Method for hoisting terrace for furnace top raw gas pipeline

The technology of a crude gas pipeline and a hoisting method is applied in the field of hoisting a crude gas pipeline platform on the top of the furnace, which can solve the problems of insufficient lifting height and inability to install a release pipe, and achieve the effects of improving the safety level, improving the quality of installation and welding, and shortening the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

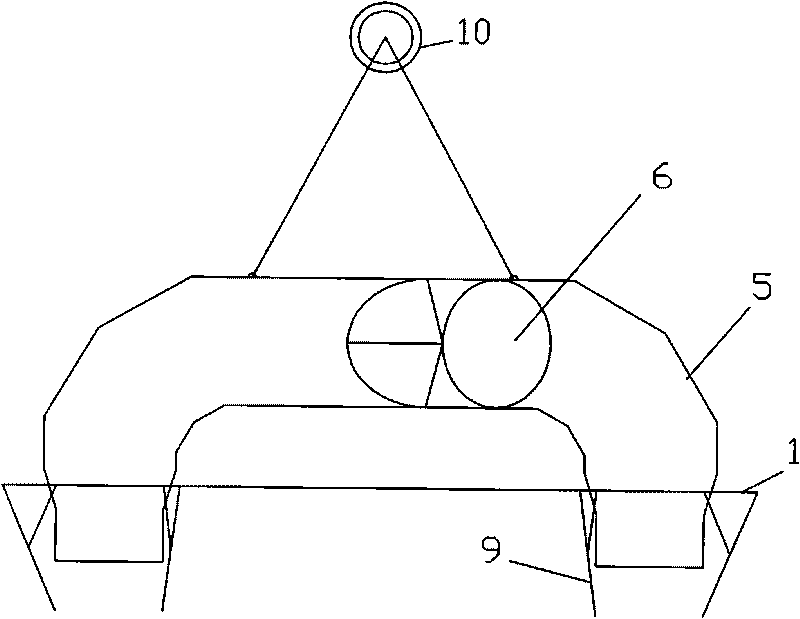

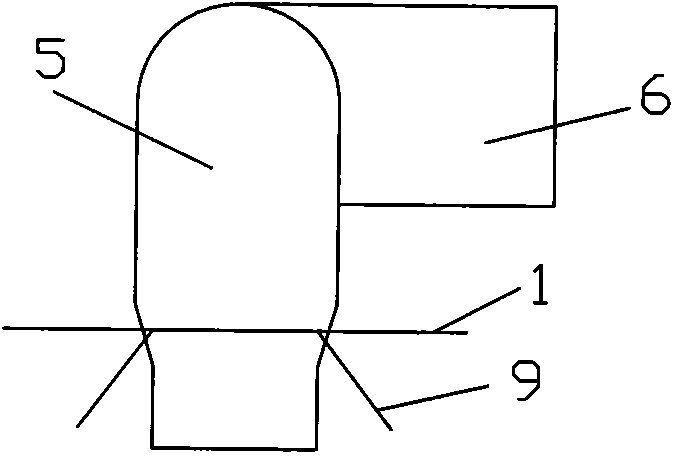

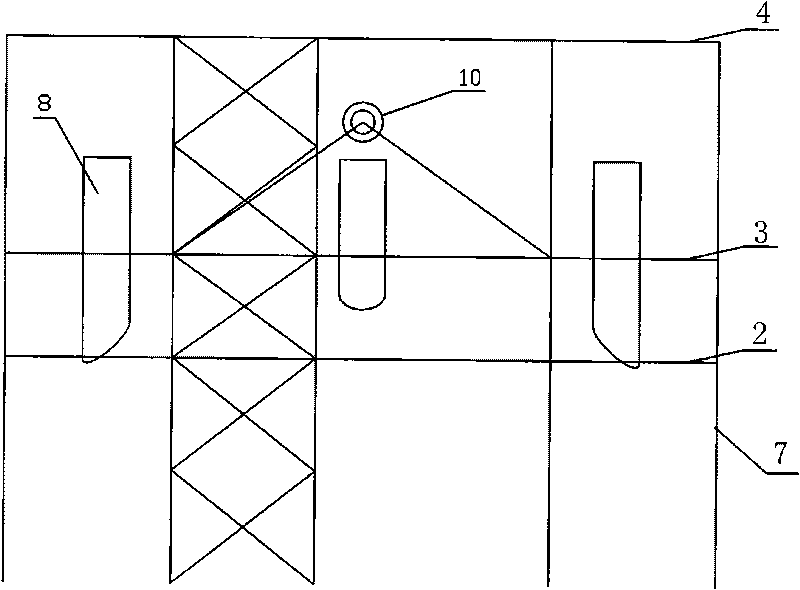

[0026] The method for hoisting the platform of the furnace top crude gas pipeline provided by the invention includes portable hoisting and integral interspersed hoisting. The platform has multiple layers, all of which are steel frame structures, and are connected as a whole. in:

[0027] Portable hoisting: used for the hoisting of the bottom platform, which is the first floor platform.

[0028] Before hoisting, make preparations, specifically: first assemble the riser and horizontal tubes, temporarily fix the horizontal tubes on the ground according to the installation form, install a tripod horizontal support on the relative installation elevation of the horizontal tubes, and set up a temporary Support to support the horizontal brace and the platform, and then directly install the first-floor platform on the horizontal brace, and weld all the components on the first-floor platform; then use the riser pipe horizontal tube seat fulcrum to set up a temporary tie rod to fix the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com