Alloy keel structure and manufacturing method thereof

A manufacturing method and alloy technology, applied in building construction, covering/lining, construction, etc., can solve the problems of increased labor intensity, inconvenient construction operation, secondary handling, etc., to reduce labor intensity, improve labor efficiency, and save man-hours Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

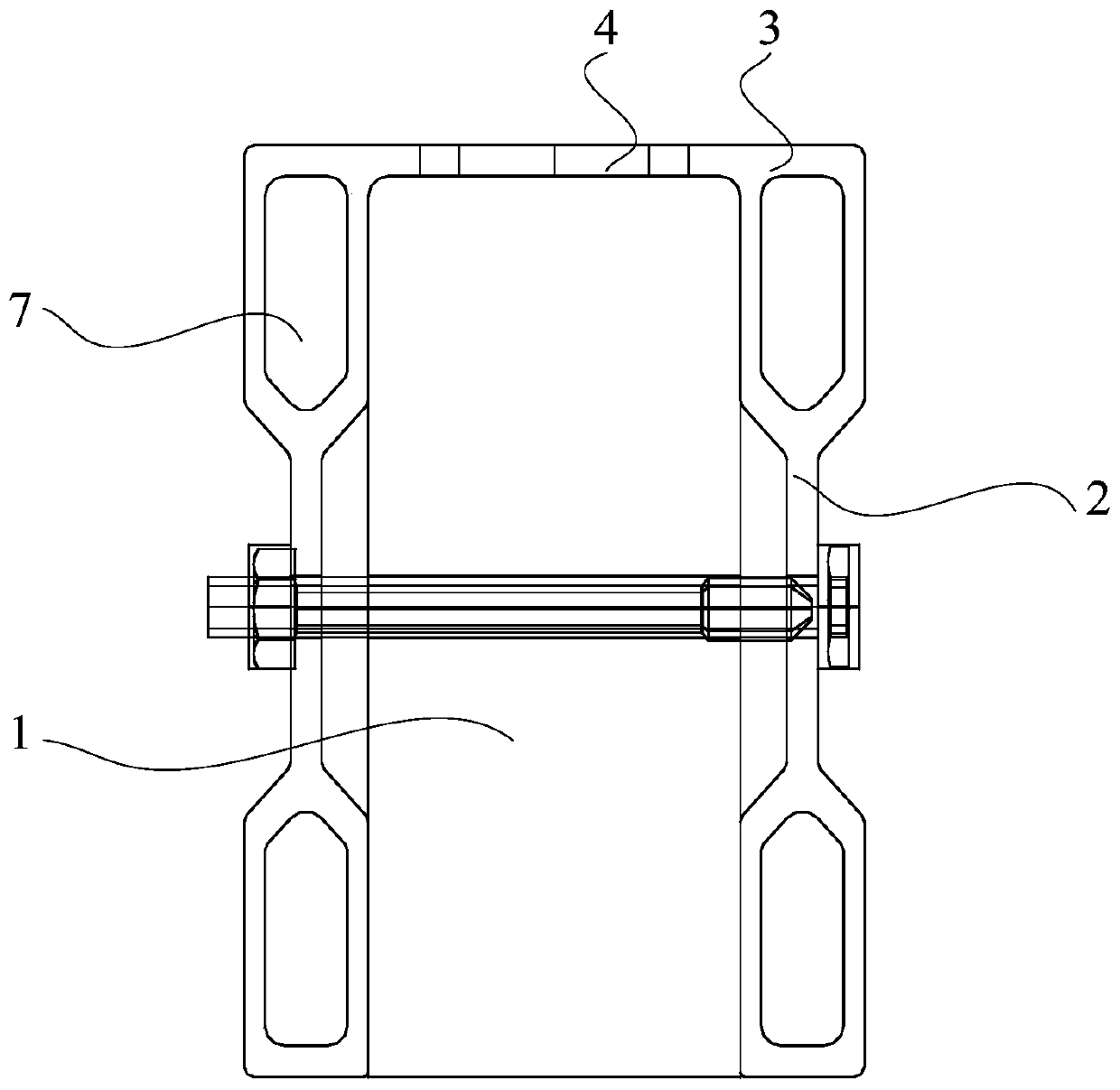

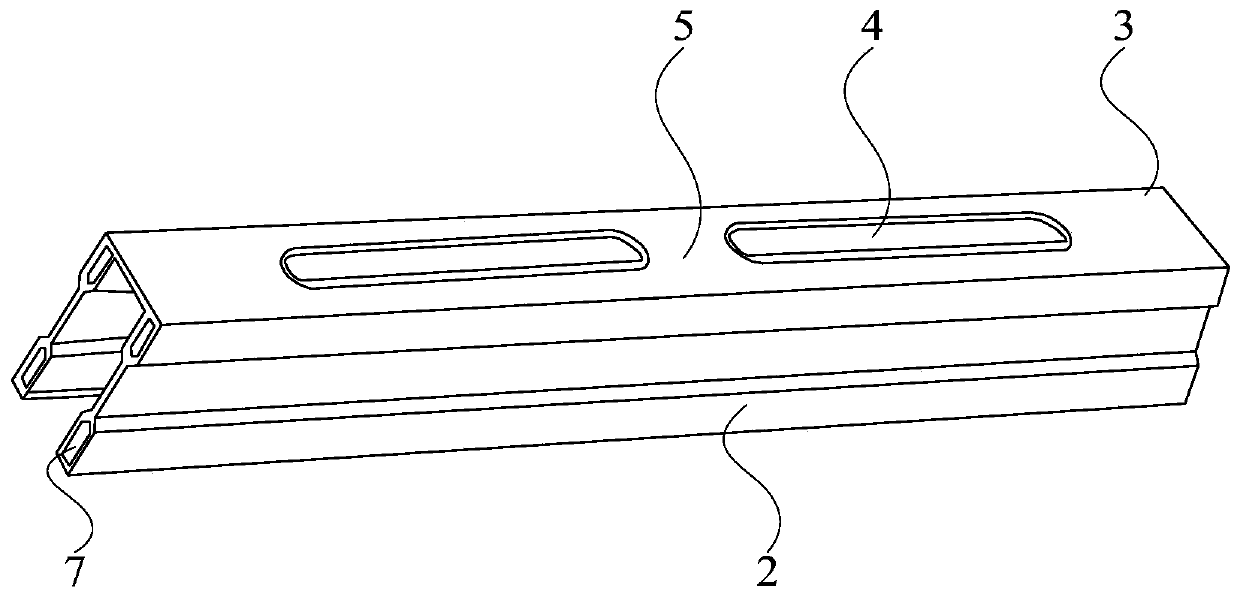

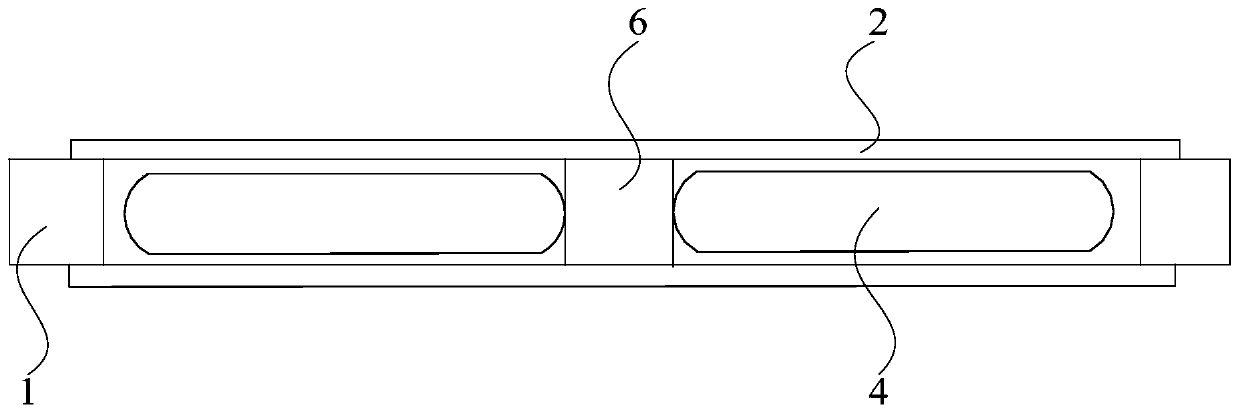

[0024] figure 1 Is a schematic structural view of an embodiment of an alloy keel structure of the present invention; figure 2 It is a schematic diagram of the main keel body structure of an embodiment of the alloy keel structure of the present invention; image 3 It is a top view of an embodiment of an alloy keel structure of the present invention. As shown in the figure, the present invention provides an alloy keel structure, including a main keel body, the end of the main keel body is provided with an end wooden square 1, and the end wooden square 1 is larger than the end of the main keel body, so The main keel body includes two side supports 2 and a beam bottom 3. The two side supports 2 and the beam bottom 3 form a U-shaped structure. The beam bottom 3 is provided with a number of beam bottom holes 4, and a connecting belt is provided between the beam bottom holes 4 5. The connecting belt 5 is provided with a support wood 6 inside. The two sides of the support 2 and the be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com