Double-layer enveloped slow/controlled release fertilizer and preparation method thereof

A technology of controlled-release fertilizer and double-layer coating, which is applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of reduced grain yield and low utilization rate of natural precipitation, and achieves improved utilization rate, good degradability, and extended irrigation cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

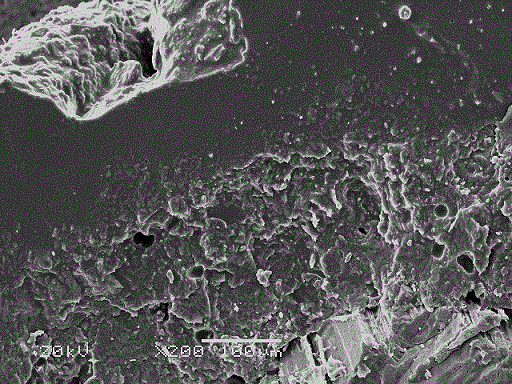

Image

Examples

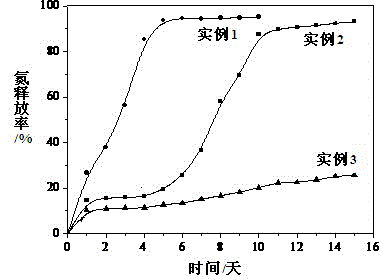

Embodiment 1

[0018] (1) Preparation of starch-modified polyacrylic acid water-absorbent resin

[0019] Add 40g of cornstarch to the reaction flask, add distilled water, stir and gelatinize in a water bath with a constant temperature of 80°C for 20min, after the gelatinization is complete, lower the temperature of the system to 40°C; add 50g of sodium hydroxide solution with a mass concentration of 20% Neutralized acrylic acid with a neutralization degree of 60%, then add 0.2g of crosslinking agent N, N-methylenebisacrylamide and 0.5g of initiator ammonium persulfate, then raise the temperature of the system to 70°C for constant temperature polymerization for 1.5h, Shred, dry at 70°C, pass through a 100-mesh sieve after crushing to obtain a starch-modified polyacrylic acid water-absorbing resin;

[0020] (2) Preparation of double-layer coated slow / controlled release fertilizer

[0021] Add 60g of urea granules with an average particle size of 2mm into the coating machine, spray rosin e...

Embodiment 2

[0023] (1) Preparation of starch-modified polyacrylic acid water-absorbent resin

[0024] Add 40g of cornstarch to the reaction flask, add distilled water, stir and gelatinize in a water bath with a constant temperature of 80°C for 20min, after the gelatinization is complete, lower the temperature of the system to 40°C; add 50g of sodium hydroxide solution with a mass concentration of 20% Neutralized acrylic acid with a neutralization degree of 60%, then add 0.2g of crosslinking agent N, N-methylenebisacrylamide and 0.5g of initiator ammonium persulfate, then raise the temperature of the system to 70°C for constant temperature polymerization for 1.5h, Shred, dry at 70°C, pass through a 100-mesh sieve after crushing to obtain a starch-modified polyacrylic acid water-absorbing resin;

[0025] (2) Preparation of double-layer coated slow / controlled release fertilizer

[0026] Add 60g of urea particles with an average particle size of 2mm into the coating machine, spray rosin etha...

Embodiment 3

[0028] (1) Preparation of starch-modified polyacrylic acid water-absorbent resin

[0029] Add 40g of cornstarch to the reaction flask, add distilled water, stir and gelatinize in a water bath with a constant temperature of 80°C for 20min, after the gelatinization is complete, lower the temperature of the system to 40°C; add 50g of sodium hydroxide solution with a mass concentration of 20% Neutralized acrylic acid with a neutralization degree of 60%, then add 0.2g of crosslinking agent N, N-methylenebisacrylamide and 0.5g of initiator ammonium persulfate, then raise the temperature of the system to 70°C for constant temperature polymerization for 1.5h, Shred, dry at 70°C, pass through a 100-mesh sieve after crushing to obtain a starch-modified polyacrylic acid water-absorbing resin;

[0030] (2) Preparation of double-layer coated slow / controlled release fertilizer

[0031]Add 50g of urea particles with an average particle size of 2mm into the coating machine, spray rosin ethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com