Method for preparing ultracapacitor-used porous grapheme material

A porous graphene and supercapacitor technology, applied in the field of preparing porous graphene materials for supercapacitors, can solve the problems of low graphitization degree, complicated preparation process, and large environmental pollution of ordinary porous carbon materials, and achieve easy removal and abundant sources , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

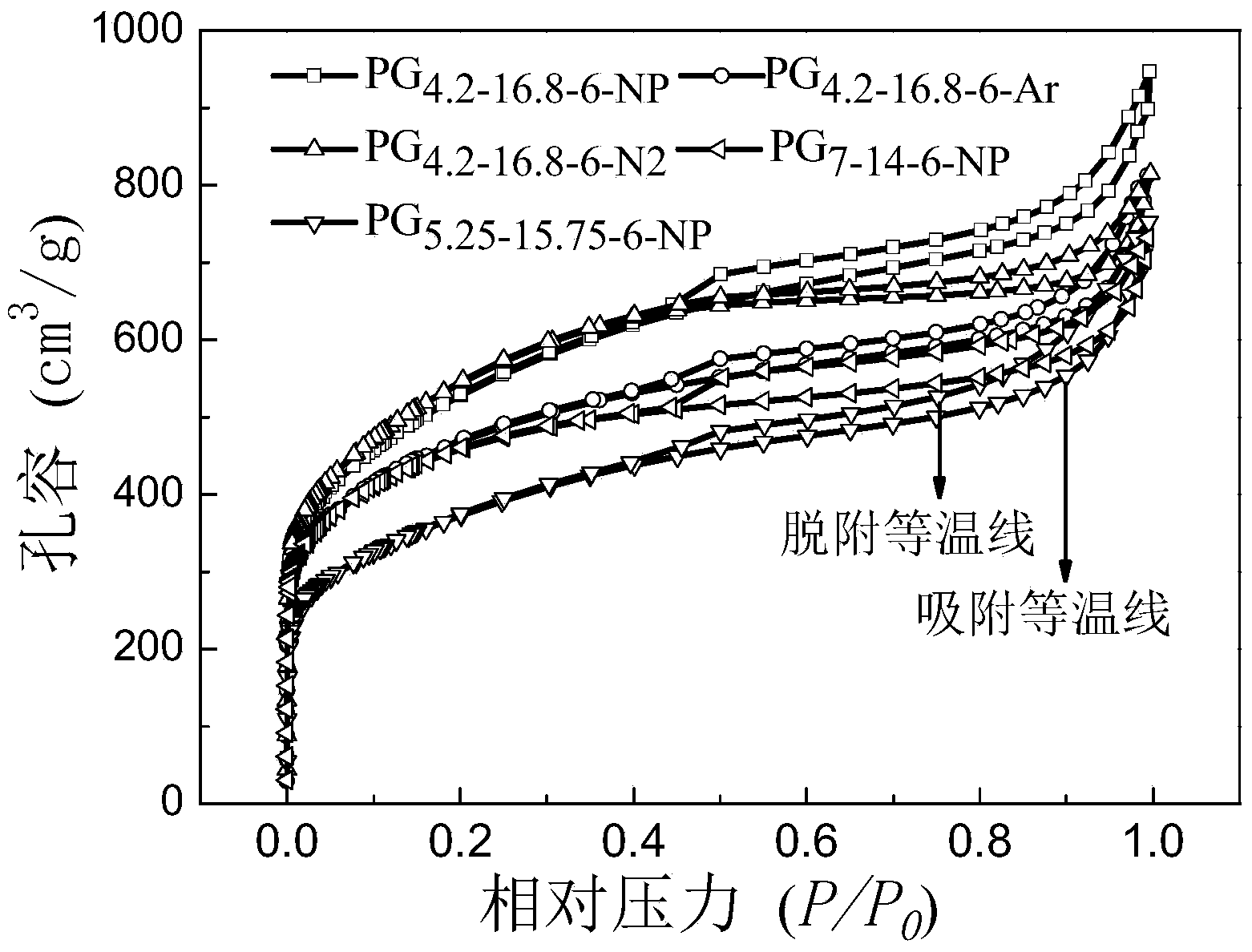

[0026] Porous graphene PG 4.2-16.8-6-NP The specific preparation process is as follows:

[0027] (1) Pretreatment of reactants: take 4.2g of coal tar pitch powder with a particle size less than 74 microns and put it into a mortar, add 16.8g of nano-calcium carbonate, and then add 6g of potassium hydroxide solid, and the mixture of the three obtained is ground evenly to obtain Reactant.

[0028] (2) Preparation of porous graphene material: put the reactant obtained in step (1) into a corundum porcelain boat, then place the corundum porcelain boat in a tube furnace, feed nitrogen in advance (flow rate is 60mL / min ) exhaust the air in the tube furnace, then pump the pressure in the tube furnace to -0.1MPa, and heat the tube furnace to 200°C at a heating rate of 5°C / min, Constant temperature for 0.5h, continue to heat the tube furnace to 750°C at a temperature increase rate of 5°C / min, keep the temperature constant for 1h, continue to heat the tube furnace to 950°C at a temperat...

Embodiment 2

[0030] Porous graphene PG 4.2-16.8-6-N2 The specific preparation process is as follows:

[0031] (1) Pretreatment of reactants: implement according to the same method as step (1) in Example 1.

[0032] (2) implement according to the same method as step (2) in embodiment 1, the difference is that the air pressure in the tube furnace is normal pressure, feeds N 2 The flow rate is 60mL / min, and the resulting porous graphene is marked as PG 4.2-16.8-6-N2 , its TEM photo is attached image 3shown. PG 4.2-16.8-6-N2 As supercapacitor electrode material in BMIMPF 6 Under the current density of 0.05A / g in the ionic liquid electrolyte, its specific volume is as high as 115F / g, PG 4.2-16.8-6-N2 The usable energy density of supercapacitors is as high as 65Wh / kg.

Embodiment 3

[0034] Porous graphene PG 4.2-16.8-6-Ar The specific preparation process is as follows:

[0035] (1) Pretreatment of reactants: implement according to the same method as step (1) in Example 1.

[0036] (2) implement according to the same method as step (2) in embodiment 2, difference is that the air pressure in the tube furnace is normal pressure, the flow that passes into argon is 60mL / min, and the gained porous graphene mark is PG 4.2-16.8-6-Ar , its TEM photo is attached Figure 4 shown. PG 4.2-16.8-6-Ar As supercapacitor electrode material in BMIMPF 6 Under the current density of 0.05A / g in the ionic liquid electrolyte, its specific volume is as high as 111F / g, PG 4.2-16.8-6-Ar The available energy density of supercapacitors is as high as 63Wh / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com