Slow-release high-tower pesticide fertilizer and preparation method thereof

A slow-release, medicated fertilizer technology, applied in nitrogen fertilizers, potash fertilizers, inorganic fertilizers, etc., can solve problems such as economic waste, environmental pollution, and lack of mature technology for medicated fertilizers, to ensure activity, ensure growth requirements, and achieve effective utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

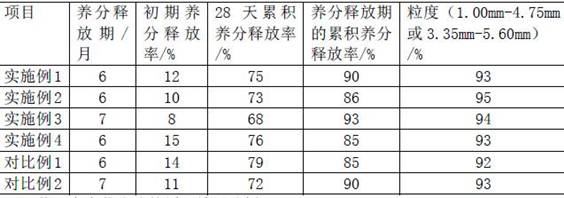

Examples

Embodiment 1

[0025] A preparation method of slow-release high-tower medicinal fertilizer, comprising the following steps:

[0026] (1) 200kg of urea is added to the melting tank, the temperature of the melting tank is controlled at 120-125°C, and the melted urea solution overflows to the primary tank;

[0027] (2) Add 100kg of potash fertilizer and 150kg of stone powder as an auxiliary material into the primary tank, mix evenly with the urea solution, control the temperature of the primary tank at 110-115°C, and the mixed molten material overflows to the secondary tank;

[0028] (3) Add 80kg of phosphate fertilizer, 3.8kg of nitrification inhibitor, and 0.64kg of pesticide powder to the secondary tank, and mix with the molten material for less than 4 minutes to obtain a mixed molten slurry. The temperature of the secondary tank is controlled at 100-105°C;

[0029] (4) Emulsify the mixed molten material, granulate and screen, and cool the qualified product to 40-50°C;

[0030] (5) After co...

Embodiment 2

[0033] A preparation method of slow-release high-tower medicinal fertilizer, comprising the following steps:

[0034] (1) 200 kg of urea is added to the melting tank, the temperature of the melting tank is controlled at 120-125°C, and the melted urea solution overflows to the primary tank;

[0035] (2) Add 100 kg of potash fertilizer and 150 kg of stone powder as an auxiliary material into the first-level tank and mix them evenly with the urea solution. The temperature of the first-level tank is controlled at 110-115°C, and the mixed molten material overflows to the second-level tank;

[0036] (3) Add 100 kg of phosphate fertilizer, 4.0 kg of nitrification inhibitor, and 2.0 kg of pesticide powder to the secondary tank, and mix with the molten material for less than 4 minutes to obtain a mixed molten slurry. The temperature of the secondary tank is controlled at 100 -105 °C;

[0037] (4) Emulsify the mixed molten material, granulate and screen, and cool the qualified product t...

Embodiment 3

[0041] A preparation method of slow-release high-tower medicinal fertilizer, comprising the following steps:

[0042] (1) 200kg of urea is added to the melting tank, the temperature of the melting tank is controlled at 120-125°C, and the melted urea solution overflows to the primary tank;

[0043] (2) Add 50kg of potash fertilizer and 200kg of auxiliary stone powder into the primary tank, and mix them evenly with the urea solution. The temperature of the primary tank is controlled at 110-115°C, and the mixed molten material overflows to the secondary tank;

[0044] (3) Add 50kg of phosphate fertilizer, 1.5 kg of urease inhibitor, and 1.0kg of pesticide powder to the secondary tank, and mix with the molten material for less than 4 minutes to obtain a mixed molten slurry. The temperature of the secondary tank is controlled at 100-105°C;

[0045] (4) Emulsify the mixed molten material, granulate and screen, and cool the qualified product to 40-50°C;

[0046] (5) After cooling, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com