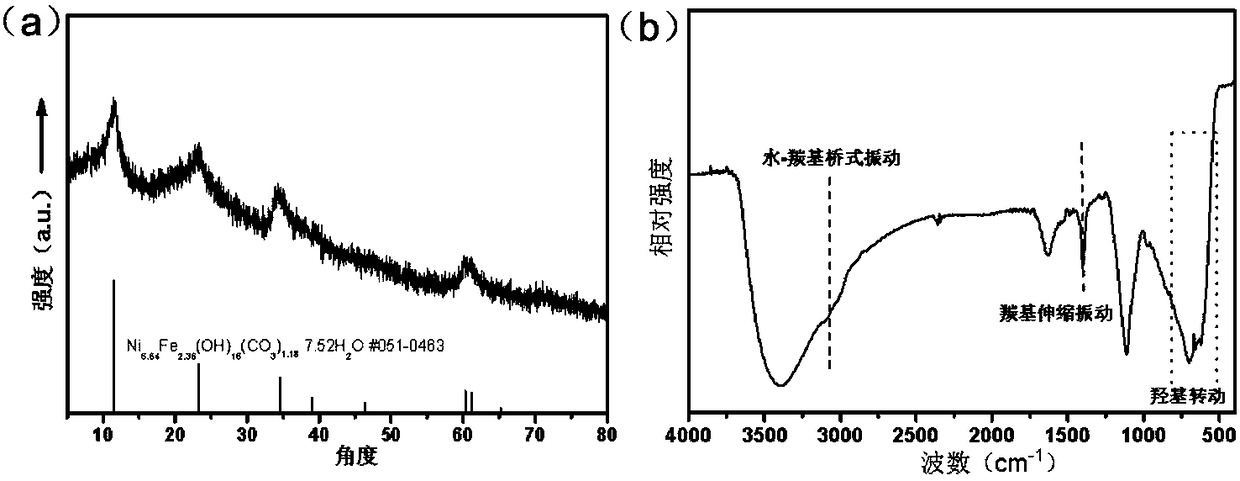

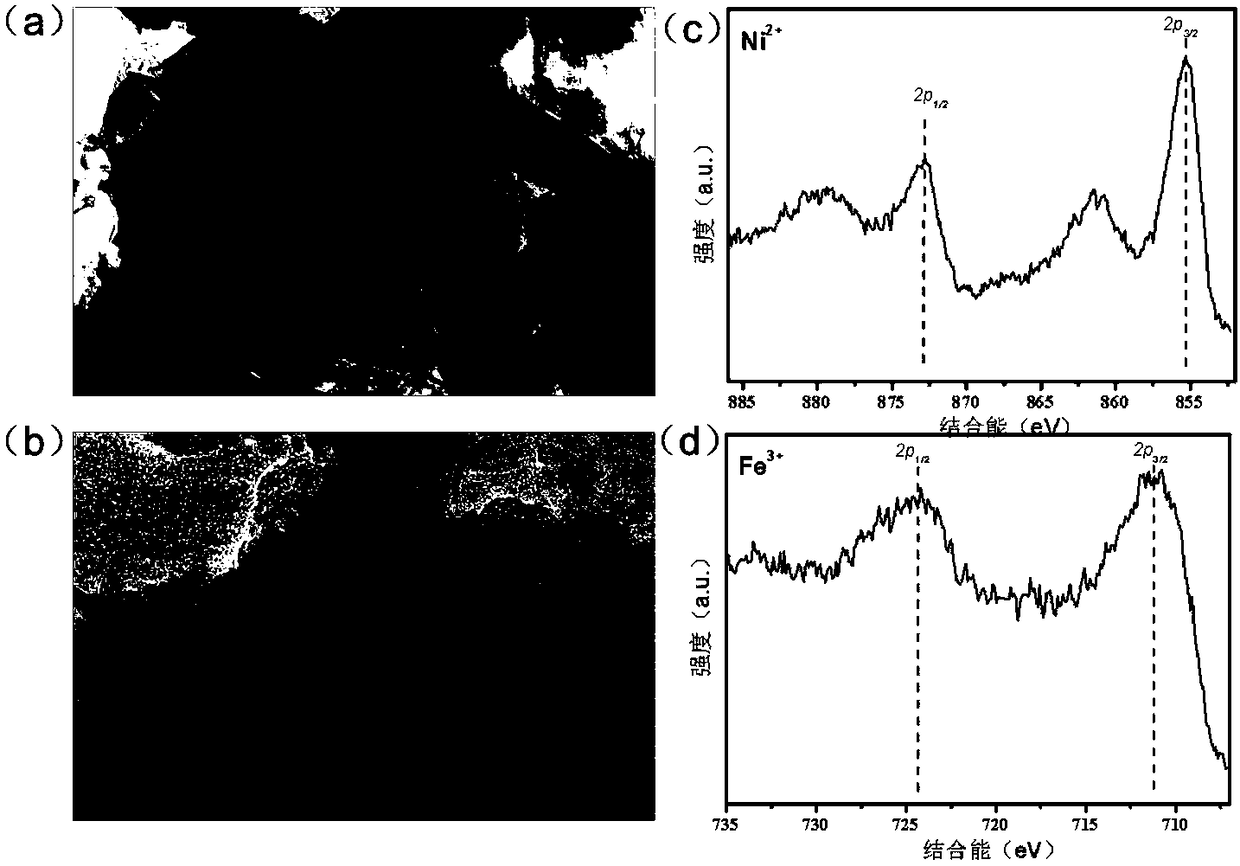

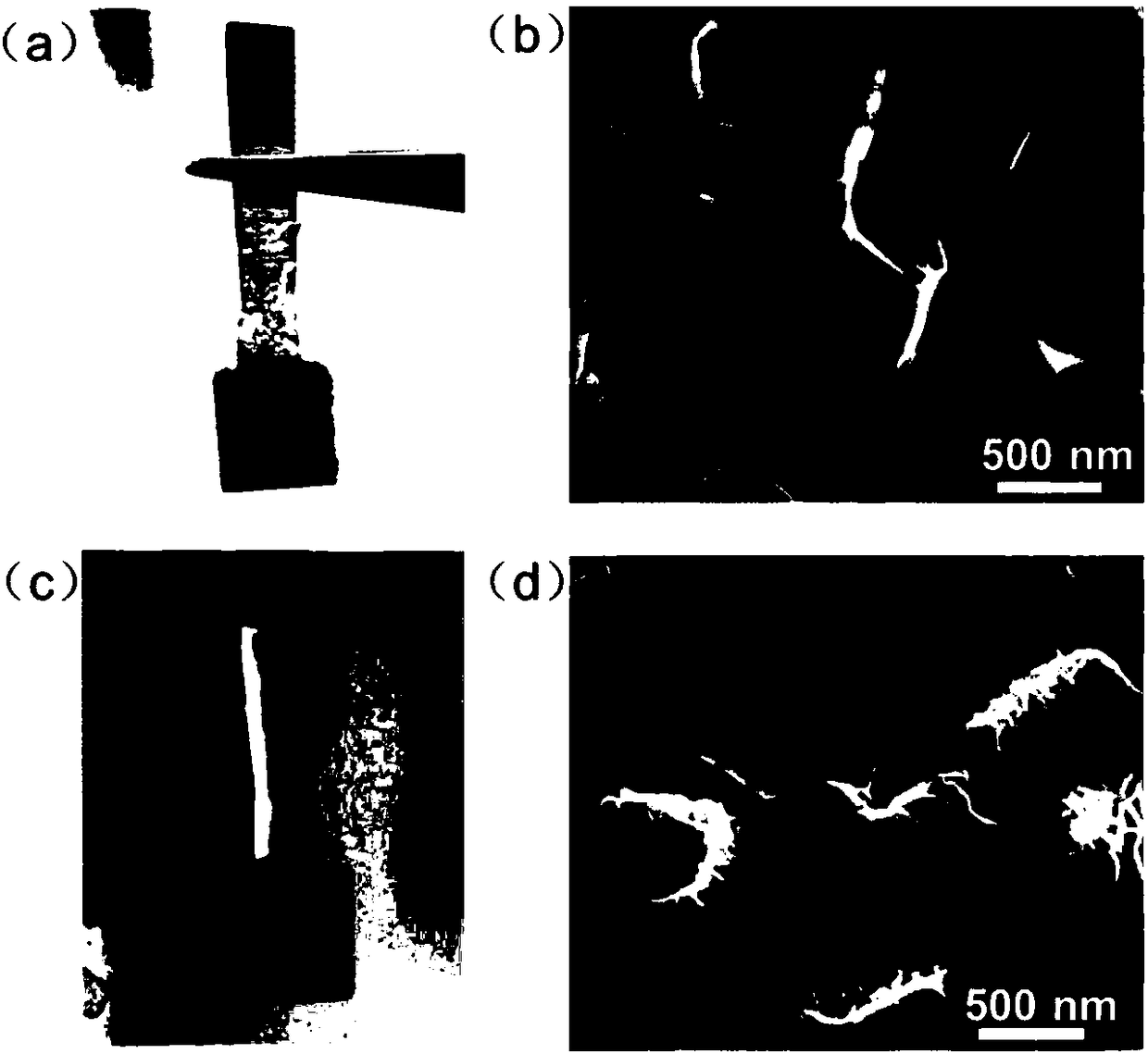

Nickel-iron hydrotalcite based electro-catalytic oxygen evolution electrode and preparation and application thereof

An oxygen evolution electrode, nickel molten iron technology, applied in the direction of electrode, electrode shape/type, electrolysis process, etc., can solve the problems of affecting the catalytic activity and life of the electrode, hindered charge transfer, complicated process, etc., to ensure charge transfer efficiency, improve Structural stability, simple and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of a nickel-iron hydrotalcite-based electrocatalytic oxygen evolution electrode is carried out according to the following steps.

[0026] (1) Nickel foam was ultrasonically cleaned in acetone for 10 minutes, cleaned in ultrapure water for 10 minutes, and repeated twice, ultrasonically in 1mol / L hydrochloric acid for 10 minutes, and finally cleaned in ultrapure water for 10 minutes, And repeat twice.

[0027] (2) Electrolyte preparation: directly dissolve nickel nitrate and ferrous sulfate in ultrapure water. The sum of the molar concentrations of nickel and iron elements is 50mmol / L, and the molar content of iron elements is 25%.

[0028] (3) With the nickel foam electrode processed in step (1) as the working electrode and the counter electrode, the saturated calomel electrode as the reference electrode, and the solution prepared in the step (2) as the electrolyte, assembled into a standard three-electrode system.

[0029] (4) Connect the three-e...

Embodiment 2

[0038] A preparation method of a nickel-iron hydrotalcite-based electrocatalytic oxygen evolution electrode is carried out according to the following steps.

[0039] (5) Nickel foam was ultrasonically cleaned in acetone for 10 minutes, cleaned in ultrapure water for 10 minutes, and repeated twice, ultrasonically in 1mol / L hydrochloric acid for 10 minutes, and finally cleaned in ultrapure water for 10 minutes, And repeat twice.

[0040] (6) Electrolyte preparation: directly dissolve nickel nitrate and ferrous sulfate in ultrapure water. The sum of the molar concentrations of nickel and iron elements is 50mmol / L, and the molar content of iron elements is 25%.

[0041] (7) With the nickel foam electrode processed in step (1) as the working electrode and the counter electrode, the saturated calomel electrode as the reference electrode, the solution prepared in the step (2) as the electrolyte, assembled into a standard three-electrode system.

[0042] (8) Connect the three-elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com