Pesticide microcapsule

A technology of microcapsules and pesticides, applied in the fields of pesticides, animal repellents, botanical equipment and methods, etc., can solve the problems of difficulty in achieving sustained release, poor sustained release performance, easy oxidative decomposition, etc., and achieve improved stability. , good stability, easy to disperse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

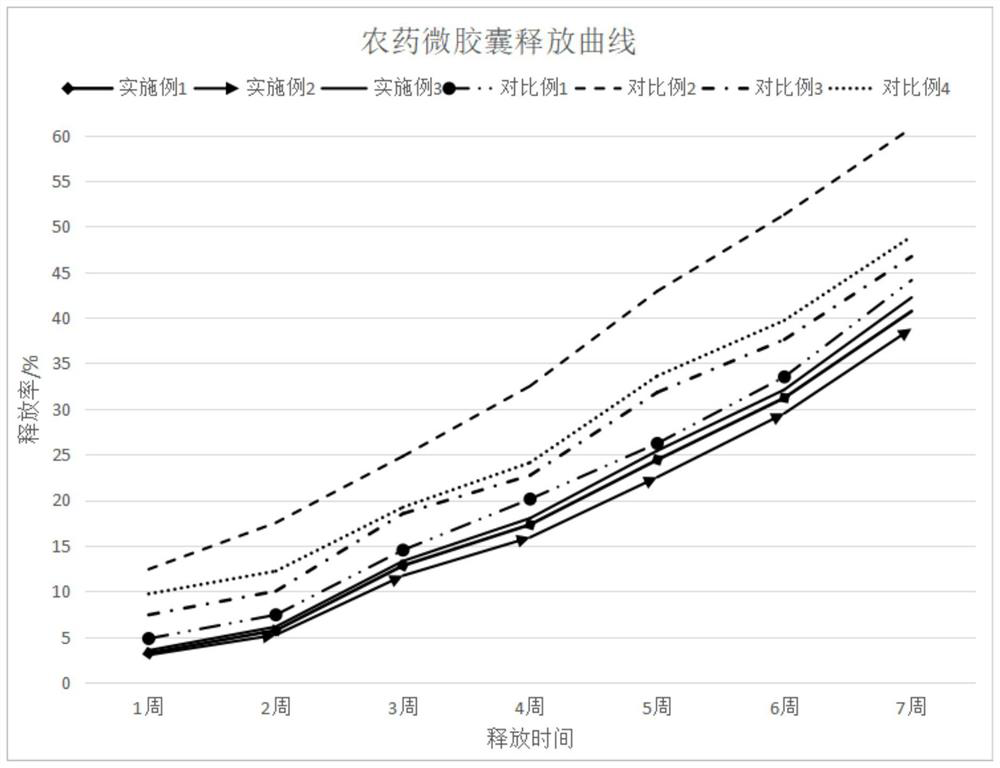

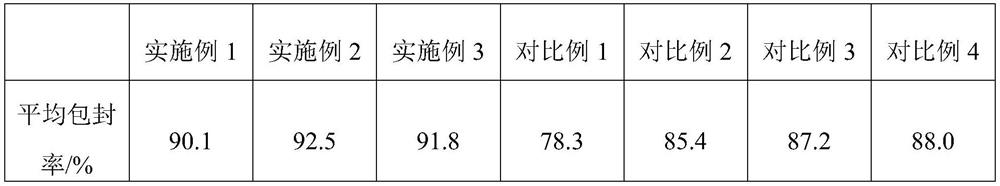

Examples

Embodiment 1

[0068] A pesticide microcapsule prepared by the following method:

[0069] 1) Add gelatin and dodecylphenol polyoxyethylene ether into deionized water, dissolve at 55°C, and stir at 700r / min to obtain a mixed solution;

[0070] 2) Add fipronil to the mixed solution obtained in step 1), and stir at 3500r / min to form a core material emulsion;

[0071] 3) dissolving chitosan in 0.5% glacial acetic acid solution, adding sodium lignosulfonate under stirring, adjusting the pH value to 7.5, adding calcium chloride, and stirring to obtain a wall material solution;

[0072] 4) Add the core material emulsion obtained in step 2) to the wall material solution obtained in step 3), and stir at 400r / min for 25min;

[0073] 5) Add the reinforcing agent to deionized water, then add γ-methacryloxypropyltrimethoxysilane, stir for 5 minutes, and ultrasonically disperse for 10 minutes to obtain a reinforcing agent dispersion;

[0074] Add the reinforcing agent dispersion to the solution obtained...

Embodiment 2

[0085] A pesticide microcapsule prepared by the following method:

[0086] 1) Add gelatin and dodecylphenol polyoxyethylene ether into deionized water, dissolve at 60°C, and stir at 1000r / min to obtain a mixed solution;

[0087] 2) Add fipronil to the mixed solution obtained in step 1), and stir at 3500r / min to form a core material emulsion;

[0088] 3) dissolving chitosan in 1% glacial acetic acid solution, adding sodium lignosulfonate under stirring, adjusting the pH value to 7.5, adding calcium chloride, and stirring to obtain a wall material solution;

[0089] 4) Add the core material emulsion obtained in step 2) to the wall material solution obtained in step 3), and stir at 600r / min for 25min;

[0090] 5) The reinforcing agent is added to deionized water, and then γ-methacryloxypropyltrimethoxysilane is added, stirred for 7 minutes, and ultrasonically dispersed for 15 minutes to obtain a reinforcing agent dispersion;

[0091] Add the reinforcing agent dispersion to the ...

Embodiment 3

[0102] A pesticide microcapsule prepared by the following method:

[0103] 1) Add gelatin and dodecylphenol polyoxyethylene ether into deionized water, dissolve at 60°C, and stir at 1000r / min to obtain a mixed solution;

[0104] 2) Add fipronil to the mixed solution obtained in step 1), and stir at 4000r / min to form a core material emulsion;

[0105] 3) dissolving chitosan in 1% glacial acetic acid solution, adding sodium lignosulfonate under stirring, adjusting the pH value to 7.5, adding calcium chloride, and stirring to obtain a wall material solution;

[0106] 4) Add the core material emulsion obtained in step 2) to the wall material solution obtained in step 3), and stir at 700r / min for 20min;

[0107] 5) Add the reinforcing agent to deionized water, then add γ-methacryloxypropyltrimethoxysilane, stir for 5 minutes, and ultrasonically disperse for 10 minutes to obtain a reinforcing agent dispersion;

[0108] Add the reinforcing agent dispersion to the solution obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com