Single-layer three-dimensional prefabrication with excavation of foundation pit and assembly of sunken construction ladder and construction method

A climbing ladder and single-layer technology, which is applied in the field of single-layer three-dimensional prefabrication and submerged construction ladders with foundation pit excavation, can solve the problems of low rigidity, difficulty in adapting to the construction speed, and potential safety hazards, so as to speed up construction progress, improving the level of civilized construction, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

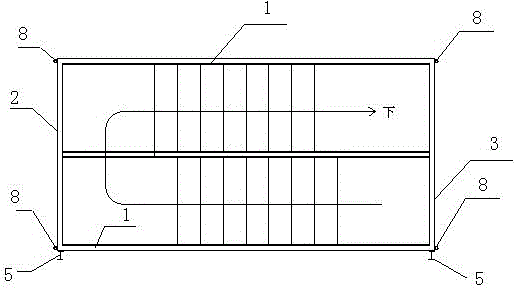

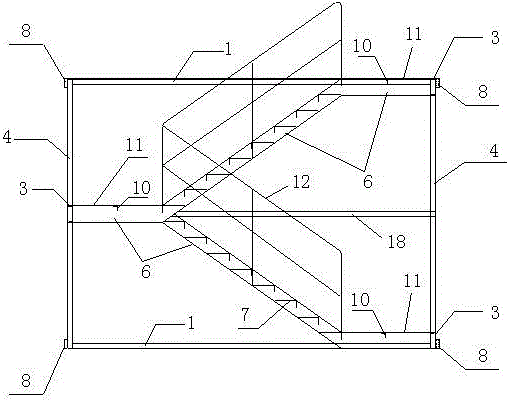

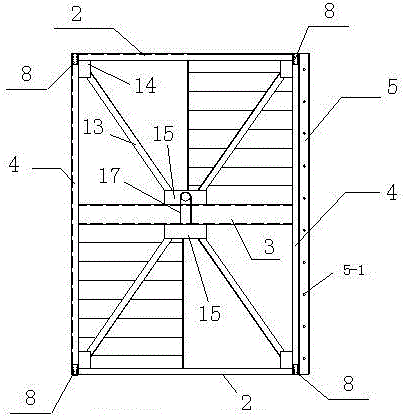

[0043] like Figure 1 to Figure 11 As shown, a single-layer three-dimensional prefabricated submerged construction ladder is assembled with the excavation of the foundation pit. The connection structure includes the following components: It is assembled from a single-layer three-dimensional ladder, a vertical stabilizing mechanism and a stable sinking mechanism.

[0044] like Figure 1 ~ Figure 4 As shown, the main structure of the ladder is composed of multiple single-layer three-dimensional steel ladder prefabricated components, which are connected and assembled into a multi-layer integral ladder with connecting pipes 8 and inner bolts 9 located at the four corners of the side elevation of the steel ladder, as shown in Figure 10 , Figure 11 shown.

[0045] like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com