Water seepage control construction method for karst water-rich geological underground structure waterproof construction

A technology of underground structure and construction method, which is applied in the direction of infrastructure engineering, protection devices, buildings, etc., can solve the problems of affecting waterproof construction and poor waterproof effect, and achieve the effect of improving the waterproof performance of structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

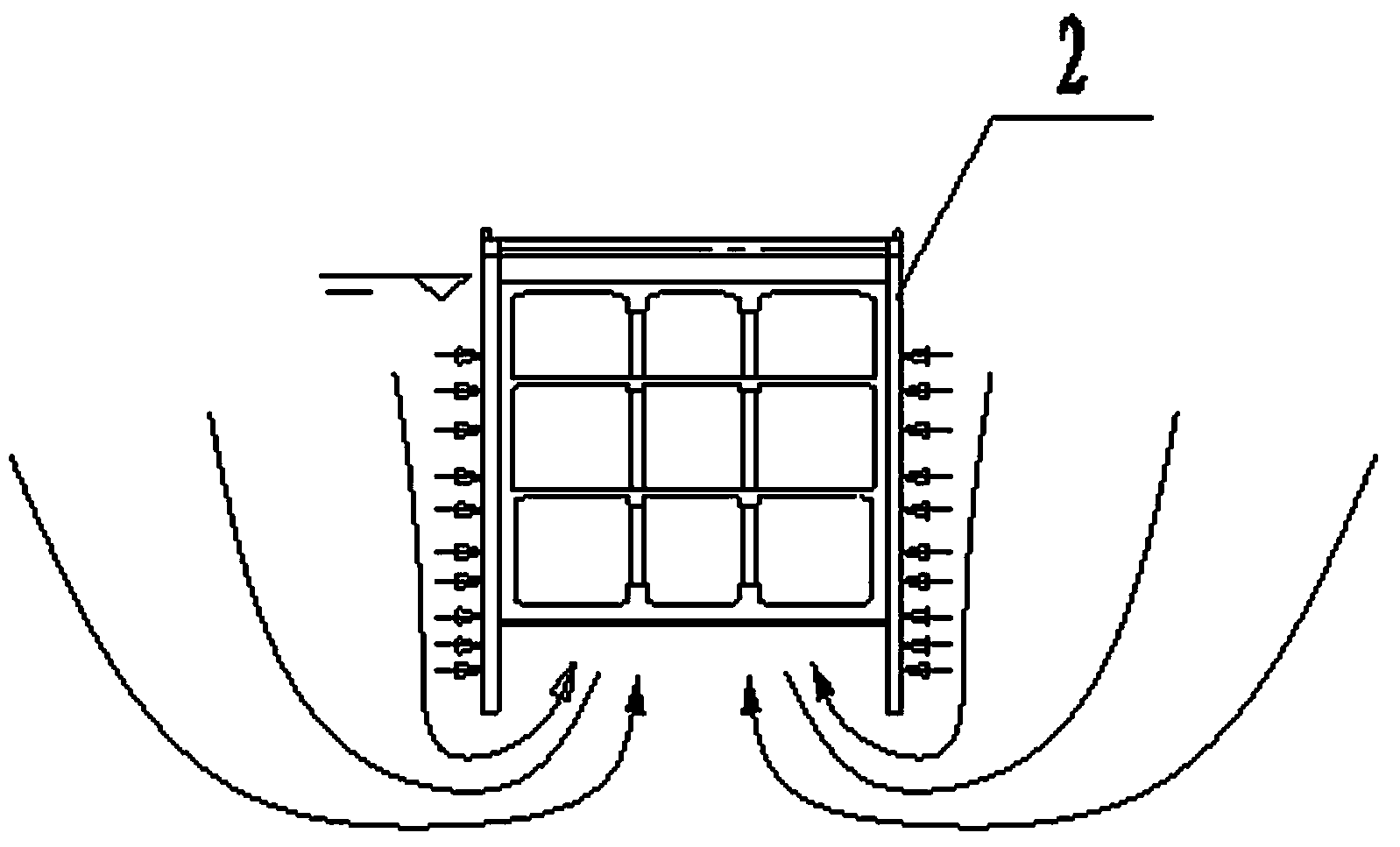

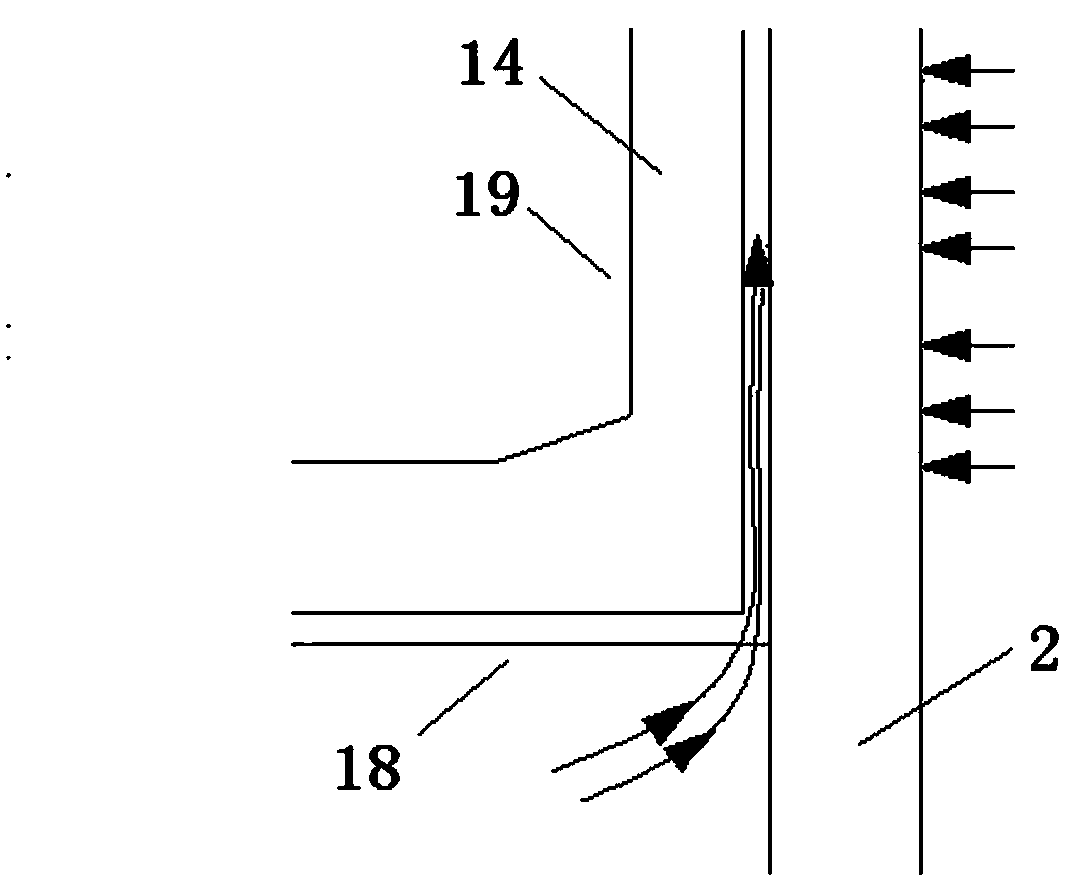

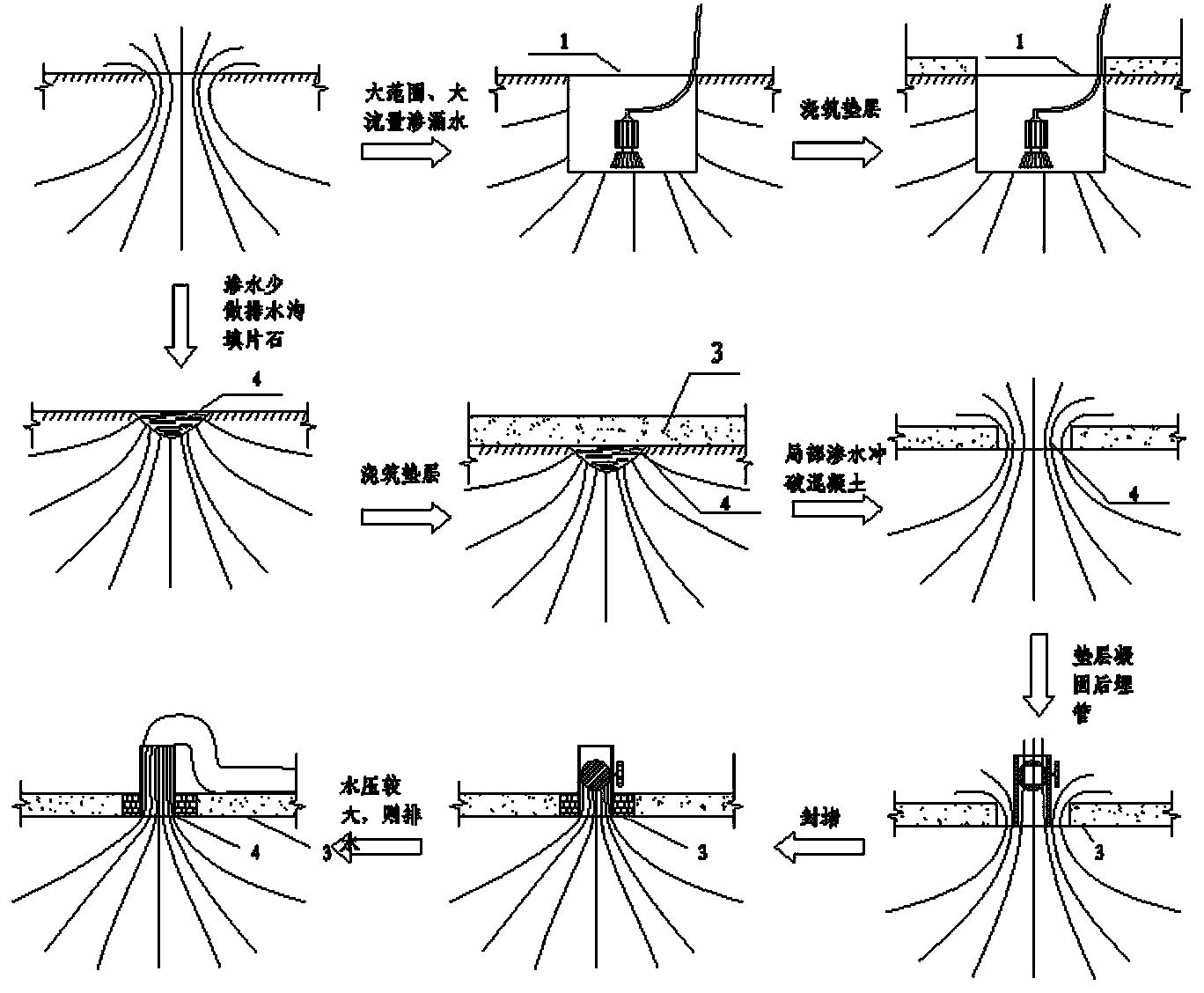

[0071] Wuyi Square Station is the station with the most complex geology, the largest engineering volume and the most strategic significance in Changsha Metro Line 2. The bedrock is moderately weathered limestone, with obvious corrosion phenomenon, well-developed karst caves of different sizes, and there is a large karst ditch with a depth of 104m in the middle of the right line of the station. Easy to disintegrate. The average water level of the station is 37.76m, the connectivity between the karst caves (dissolved gaps) at the bottom of the foundation pit is good, and the karst water has a large hydraulic connection with the pore water of the Quaternary loose rocks at the upper part, so the water at the bottom of the foundation pit is abundant, and It is pressure-bearing, and the designed water inflow of the foundation pit is 687.82m3 / d.

[0072] The underground station is designed according to the requirements of the first-class waterproof level, no water seepage is allowed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com