Solar battery package material and solar battery

A solar cell and packaging material technology, applied in the field of solar cells, can solve the problems of reduced service life of solar cells, low reflectivity of solar cells, and high cost of fluorine-containing resin films, and achieve the effects of preventing degradation, reducing costs, and improving reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

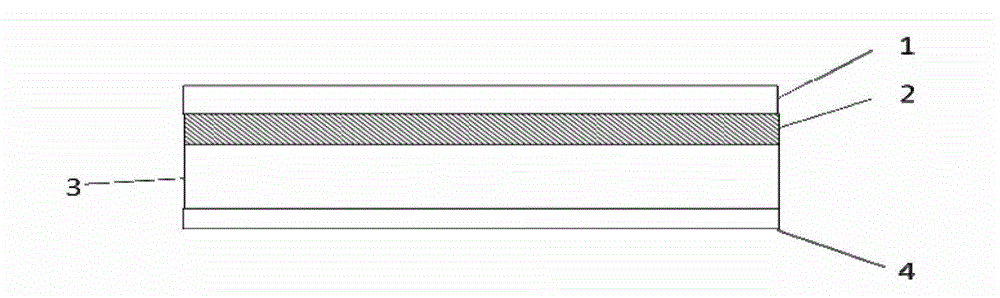

Image

Examples

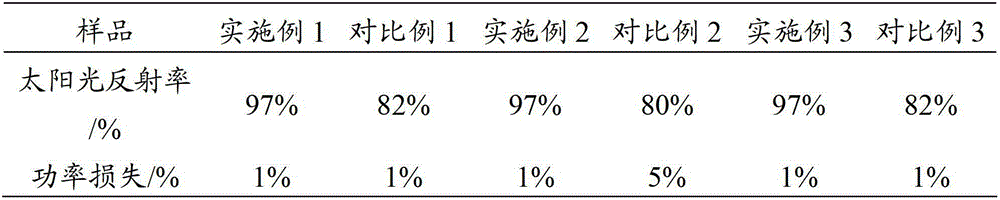

Embodiment 1

[0053] 100 parts by mass of EVA resin of Elvax150 produced by DuPont Company, 0.3 parts by mass of Tinuvin 770 produced by Ciba Company as UV stabilizer, 0.2 parts by mass of Naugard P produced by Uniroyal Company as antioxidant, 1.5 parts by mass of Lupersol1101 produced by Pennwalt Company As a cross-linking agent, it was mixed with 15 parts by mass of titanium dioxide of the type R-960 produced by Dupont Company to obtain a white EVA film, and the thickness of the white EVA film was 15 μm;

[0054] 100 parts by mass of EVA resin of Elvax150 produced by DuPont Company, 0.3 parts by mass of Tinuvin 770 produced by Ciba Company as UV stabilizer, 0.2 parts by mass of Naugard P produced by Uniroyal Company as antioxidant and 1.5 parts by mass of Lupersol1101 produced by Pennwalt Company Mixed as a cross-linking agent to obtain a transparent EVA film, the thickness of the transparent EVA film is 60 μm;

[0055]The transparent EVA film and the white EVA film are subjected to doubl...

Embodiment 2

[0064] 100 parts by mass of EVA resin with a melt index (190 ° C, 2.16 kg) produced by Samsung Total Petrochemical Company of 10 g / min and a vinyl acetate content of 28%, and 0.3 parts by mass of Chimassorb81 produced by Ciba Company as an ultraviolet stabilizer, 0.2 Parts by mass of di(octadecyl)thiodipropionate are used as an antioxidant, 1.5 parts by mass of Luperox TBEC produced by ARKEMA Company as a crosslinking agent and 15 parts by mass of titanium dioxide produced by Dupont Company as R-105 are mixed to prepare Obtain white EVA film, the thickness of white EVA film is 15 μ m;

[0065] 100 parts by mass of EVA resin with a melt index (190 °C, 2.16 kg) produced by Samsung Total Petrochemical Company of 10 g / min and a vinyl acetate content of 28%, 0.3 parts by mass of Chimassorb81 produced by Ciba Company as an ultraviolet stabilizer, 0.2 Parts by mass of di(octadecyl)thiodipropionate were mixed as an antioxidant and 1.5 parts by mass of Luperox TBEC produced by ARKEMA C...

Embodiment 3

[0075] The model that 100 mass parts DuPont companies produce is the EVA resin of Elvax150, the Tinuvin770 that 0.3 mass parts Ciba companies produce as ultraviolet stabilizer, the Naugard P that 0.2 mass parts Uniroyal companies produce as antioxidant, the Lupersol1101 that 1.5 mass parts Pennwalt companies produce As a cross-linking agent and 15 parts by mass of titanium dioxide produced by Dupont, the model is mixed with R-960 to prepare a white EVA film, and the thickness of the white EVA film is 15 μm;

[0076] The model that 100 mass parts DuPont companies produce is the EVA resin of Elvax150, the Tinuvin770 that 0.3 mass parts Ciba companies produce as ultraviolet stabilizer, the Naugard P that 0.2 mass parts Uniroyal companies produce as antioxidant and the Lupersol1101 that 1.5 mass parts Pennwalt companies produce Mixed as a cross-linking agent to obtain a transparent EVA film, the thickness of the transparent EVA film is 60 μm;

[0077] The transparent EVA film and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com