Preparation method of graphene film

A graphene film and graphene technology, applied in the direction of electrolytic inorganic material coating, etc., can solve the problem that the thickness of the film is difficult to control, and achieve the effect of controllable thickness, good quality and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Working electrode: clean the titanium-titania nanotube array composite electrode and set it aside;

[0025] (2) Prepare graphene oxide aqueous dispersion: graphene oxide is dispersed in 0.1mol / L Na 2 HPO 4 In the buffer solution, sonicate for 30 minutes and set aside;

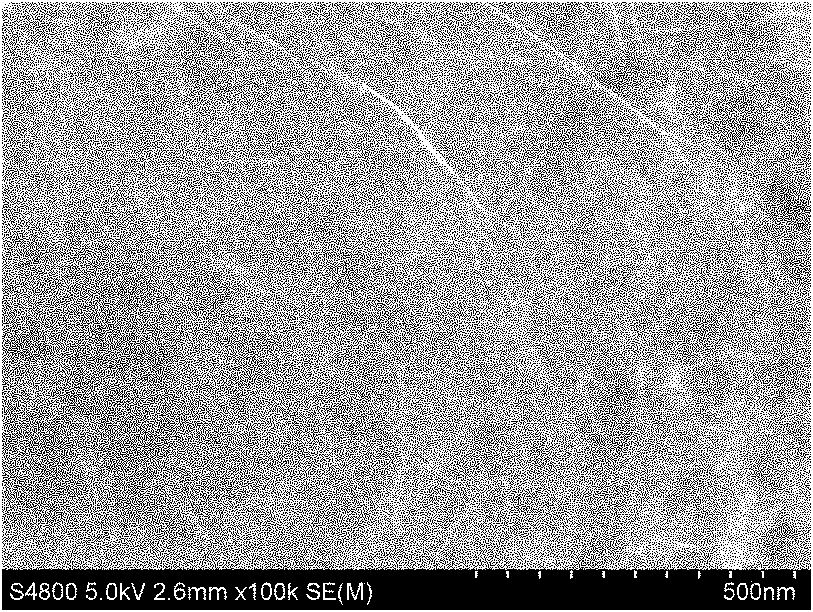

[0026] (3) Preparation of graphene film: the titanium-titania nanotube array composite electrode is used as the working electrode, the platinum electrode is used as the counter electrode, and the saturated calomel electrode is used as the reference electrode, and the above three electrodes are placed in the graphene oxide aqueous dispersion In this study, cyclic voltammetric electroreduction and graphene deposition were performed on an electrochemical workstation, with a scanning voltage range of -1.5 volts to 1 volt, and a scanning rate of 50 millivolts per second. figure 1 It is a scanning electron microscope image of graphene film deposited on the electrode surface of titanium-titania nanotube a...

Embodiment 2

[0028] (1) working electrode: with embodiment 1;

[0029] (2) preparation of graphene oxide aqueous dispersion: with embodiment 1;

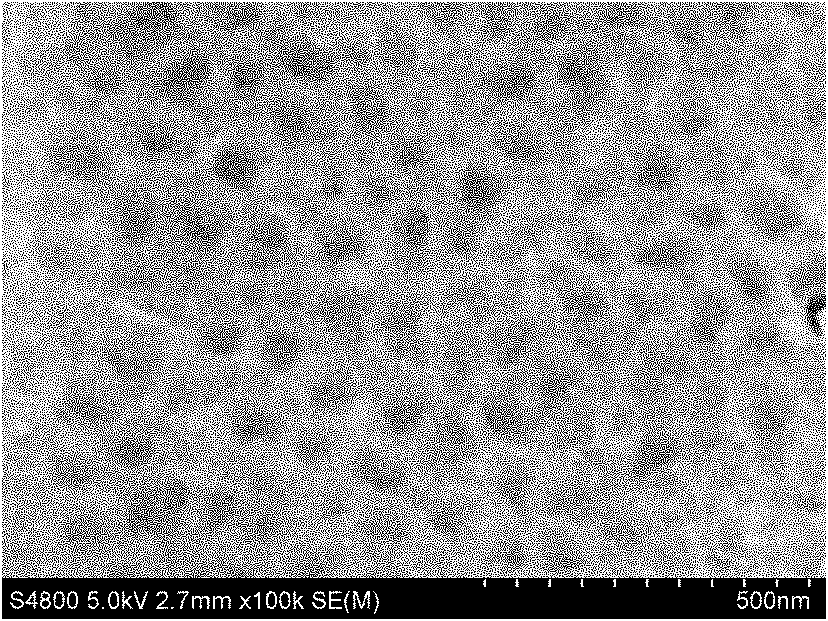

[0030] (3) Preparation of graphene film: the titanium-titania nanotube array composite electrode is used as the working electrode, the platinum electrode is used as the counter electrode, and the saturated calomel electrode is used as the reference electrode, and the above three electrodes are placed in the graphene oxide aqueous dispersion In this method, pulse voltage electroreduction and graphene deposition were carried out on the electrochemical workstation, the power-on voltage was -1.3 volts, and the pulse time on-off ratio was 0.5 seconds: 1.0 seconds. figure 2 It is a scanning electron microscope image of graphene film deposited on the electrode surface of titanium-titania nanotube array composite.

Embodiment 3

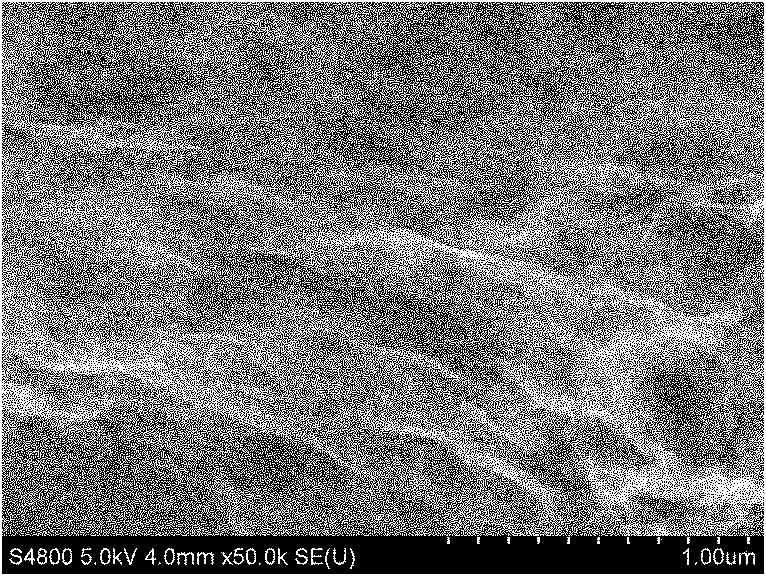

[0032] The titanium-titania nanotube array composite electrode in Example 1 was replaced by an aluminum-alumina electrode, and the rest were the same as in Example 1. image 3 It is a scanning electron microscope image of a graphene film deposited on the surface of an aluminum-alumina electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com