Preparation method of wearable transparent flexible film type strain sensor

A technology of strain sensor and flexible film, which is applied in the measurement of the property force of piezoelectric resistance materials, the manufacture of microstructure devices, and the technology for producing decorative surface effects, etc. It can solve the problem of complex device structure, poor concealment, and high cost. problems, achieve the effect of low conductive seepage threshold, excellent conductivity, and good concealment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

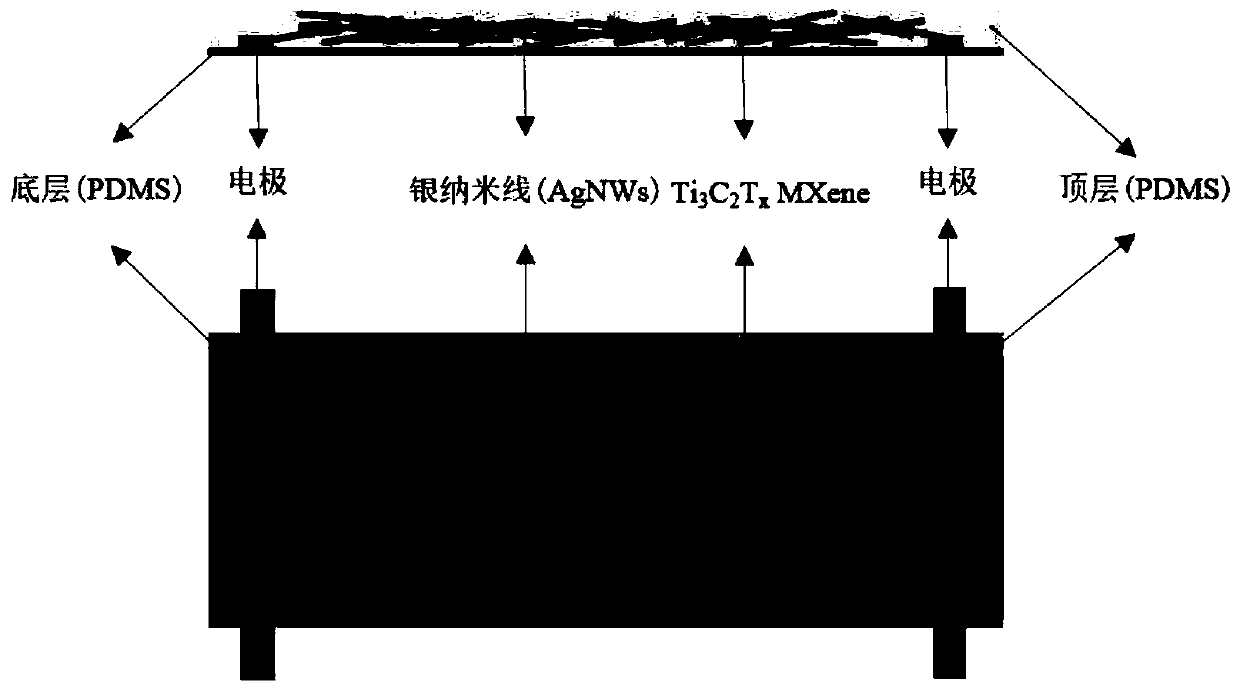

[0022] a. Dilute the AgNWs dispersion with a concentration of 10mg / mL to 1.0mg / mL and stir until uniform;

[0023] b. Ultrasonic cleaning the polyethylene terephthalate (PET) substrate with deionized water, ethanol and isopropanol for 10 minutes respectively, and drying with an argon gun;

[0024] c. Spin-coat polydimethylsiloxane (PDMS) on the cleaned PET substrate, and cure at 60°C for 120 minutes;

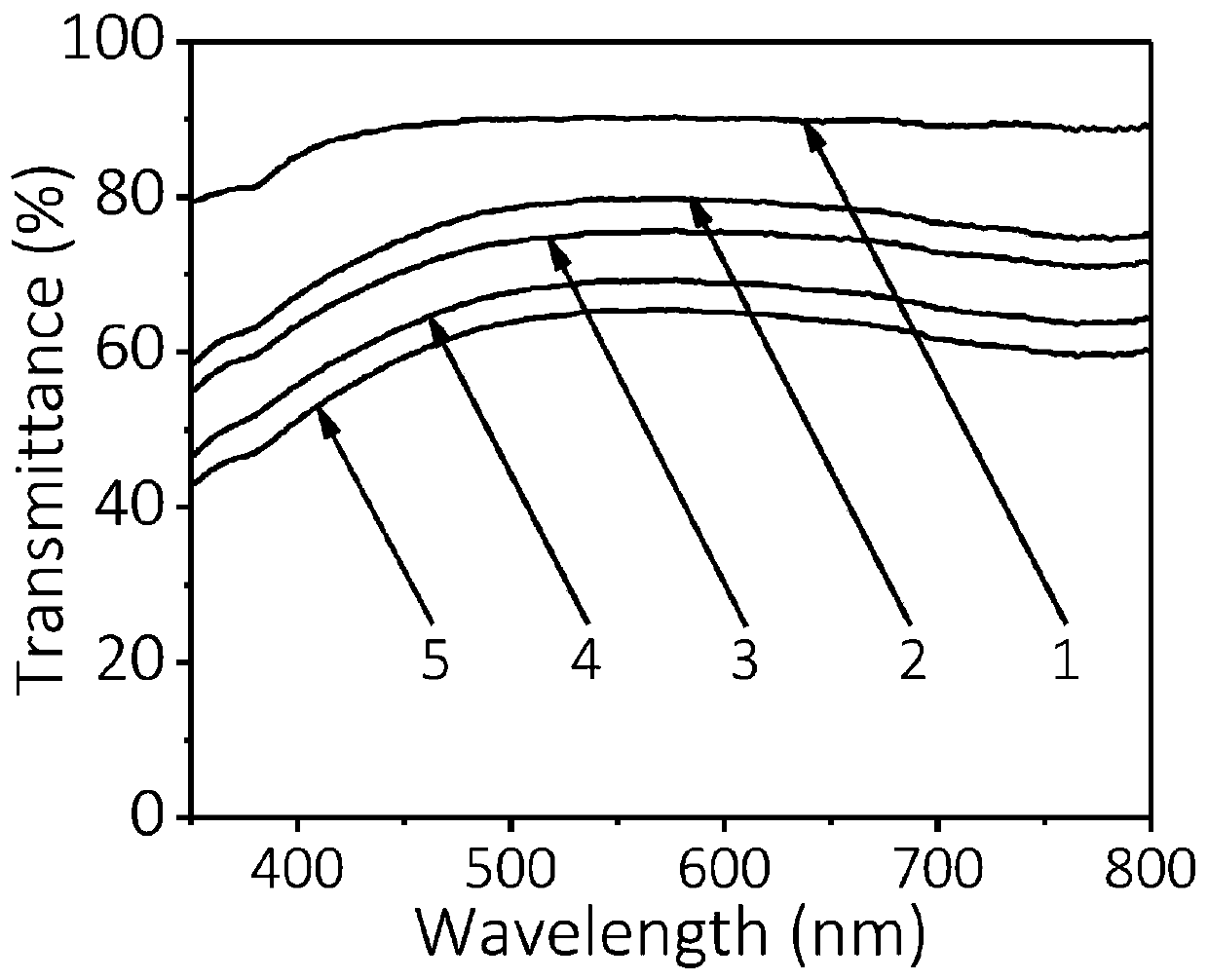

[0025] d. Add 1.0mg / mL Ti 3 C 2 T x The MXene dispersion was sprayed onto the surface of the PDMS film (the spraying time was 5s), and then dried at 65°C;

[0026] e. Then spray 1.0 mg / mL AgNWs dispersion on the surface of PDMS film, and then dry at 65 °C;

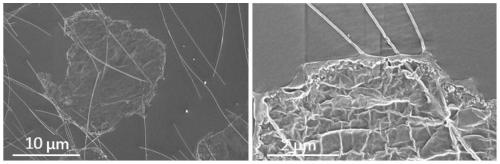

[0027] f. The dried sample was peeled off from the PET substrate to obtain AgNWs / Ti 3 C 2 T x MXene-based transparent flexible conductive film;

[0028] g. On AgNWs / Ti 3 C 2 T x The two ends of the MXene-based transparent flexible conductive film are made of metal electrodes (such as magnetron sputtering silver...

Embodiment 2

[0031] a. Dilute the AgNWs dispersion with a concentration of 10mg / mL to 2.0mg / mL and stir until uniform;

[0032] b. Ultrasonic clean the PET substrate with deionized water, ethanol and isopropanol for 10 minutes, and dry it with an argon gun;

[0033] c. Spin-coat PDMS onto the cleaned PET substrate and cure at 65°C for 100 minutes;

[0034] d. Add 1.25mg / mL Ti 3 C 2 T xThe MXene dispersion was sprayed onto the surface of the PDMS film (the spraying time was 10s), and then dried at 70°C;

[0035] e. Spin-coat the 2.0 mg / mL AgNWs dispersion on the surface of the PDMS film, and then dry it at 70 °C;

[0036] f. The dried sample was peeled off from the PET substrate to obtain AgNWs / Ti 3 C 2 T x MXene-based transparent flexible conductive film;

[0037] g in AgNWs / Ti 3 C 2 T x Metal electrodes (such as magnetron sputtering silver electrode method, thermal evaporation silver electrode method, drop-coating conductive polymer method, pasting copper tape method, smearin...

Embodiment 3

[0040] a. Dilute the AgNWs dispersion with a concentration of 10mg / mL to 3.0mg / mL and stir until uniform;

[0041] b. Ultrasonic clean the PET substrate with deionized water, ethanol and isopropanol for 10 minutes, and dry it with an argon gun;

[0042] c. Spin-coat PDMS onto the cleaned PET substrate and cure at 70°C for 80 minutes;

[0043] d. Add 1.5mg / mL Ti 3 C 2 T x The MXene dispersion was sprayed onto the surface of the PDMS film (spraying time was 15s), and then dried at 75°C;

[0044] e. Spin-coat the 3.0 mg / mL AgNWs dispersion on the surface of the PDMS film, and then dry it at 75 °C;

[0045] f. The dried sample was peeled off from the PET substrate to obtain AgNWs / Ti 3 C 2 T x MXene-based transparent flexible conductive film;

[0046] g. On AgNWs / Ti 3 C 2 T x Metal electrodes (such as magnetron sputtering silver electrode method, thermal evaporation silver electrode method, drop-coating conductive polymer method, pasting copper tape method, smearing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com