Clamping seat enclasping tile type lightning protection net and construction method thereof

A tile-embracing and lightning protection net technology, which is applied in the field of deck tile-embracing lightning protection nets, can solve problems such as roof leakage and tile damage, and achieve the effects of ensuring project quality and safety, advanced technology, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

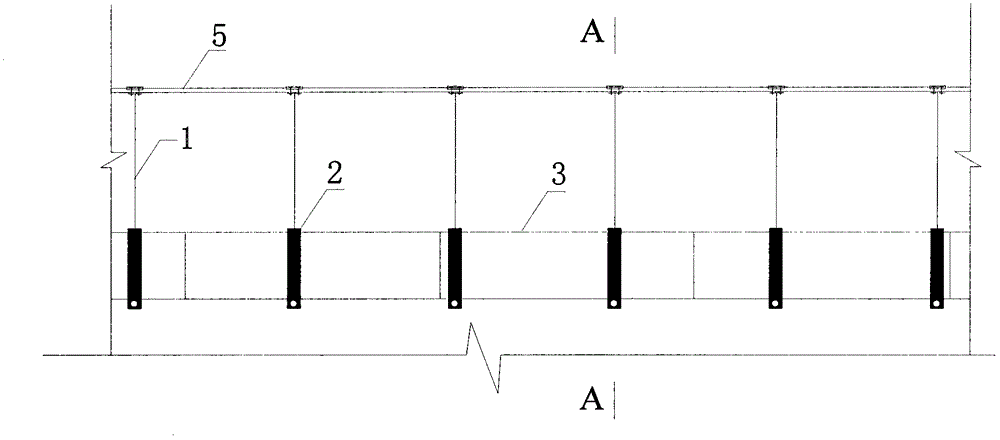

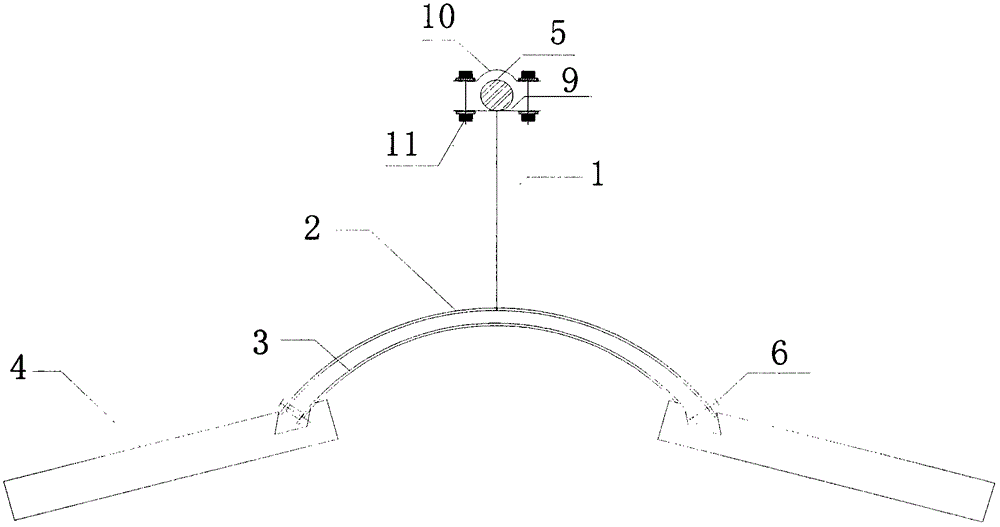

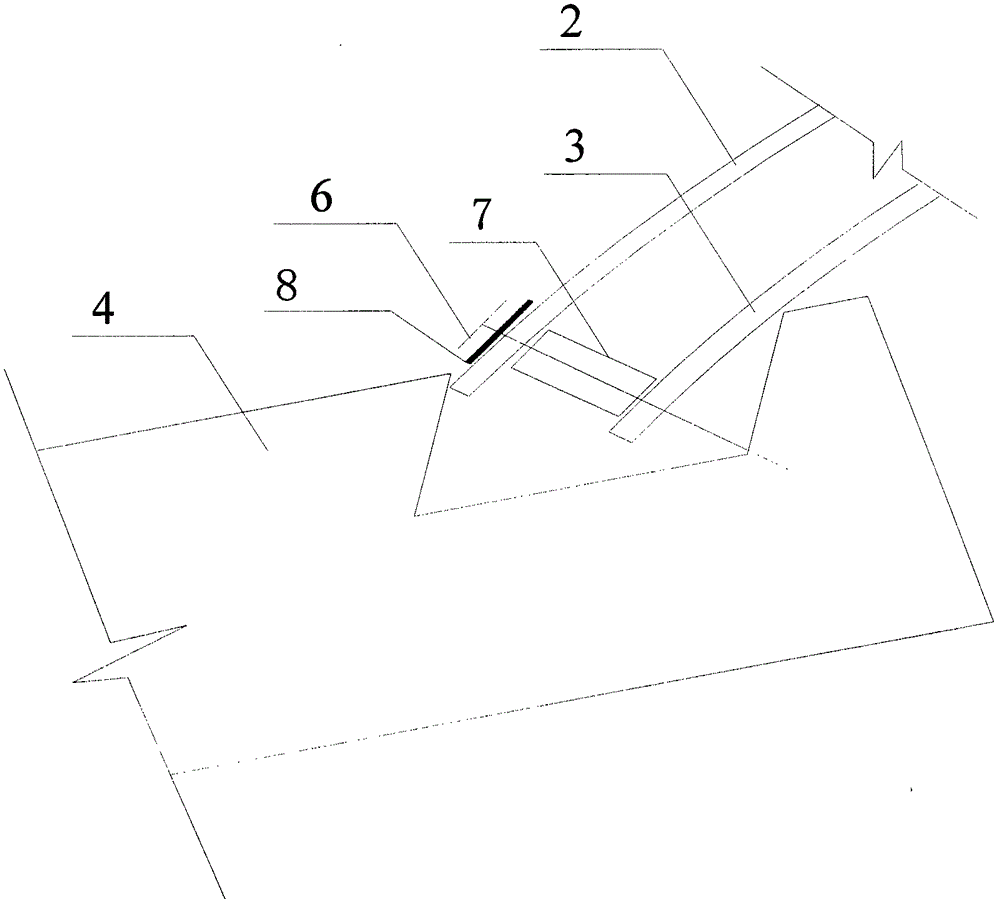

[0016] Holder tile type lightning protection net, including galvanized round steel 1, galvanized flat steel 2, buckle tile 3 and roof tile 4, lightning protection wire 5, galvanized screw rod 6, sealing rubber ring 7, galvanized gasket 8; The upper end of the galvanized round steel 1 is connected with a lightning protection wire 5; the galvanized flat steel 2 is in the shape of a long arc, and a plurality of them are arranged at intervals of one meter along the roof buckle 3, and the middle position of each galvanized flat steel 2 is connected with a The galvanized round steel 1 is provided with a saw cut at the position where the roof tile 4 connects with the buckle 3; holes are reserved at both ends of the galvanized flat steel 1 and the buckle 3, and the positions are symmetrical, and the buckle 3 and the galvanized flat steel 2 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com