Assembled dry floor heating system

A prefabricated and floor heating technology, which is applied in hot water central heating systems, heating systems, heating methods, etc., can solve the problems that cannot meet the needs of prefabricated building decoration, etc., achieve remarkable upward heat conduction effect, convenient installation, and guaranteed quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

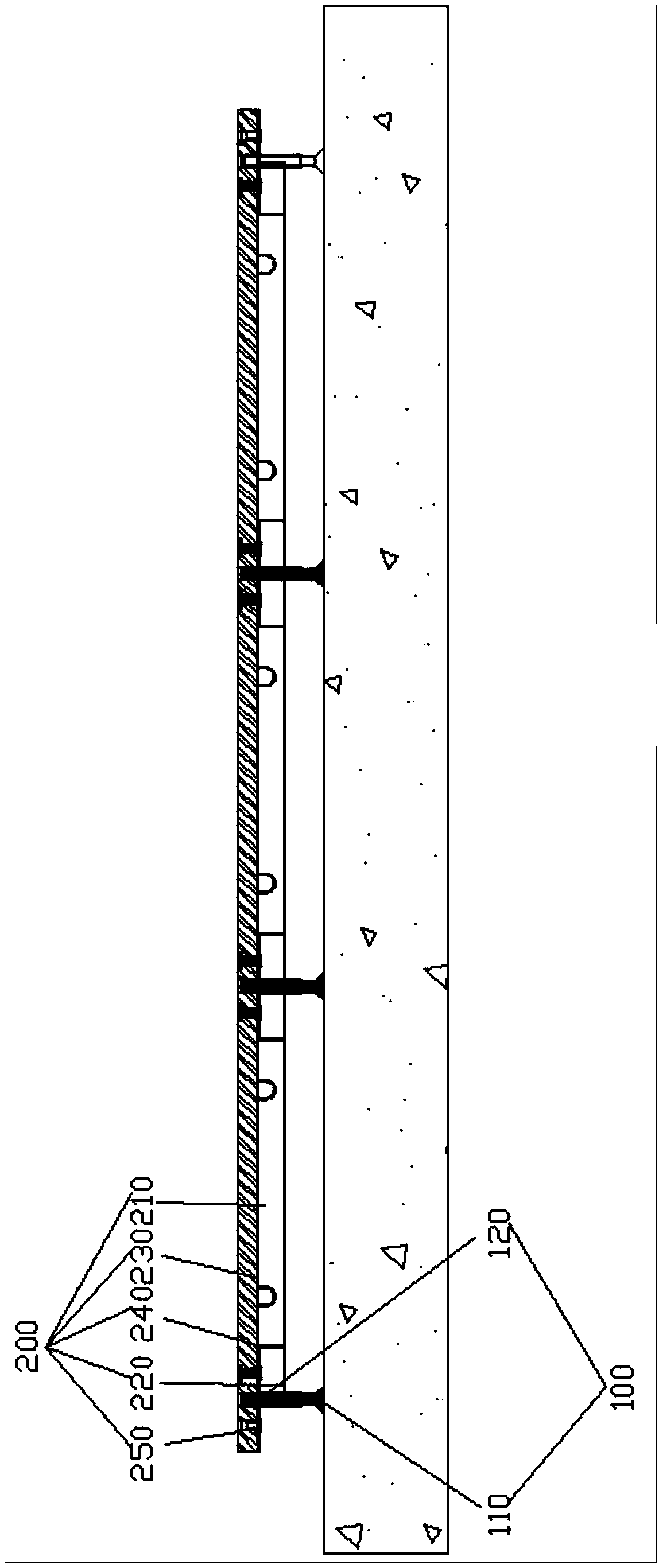

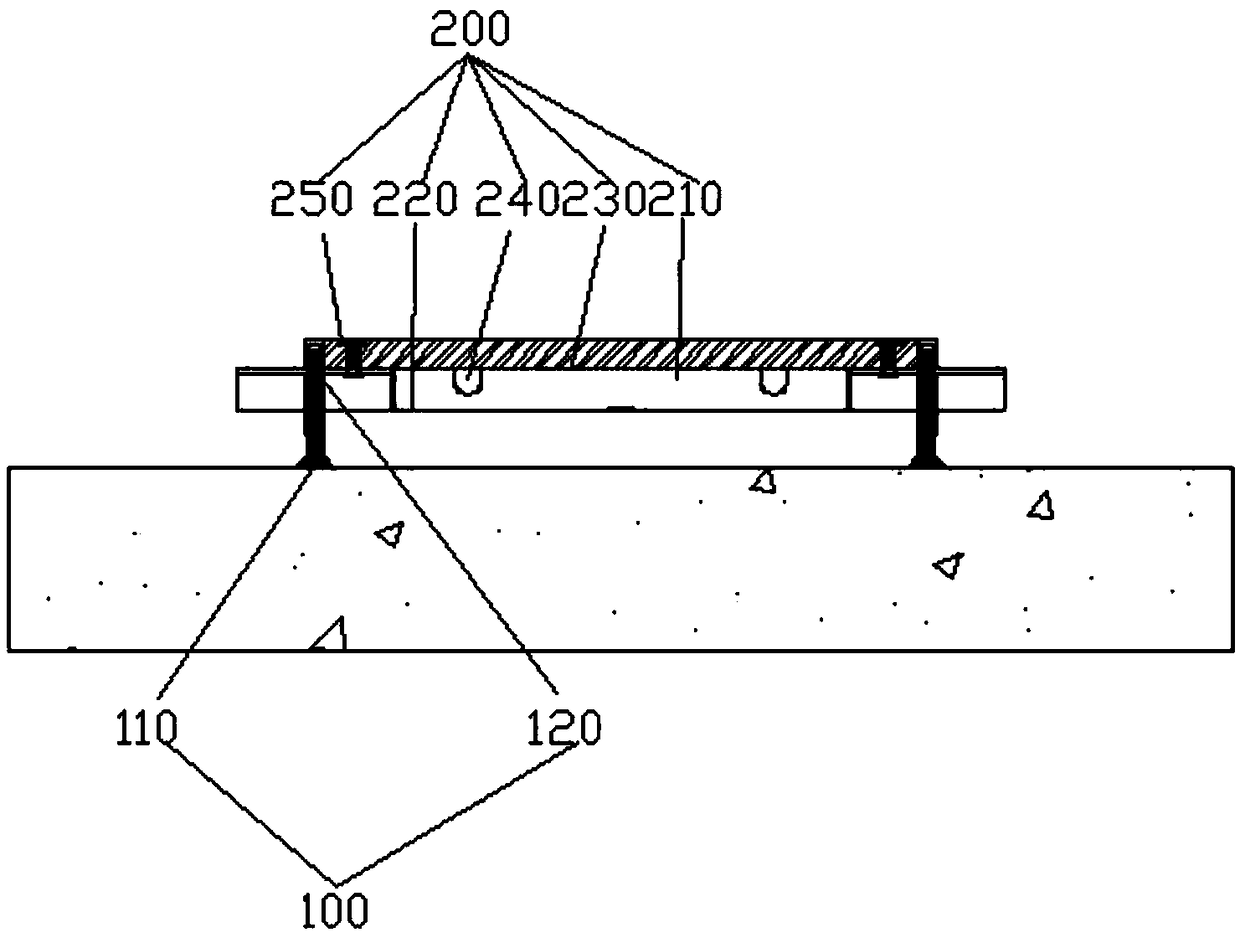

[0032] Figure 1A It is a longitudinal sectional structure diagram of the present invention. Figure 1B for Figure 1A A partial enlargement of the . Such as Figure 1A and Figure 1B As shown, an assembled dry floor heating system includes: a support 100 and a floor heating module 200, and the support 100 and the floor heating module 200 are fixedly connected.

[0033] Figure 1A The middle triangle level represents the reinforced concrete floor slab.

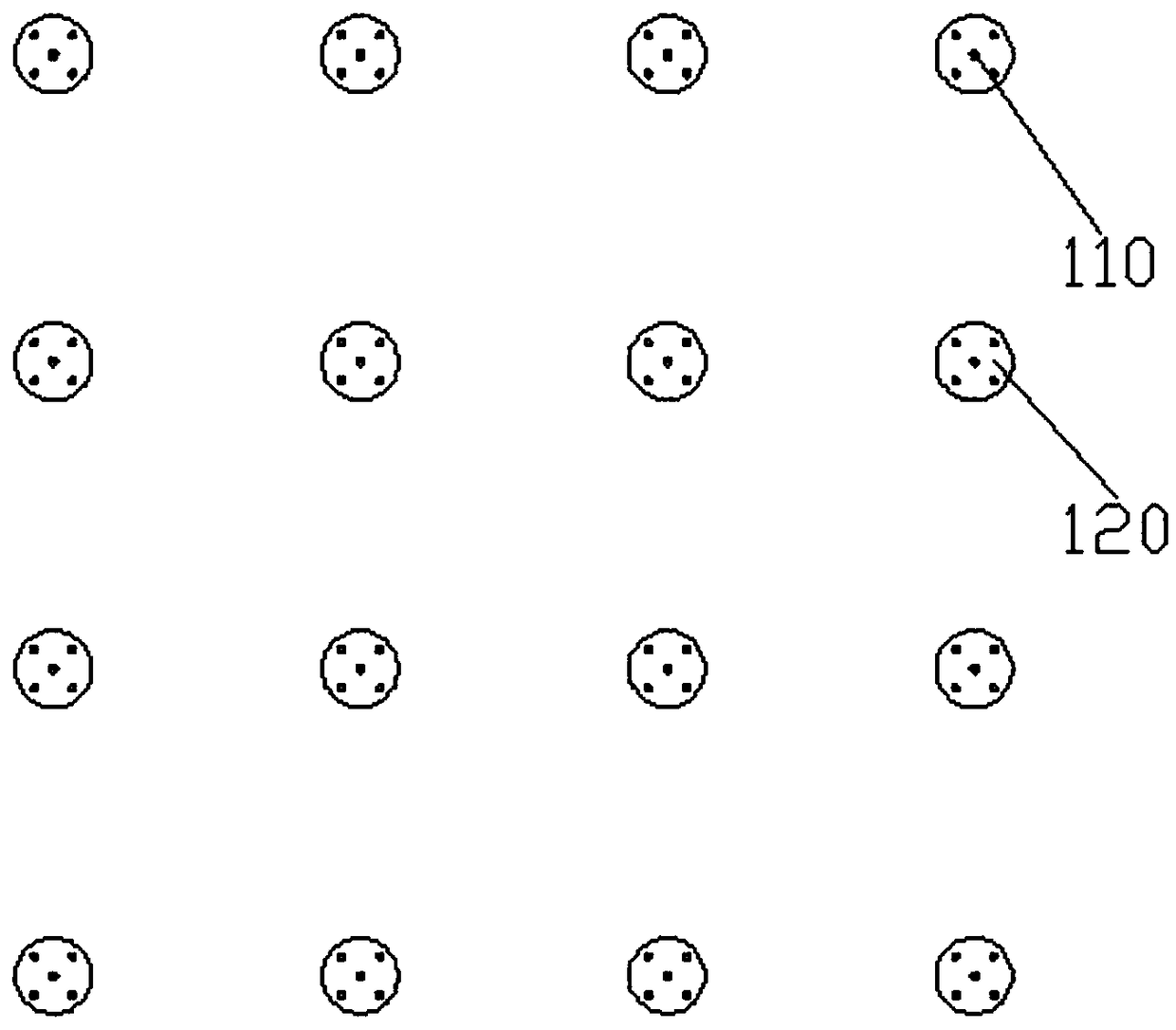

[0034] Such as Figure 1A and Figure 1B As shown, the supporting member 100 includes: an adjustable screw rod 110 and a circular limiting bracket 120 .

[0035] The circular limit bracket 120 is installed on the adjustable screw rod 110, when the height of the circular limit bracket 120 is adjusted by the slot on the top of the adjustable screw rod 110, the adjustable screw rod 110 is rotated. The screw rod and the bottom support steel sheet are flexibly connected, so that the adjustable screw rod 110 can be twisted easil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com