High-stability thermosensitive paper and preparation method thereof

A heat-sensitive paper and high-performance technology, applied in the field of papermaking, can solve problems such as fading, prone to reverse reactions, and affecting the use effect, and achieve the effects of improving stability, ensuring water resistance, and high water preservation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

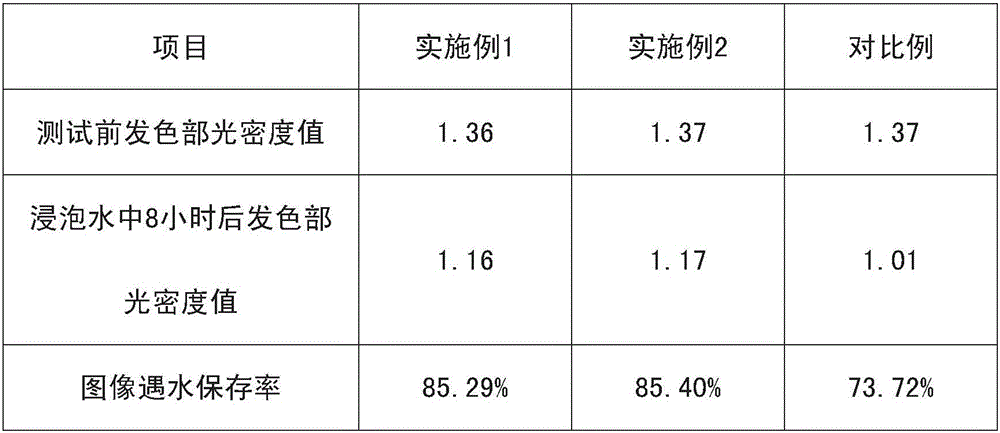

Examples

Embodiment 1

[0032] A heat-sensitive paper with high stability, including a base paper layer, a pre-coat layer and a color-developing layer.

[0033] The composition of the pre-coat is: 50 parts of filler, 10 parts of adhesive; the coating amount of pre-coat is controlled at 11g / m 2 .

[0034] The chromophoric layer was prepared as follows:

[0035] Preparation of color developer dispersion: 35 parts of 2,4 diphenylsulfone phenol, 3 parts of polyvinyl alcohol, mixed and dispersed to form a dispersion with a concentration of 35%, and ground in a wet grinder until the particle size is 1 μm;

[0036] Preparation of sensitizer dispersion: 35 parts of 1,2 diphenoxyethane, 3 parts of polyvinyl alcohol, mixed and dispersed to form a dispersion with a concentration of 35%, and ground in a wet grinder until the particle size is 0.8 μm;

[0037] Preparation of dye dispersion: 35 parts of 2-(2-4-xylanilino)-3-methyl-6-diethylaminofluorane, 3 parts of polyvinyl alcohol, mixed and dispersed into a di...

Embodiment 2

[0043] A heat-sensitive paper with high stability, including a base paper layer, a pre-coat layer and a color-developing layer.

[0044] The composition of the pre-coating is: 100 parts of filler, 25 parts of adhesive; the amount of pre-coating is controlled at 11g / m 2 .

[0045] The chromophoric layer was prepared as follows:

[0046] Preparation of color developer dispersion: 35 parts of 4,4'-sulfonyl bis[2-(2-propenyl)]phenol, 5 parts of polyvinyl alcohol, mixed and dispersed to form a dispersion with a concentration of 35%, in a wet grinder Grinding to a particle size of 1 μm;

[0047] Preparation of sensitizer dispersion: 35 parts of diphenyl sulfone, 5 parts of polyvinyl alcohol, mixed and dispersed to form a dispersion with a concentration of 35%, and ground in a wet grinder until the particle size is 0.8 μm;

[0048] Preparation of dye dispersion: 35 parts of 2-(2-4-xylanilino)-3-methyl-6-diethylaminofluorane, 5 parts of polyvinyl alcohol, mixed and dispersed into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com