Cable protection device

A technology of cable protection and protection device, applied in electrical components and other directions, can solve the problems of electric disconnection during construction, affecting the civilized construction image of the construction site, damage to the cable protective layer, etc., to improve safety, improve the level of civilized construction, and beautify the layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

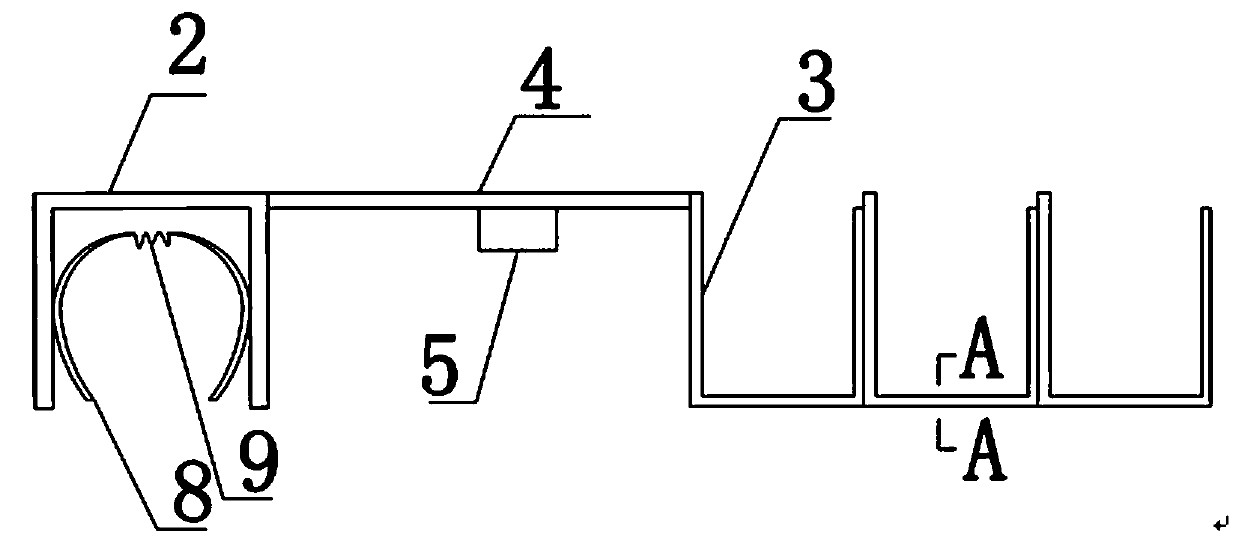

[0015] like figure 1 , figure 2 Among them, a cable protection device includes a hook, an electric leakage alarm device 5, and an insulating sheath 1 covered on the hook. The insulating sheath 1 is made of an insulating rubber or plastic hose. The hook includes a fixed opening with an opening downward. U-shaped groove 2, three cable U-shaped grooves 3 with upward openings, and elastic fixing clips are arranged in the U-shaped grooves fixing U-shaped groove 2, and the elastic fixing clips include two clamping arms 8, spring connectors 9, two clamping arms 8 are respectively movable and fixed on the inner wall of the fixed U-shaped groove 2, and the two ends of the spring connector 9 are respectively connected with a clamp arm 8, and the adjacent cable U-shaped groove 3 is directly fixed, and the fixed U-shaped groove 2 and the cable U-shaped groove 3 pass through The connecting rod 4 is connected; the connecting rod 4 can be stretched;

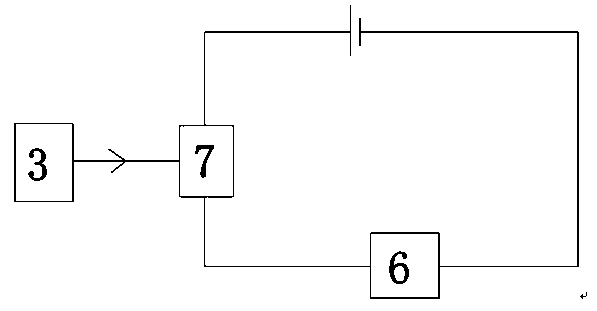

[0016] like image 3 , the leakage a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com