Production device and production method of double slow release high dispersion medicinal fertilizer

A production device and high-dispersion technology, applied in fertilization devices, layered/coated fertilizers, nitrogen fertilizers, etc., can solve the problems of limited types of pesticides, narrow product application areas, and small application scopes, and improve the utilization rate of raw materials and the use of medicines. The effect of short duration of effect and low solvent volatilization point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

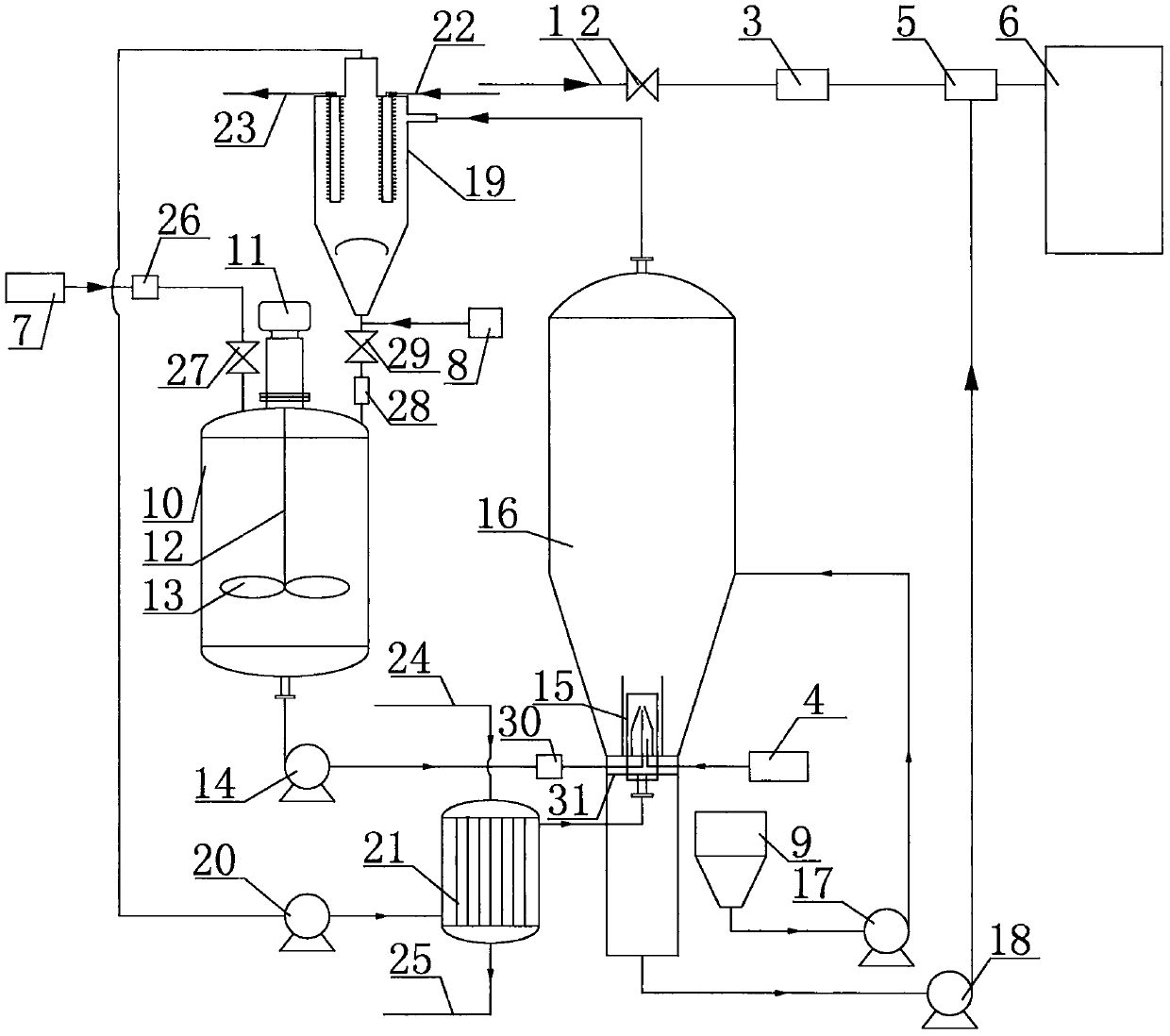

[0032] A double slow-release high-dispersion fertilizer production device includes a urea solution pipeline 1, a urea solution pipeline 1 passing through a third valve 2, a fourth flow meter 3, a first inlet of a pipeline mixer 5, an outlet of a pipeline mixer 5, and a granulation system 6 are connected, and the second inlet of the pipeline mixer 5 is connected with the fertilizer emulsification device; the fertilizer emulsification device includes a pesticide tank 7, a solvent tank 8 and a fertilizer carrier tank 9, and the pesticide tank 7 is connected to the top side of the emulsification tank 10 through a pipeline, The solvent tank 8 is connected to the other side of the top of the emulsification tank 10 through a tee, and the emulsification tank motor 11 is arranged on the middle position of the top of the emulsification tank 10, and the emulsification tank motor 11 is connected to the stirring shaft 12 inside the emulsification tank 10. 12 is connected to the stirring bla...

Embodiment 2

[0042] A double slow-release high-dispersion fertilizer production device includes a urea solution pipeline 1, a urea solution pipeline 1 passing through a third valve 2, a fourth flow meter 3, a first inlet of a pipeline mixer 5, an outlet of a pipeline mixer 5, and a granulation system 6 are connected, and the second inlet of the pipeline mixer 5 is connected with the fertilizer emulsification device; the fertilizer emulsification device includes a pesticide tank 7, a solvent tank 8 and a fertilizer carrier tank 9, and the pesticide tank 7 is connected to the top side of the emulsification tank 10 through a pipeline, The solvent tank 8 is connected to the other side of the top of the emulsification tank 10 through a tee, and the emulsification tank motor 11 is arranged on the middle position of the top of the emulsification tank 10, and the emulsification tank motor 11 is connected to the stirring shaft 12 inside the emulsification tank 10. 12 is connected to the stirring bla...

Embodiment 3

[0052] A double slow-release high-dispersion fertilizer production device includes a urea solution pipeline 1, a urea solution pipeline 1 passing through a third valve 2, a fourth flow meter 3, a first inlet of a pipeline mixer 5, an outlet of a pipeline mixer 5, and a granulation system 6 are connected, and the second inlet of the pipeline mixer 5 is connected with the fertilizer emulsification device; the fertilizer emulsification device includes a pesticide tank 7, a solvent tank 8 and a fertilizer carrier tank 9, and the pesticide tank 7 is connected to the top side of the emulsification tank 10 through a pipeline, The solvent tank 8 is connected to the other side of the top of the emulsification tank 10 through a tee, and the emulsification tank motor 11 is arranged on the middle position of the top of the emulsification tank 10, and the emulsification tank motor 11 is connected to the stirring shaft 12 inside the emulsification tank 10. 12 is connected to the stirring bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com