Micronano-structure carbon silicon composite microsphere and preparation method and application thereof

A technology of structured carbon and composite microspheres, applied in structural parts, nanotechnology, nanotechnology, etc., can solve problems such as environmental pollution, cumbersome process, and harsh conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

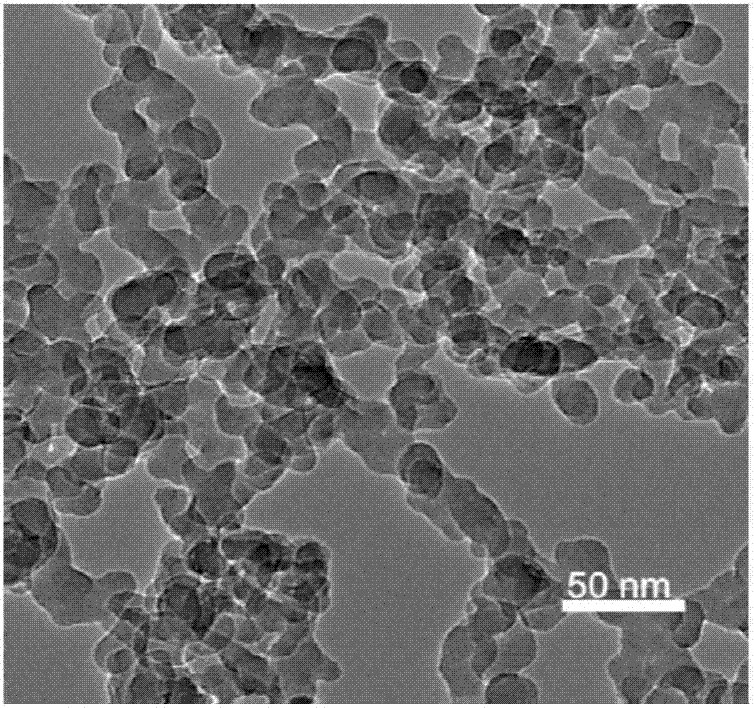

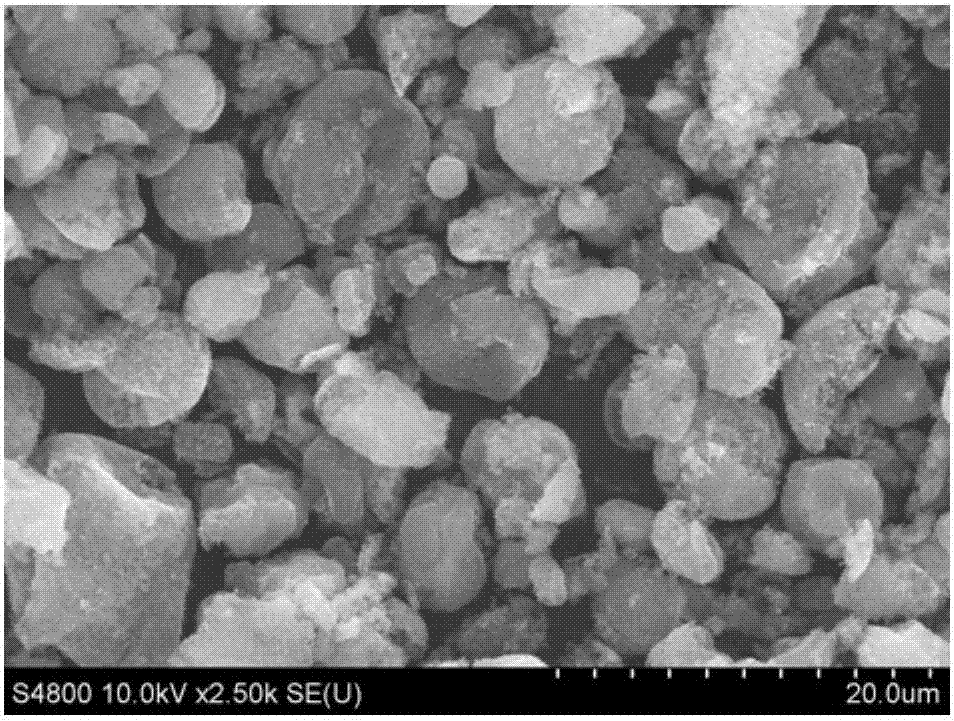

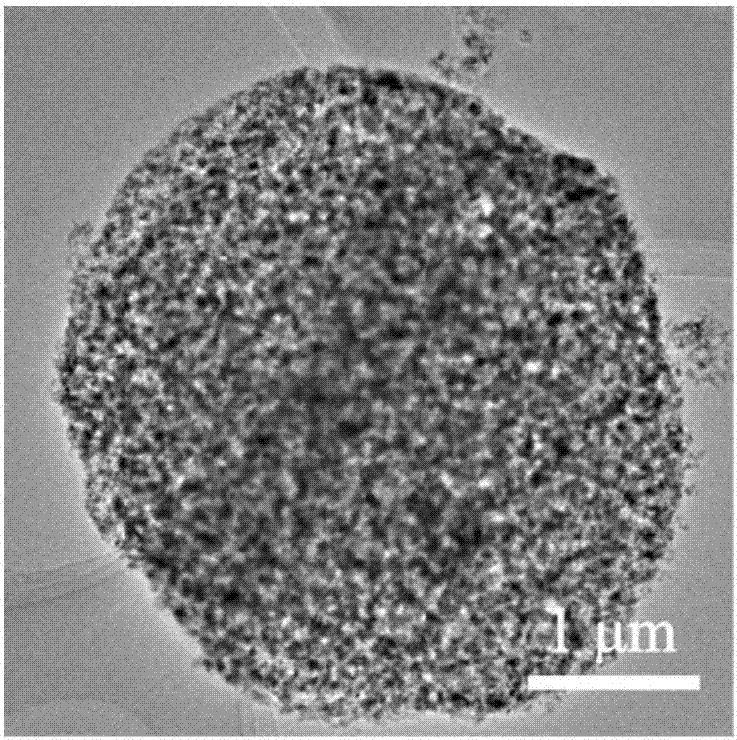

[0067]20nm silicon dioxide (such as figure 1 Shown) and glucose aqueous solution are mixed, as the precursor solution of spray drying; In this precursor solution, solute concentration is 15wt%; During spray drying, feed rate is 10mL / min, and air inlet temperature is 150 ℃, and air outlet The temperature was 80°C, and the carrier gas was air; the obtained powder was heat-treated under hydrogen at 500°C for 2 hours to obtain micronano structured carbon-silicon dioxide composite microspheres; magnesium was used as the reducing agent (the mass ratio of the obtained powder to the mass of the reducing agent Ratio 1:1), the prepared micronanostructured carbon-silica composite microspheres were reduced in a mixed atmosphere of hydrogen and argon at 650°C for 2h, and treated with 3 mol / L HCl to obtain micronanostructured carbon silicon Composite microspheres, the particle size of the prepared micro-nano structured carbon-silicon composite microspheres is 1-5 μm, the results are as foll...

Embodiment 2

[0070] A solution of 5nm silicon dioxide and polystyrene in dichloroethane was mixed as a spray-dried precursor solution; the solute concentration in the precursor solution was 0.1 wt%. During spray drying, the feed rate is 0.5mL / min, the inlet air temperature is 100°C, the outlet air temperature is 70°C, and the carrier gas is air. The obtained powder was heat-treated under argon at 900°C for 30 minutes to obtain micronano structured carbon-silicon dioxide composite microspheres; magnesium was used as a reducing agent (the mass ratio of the obtained powder to the reducing agent was 1:0.6), and the obtained Micronanostructured carbon-silicon dioxide composite microspheres were reduced in a mixed atmosphere of hydrogen and argon at 800°C for 0.5h, and treated with 4 mol / L sulfuric acid to obtain micronanostructured carbon silicon Composite microspheres; the particle size of the prepared micro-nano structured carbon-silicon composite microspheres is 0.5-2 μm; wherein, the weight...

Embodiment 3

[0073] An aqueous solution of 100 nm silicon dioxide particles, carbon nanotubes and starch was mixed as a spray-dried precursor solution; in the precursor solution, the solute concentration was 60 wt%. During spray drying, the feed rate was 95mL / min, the inlet air temperature was 220°C, the outlet air temperature was 100°C, and the carrier gas was argon. The obtained powder was heat-treated at 700°C for 6 h under nitrogen to obtain micronano structured carbon-silicon dioxide composite microspheres; using potassium as the reducing agent (the mass ratio of the obtained powder to the reducing agent was 1:3), the obtained micronanostructured carbon-silica composite microspheres were Nanostructured carbon-silicon dioxide composite microspheres were reduced in a mixed atmosphere of hydrogen and argon at 100°C for 48 hours, and the obtained composite microspheres were treated with 3 mol / L HCl to obtain micro-nano structured carbon-silicon composite microspheres; The particle size of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com