Flexible integrated ultrasonic transducer and preparation method thereof

An ultrasonic transducer and flexible technology, applied in the directions of sound-producing equipment, semiconductor/solid-state device manufacturing, instruments, etc., can solve the problems of low gain and low signal-to-noise ratio, and achieve the effect of improving sensitivity, reducing manufacturing cost and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

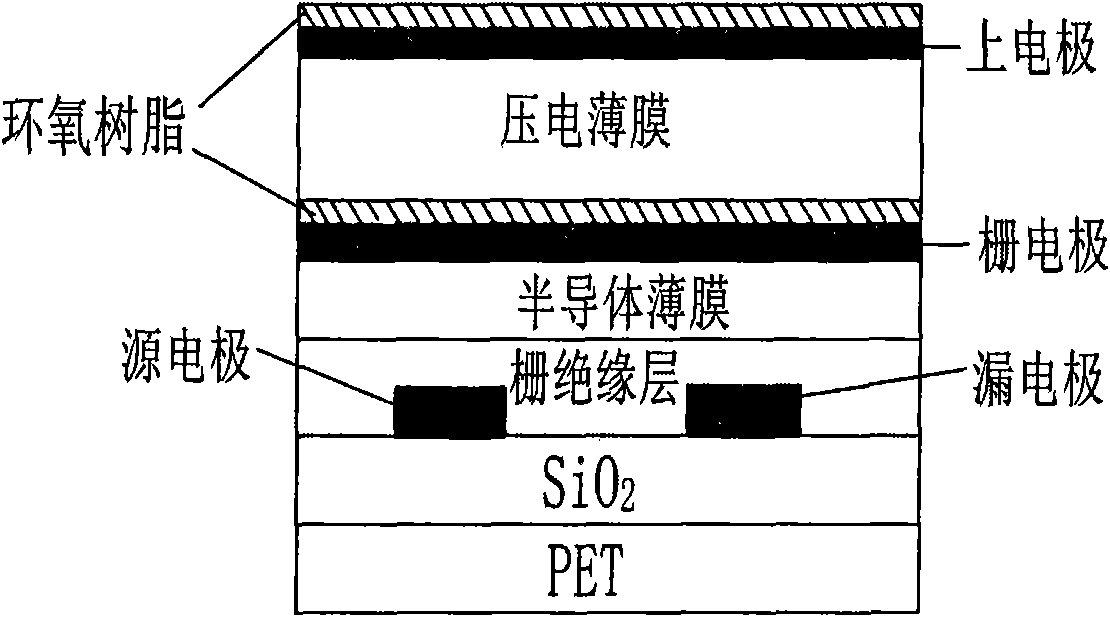

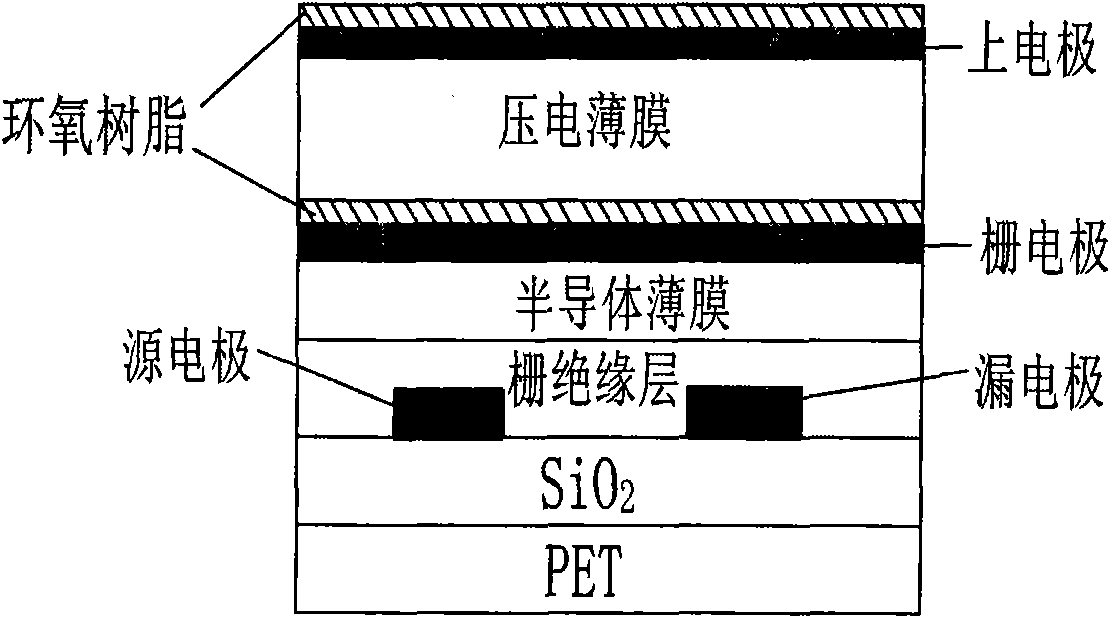

[0026] The flexible integrated ultrasonic transducer of the present invention is structurally integrated with an organic thin film transistor and a piezoelectric sensor. Substrate 1, silicon dioxide isolation layer 2, source and drain electrodes 3, organic semiconductor film layer 4, gate dielectric layer 5, gate electrode layer 601, epoxy resin film layer 701, polyvinylidene fluoride PVDF piezoelectric film layer 8 , upper electrode layer 602 and epoxy resin film layer 702.

[0027] The preparation method of the flexible integrated ultrasonic transducer of the present invention is carried out according to the following steps:

[0028] (1) Preparation of moisture-proof isolation layer: Magnetron sputtering can be used to deposit silicon dioxide (SiO2) on a flexible substrate of polyethylene terephthalate (PET). 2 )film;

[0029] (2) preparation of an organic thin film transistor, the steps of which include:

[0030] Step 1: Depositing a metal thin film layer on the substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com