Magnesium phosphate cement based rapid repair mortar and preparation method thereof

A magnesium phosphate cement and repair mortar technology, which is applied in the field of magnesium phosphate cement-based rapid repair mortar and its preparation, can solve problems such as insufficient water resistance, achieve the effects of improving performance indicators, improving water resistance, and avoiding cracking of the repair surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

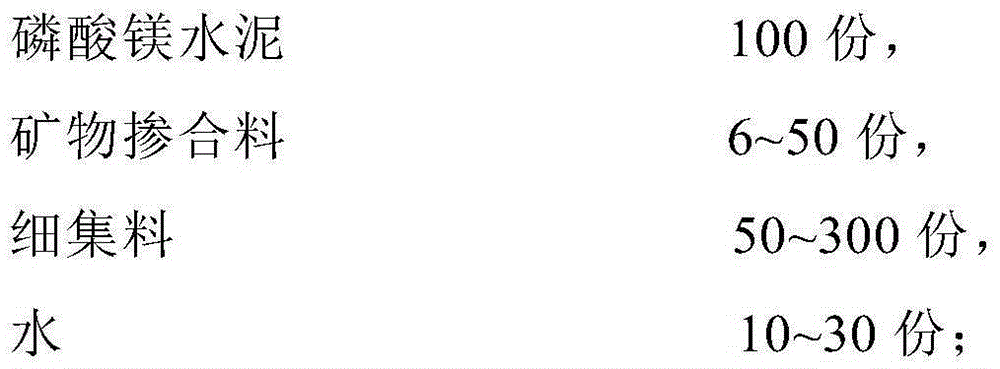

[0040] A magnesium phosphate cement-based rapid repair mortar, comprising the following components in parts by weight:

[0041]

[0042] Magnesium phosphate cement is made by mixing 66.5 parts by weight of metal oxide powder, 24 parts of phosphate, 5 parts of retarder and 4.5 parts of setting adjustment components. The metal oxide powder is dead-burned magnesium oxide powder with a purity of more than 90%, fineness less than 200 mesh, phosphate is potassium dihydrogen phosphate, industrial grade product, purity greater than 98%, retarder borax, industrial grade product, purity greater than 98%, coagulation adjustment component is K 2 HPO 4, The fine aggregate is a mixture of river sand and quartz sand with a fineness modulus of 2 to 3 and a maximum particle size of 4.75mm.

[0043] The described rapid repair mortar is prepared through the following steps: weighing various raw materials according to the above-mentioned proportions, adding retarder borax, K 2 HPO 4 Dissolv...

Embodiment 2

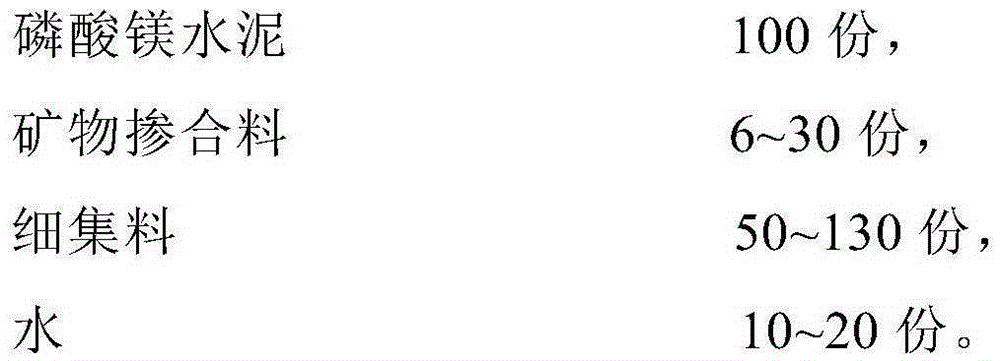

[0045] A magnesium phosphate cement-based rapid repair mortar, comprising the following components in parts by weight:

[0046]

[0047] Magnesium phosphate cement is made by mixing 60 parts by weight of metal oxide powder, 28 parts of phosphate, 6 parts of retarder and 6 parts of setting adjustment components. The metal oxide powder is dead-burned magnesium oxide powder with a purity greater than 90%, fineness less than 200 mesh, phosphate is potassium dihydrogen phosphate, industrial grade product, purity greater than 98%, retarder borax, industrial grade product, purity greater than 98%, coagulation adjustment component is K 2 HPO 4 ·3H 2 O, the fine aggregate is machine-made sand with a fineness modulus of 2 to 3 and a maximum particle size of 4.75mm.

[0048] Weigh various raw materials according to the above proportions, mix evenly with reference to the preparation method of Example 1, and obtain a magnesium phosphate cement-based rapid repair mortar with excellent ...

Embodiment 3

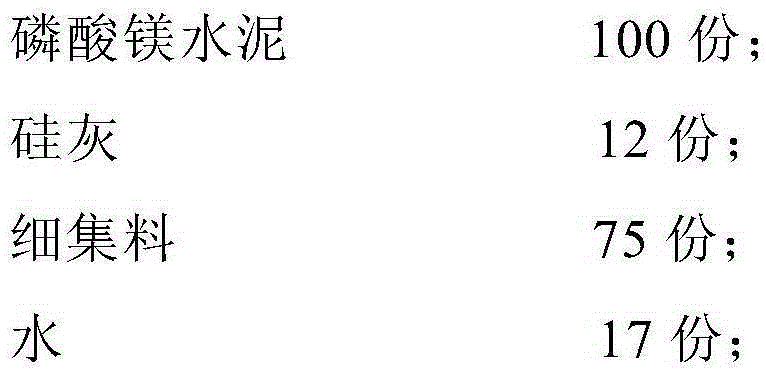

[0050] A magnesium phosphate cement-based rapid repair mortar, comprising the following components in parts by weight:

[0051]

[0052] Magnesium phosphate cement is made by mixing 70 parts by weight of metal oxide powder, 20 parts of phosphate, 5 parts of retarder and 5 parts of setting adjustment components. The metal oxide powder is dead-burned magnesium oxide powder with a purity greater than 90%, fineness less than 200 mesh, phosphate is potassium dihydrogen phosphate, industrial grade product, purity greater than 98%, retarder borax, industrial grade product, purity greater than 98%, coagulation adjustment component is K 2 HPO 4 ·3H 2 O and K 2 HPO 4 It is mixed at a mass ratio of 1:1, and the fine aggregate is river sand with a fineness modulus of 2 to 3 and a maximum particle size of 4.75mm.

[0053] Weigh various raw materials according to the above proportions, and mix them evenly with reference to Example 1 to obtain a magnesium phosphate cement-based rapid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com