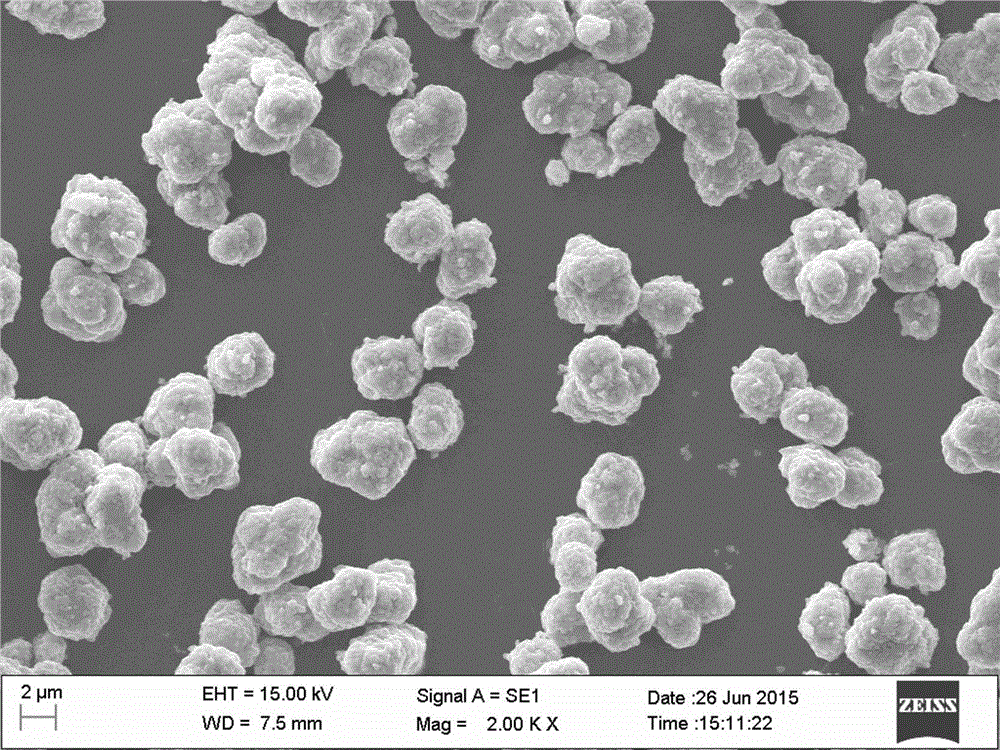

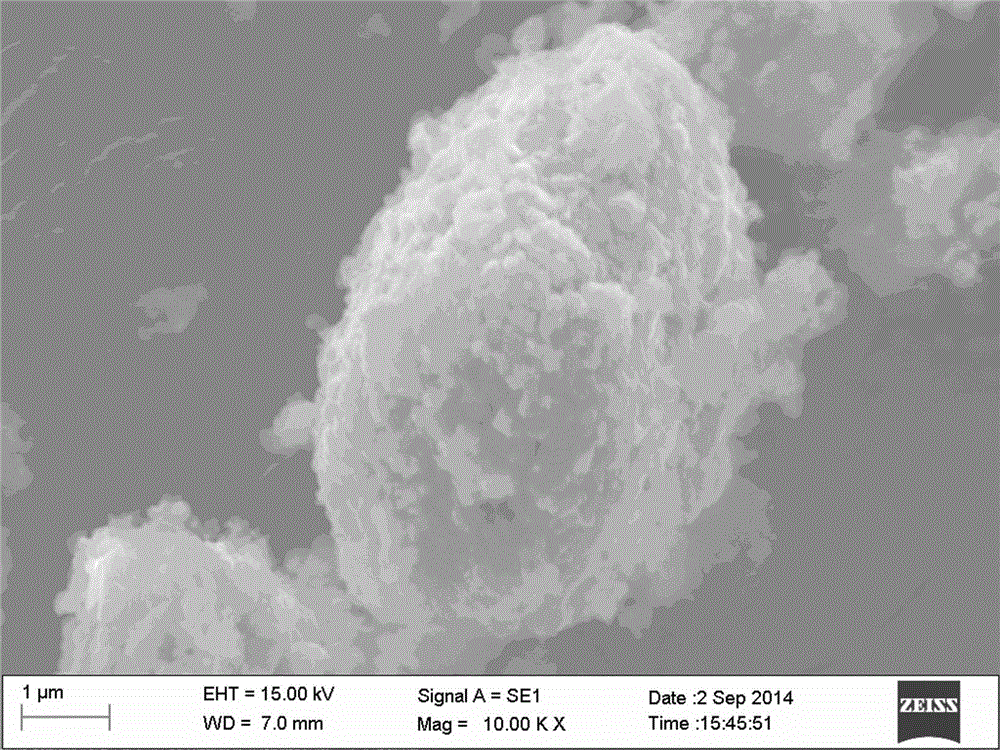

Preparation method of LiFePO4/C modified ternary positive electrode material

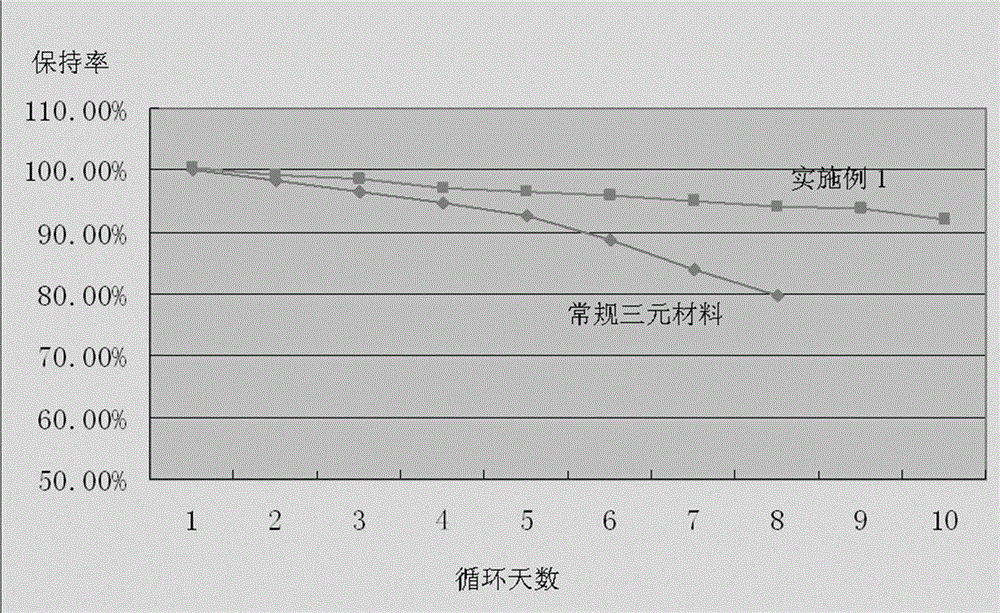

A positive electrode material and modification technology, which is applied in the field of electrochemical material preparation, can solve problems such as cycle performance deterioration, battery capacity loss, and material electrochemical performance deterioration, and achieve high-rate discharge performance, capacity density, and contact area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Preparation of ternary cathode material precursor by co-precipitation method:

[0022] Prepare a mixed aqueous solution of nickel, cobalt and manganese, with a total concentration of 2.0mol / L, in which the molar ratio of the three metal salts is Ni:Co:Mn=1:1:1; prepare sodium hydroxide to 2.0mol / L, and prepare ammonia water The concentration is 2.0mol / L, the mixed salt solution, sodium hydroxide solution and ammonia water are flowed into the reaction kettle with a certain bottom liquid by three metering pumps respectively, and the flow rate of the mixed salt solution, precipitant and complexing agent is adjusted to make the reaction The pH value in the kettle was 10.5, the temperature in the reaction kettle was controlled at 35°C, and the dropping time was controlled at 15 hours. Finally, the reaction materials were washed and dried to obtain a spherical precursor with a particle size of 6 μm.

[0023] (2) Preparation of ternary cathode material:

[0024] Lithium c...

Embodiment 2

[0029] (1) Preparation of ternary cathode material precursor by co-precipitation method:

[0030] Prepare a mixed aqueous solution of nickel, cobalt and manganese, with a total concentration of 4.0mol / L, in which the molar ratio of the three metal salts is Ni:Co:Mn=0.8:0.1:0.1; prepare sodium hydroxide to 2.0mol / L, and prepare ammonia water The concentration is 2.0mol / L, the mixed salt solution, sodium hydroxide solution and ammonia water are flowed into the reaction kettle with a certain bottom liquid by three metering pumps respectively, and the flow rate of the mixed salt solution, precipitant and complexing agent is adjusted to make the reaction The pH value in the kettle was 12, the temperature in the reaction kettle was controlled at 35°C, and the dropping time was controlled at 15 hours. Finally, the reaction materials were washed and dried to obtain a spherical precursor with a particle size of 4 μm.

[0031] (2) Preparation of ternary cathode material:

[0032] Lithi...

Embodiment 3

[0037] (1) Preparation of ternary cathode material precursor by co-precipitation method:

[0038] Prepare a mixed aqueous solution of nickel, cobalt and manganese, with a total concentration of 2.0mol / L, wherein the molar ratio of the three metal salts is Ni:Co:Al=0.8:0.1:0.1; prepare sodium hydroxide to 2.0mol / L, and prepare ammonia water The concentration is 2.0mol / L, the mixed salt solution, sodium hydroxide solution and ammonia water are flowed into the reaction kettle with a certain bottom liquid by three metering pumps respectively, and the flow rate of the mixed salt solution, precipitant and complexing agent is adjusted to make the reaction The pH value in the kettle was 11.5, the temperature in the reaction kettle was controlled at 35°C, and the dropping time was controlled at 15 hours. Finally, the reaction materials were washed and dried to obtain a spherical precursor with a particle size of 8 μm.

[0039] (2) Preparation of ternary cathode material:

[0040] Lith...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com