Enclosure structure combined with prefabricated members and mixing wall and construction method

A technology of prefabricated components and enclosure structures, which is applied in the direction of foundation structure engineering, excavation, sheet pile walls, etc., can solve the problems of high-strength steel bars with poor bendability and welding performance, poor lap joints, and low relaxation, etc., and achieve construction efficiency The effect of high height, fast pile sinking speed and fast wall forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

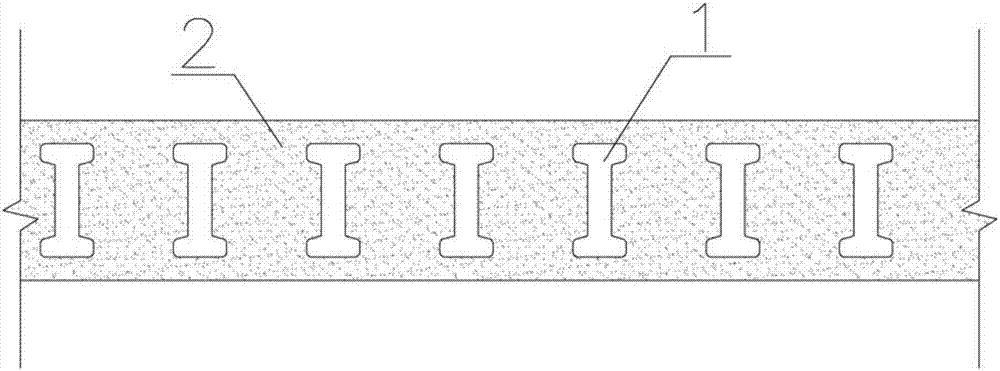

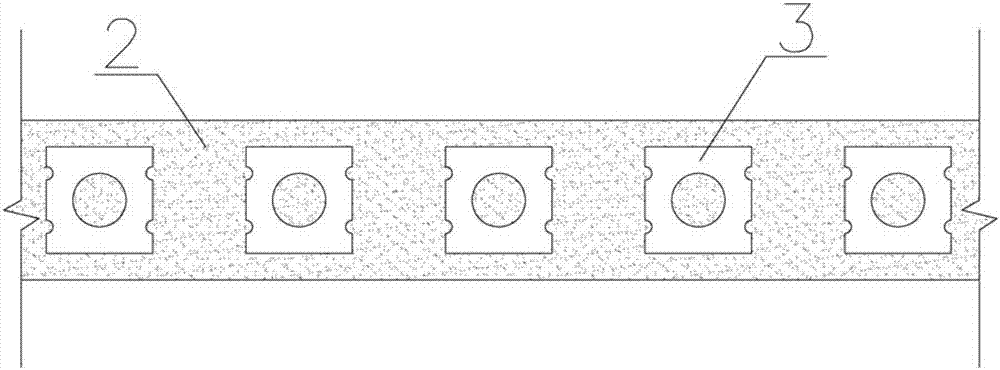

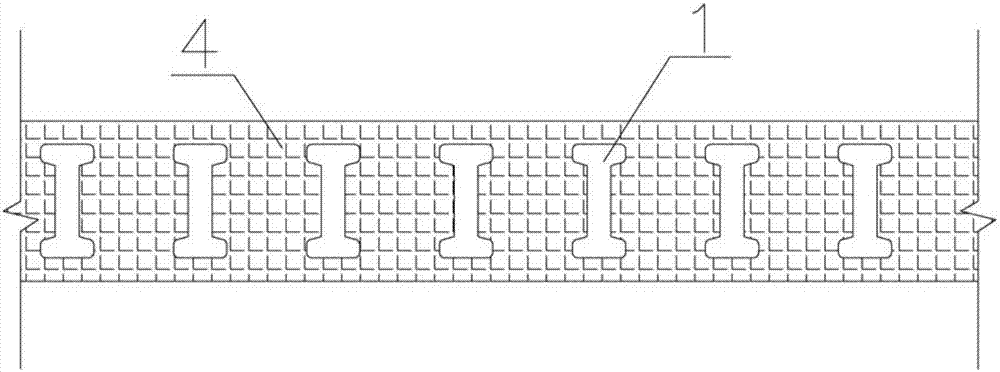

[0045] Such as Figure 1-4 As shown, an enclosure structure and construction method combining prefabricated components and mixing walls. The enclosure structure is suitable for foundation pit and river channel enclosure retaining soil and water stop. The prefabricated components have two forms: one is the urban and land assembled H-shaped enclosure pile component 1, and the other is the prefabricated centrifugal rectangular pile enclosure for water stop. Protective structure3. The mixing wall is a continuous square cement-soil mixing wall, which can be completed by two construction methods, one is the TRD construction method, that is, the TRD construction method mixing wall 2, and the other is the CSM construction method, that is, the CSM construction method mixing wall 4. The prefabricated components are pressed into the mixing wall according to requirements to form the enclosure.

[0046] There are two construction methods for an enclosure structure combining prefabricate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com