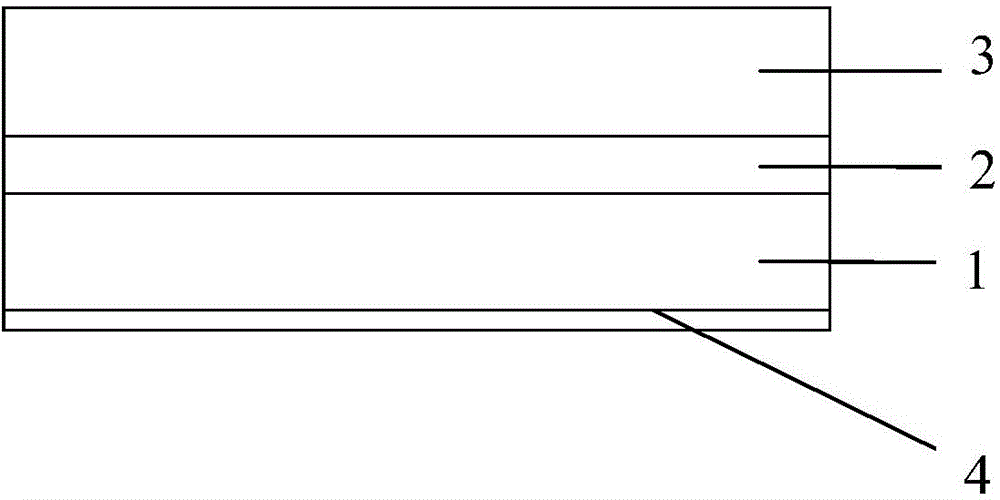

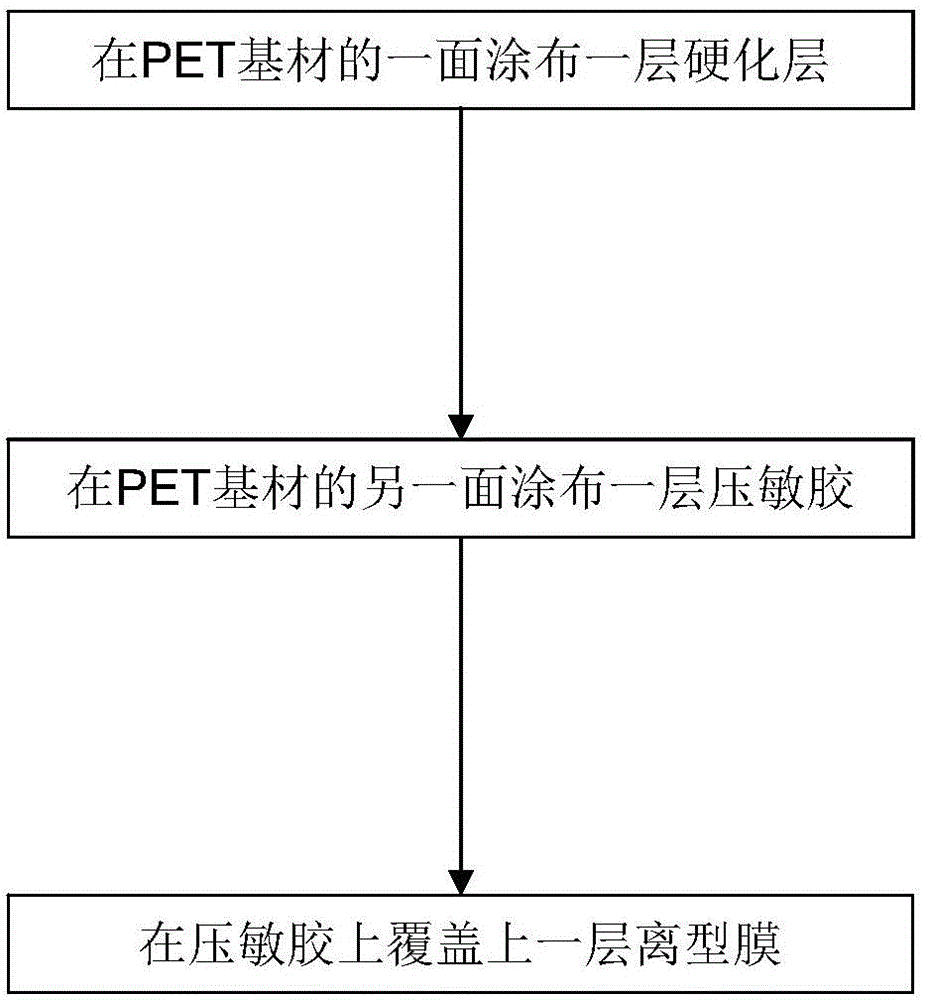

Embodiment 1

[0040] Add 20g of hexafunctional aliphatic urethane acrylate, 5g of ethoxylated pentaerythritol tetraacrylate, 1g of benzophenone and 0.5g of smoothing agent into 63.5g of butyl acetate, stir and mix uniformly to prepare a hardening solution; use a 12μm wire The bar coater coats the hardening liquid on one surface of the PET substrate 1, and then it is dried in a dryer at 80°C for 1 min, and then cured by ultraviolet light (the irradiating brightness of ultraviolet light is 600mj / cm 2 ), the semi-finished hardened protective film coated with the hardened layer 4 is prepared.

[0041] Add 20g of aromatic isocyanate, 2g of polyester polyol curing agent and 0.2g of conductive agent to 40g of ethyl acetate, stir and mix uniformly to prepare a pressure-sensitive adhesive; apply the pressure-sensitive adhesive with a 45μm wire rod applicator Cover the other side of the PET substrate 1 coated with the hardened layer, and dry it in a dryer at 80°C for 1 min. After leaving the oven, cover ...

Embodiment 2

[0043] Add 20g of hexafunctional aliphatic urethane acrylate, 7g of ethoxylated pentaerythritol tetraacrylate, 1.2g of benzophenone and 0.3g of smoothing agent to 50g of butyl acetate, stir and mix uniformly to prepare a hardening solution; use a 12μm wire The bar coater coats the hardening liquid on one surface of the PET substrate 1, and then it is dried in a dryer at 80°C for 1 min, and then cured by ultraviolet light (the irradiating brightness of ultraviolet light is 600mj / cm 2 ), the hardened protective film semi-finished product coated with the hardened layer 4 is prepared.

[0044] Add 20g of aromatic isocyanate, 2g of polyester polyol curing agent and 0.2g of conductive agent to 40g of ethyl acetate, stir and mix uniformly to prepare a pressure-sensitive adhesive; apply the pressure-sensitive adhesive with a 45μm wire rod applicator Coated on the other side of the PET substrate 1 with the hardened layer, dried in a dryer at 80°C for 1 min, after leaving the oven, the rele...

Embodiment 3

[0046] Add 20g of hexafunctional aliphatic urethane acrylate, 5g of ethoxylated pentaerythritol tetraacrylate, 1g of benzophenone and 0.5g of smoothing agent into 63.5g of butyl acetate, stir and mix uniformly to prepare a hardening solution; use a 12μm wire The bar coater coats the hardening liquid on one surface of the PET substrate 1, and then it is dried in a dryer at 80°C for 1 min, and then cured by ultraviolet light (the irradiating brightness of ultraviolet light is 600mj / cm 2 ), the hardened protective film semi-finished product coated with the hardened layer 4 is prepared.

[0047] Add 20g of aromatic isocyanate, 3g of polyester polyol curing agent and 0.5g of conductive agent to 30g of ethyl acetate, stir and mix uniformly to prepare a pressure-sensitive adhesive; use a 45μm wire rod applicator to coat the pressure-sensitive adhesive Coated on the other side of the PET substrate 1 with the hardened layer, dried in a dryer at 80°C for 1 min, after leaving the oven, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com