RFID printed antenna hot stamped electronic tag and manufacturing method thereof

A technology for printing antennas and electronic labels, which is applied to record carriers, instruments, and computer parts used in machines. It can solve problems such as inability to meet customer needs, and achieve the effect of avoiding a large number of imitations, stable performance, and increasing aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

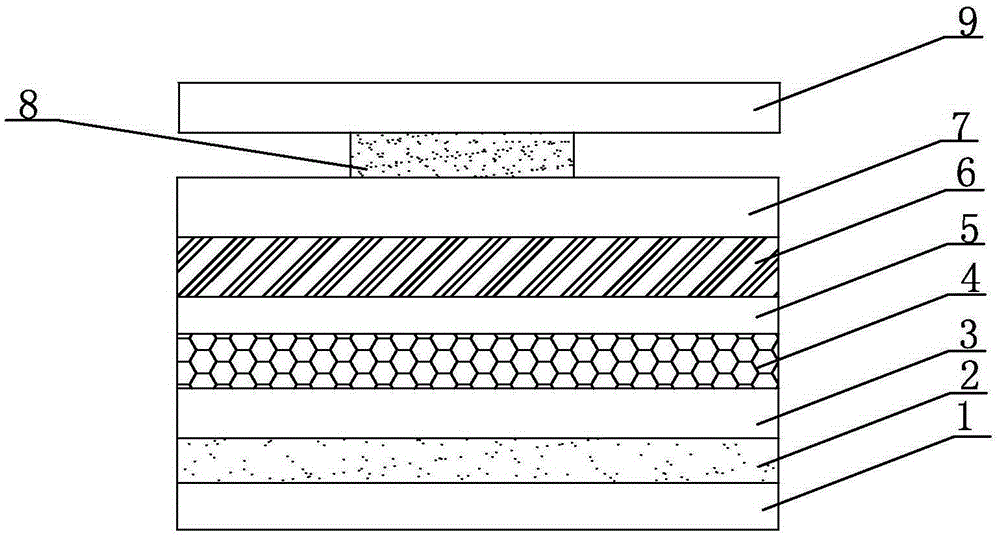

[0054] An RFID printing antenna hot stamping electronic label, such as figure 1 As shown, a PET substrate layer 1 is included, and a release layer 2, an information layer 3, a printing layer 4, a first adhesive layer 5, an antenna substrate layer 6, and a printed antenna layer 7 are sequentially arranged on the PET substrate layer 1 from bottom to top. The chip 8 is packaged upside down on the printed antenna layer 7 , and the second glue layer 9 is arranged on the chip 8 .

[0055] A method for preparing an RFID printing antenna hot stamping electronic label, comprising the following steps:

[0056] 1. Select a 30um base material PET to coat the release layer, and use a coating machine to coat the release layer and the information layer (color layer) on it. The release layer coating solution is coated with 4 cups and has a viscosity of 20s. After testing, the release layer The thickness of the type layer is 1.5um, and the 180-degree peel strength of the release layer is 0.00...

Embodiment 2

[0066] An RFID printing antenna hot stamping electronic label, such as figure 1 As shown, a PET substrate layer 1 is included, and a release layer 2, an information layer 3, a printing layer 4, a first adhesive layer 5, an antenna substrate layer 6, and a printed antenna layer 7 are sequentially arranged on the PET substrate layer 1 from bottom to top. The chip 8 is packaged upside down on the printed antenna layer 7 , and the second glue layer 9 is arranged on the chip 8 .

[0067] A method for preparing an RFID printing antenna hot stamping electronic label, comprising the following steps:

[0068] 1. Select a 50um double-sided corona-free substrate PET to coat the release layer, and use a coating machine to coat the release layer and the information layer (color layer) on it. The release layer coating liquid is coated with 4 cups of viscosity. 22s, the thickness of the release layer is 2.1um, and the 180-degree peel strength of the release layer is 0.002KN / m;

[0069] 2. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com