Prefabricated indoor dry hanging type wall brick and construction method thereof

A construction method and prefabricated technology, which is applied in covering/lining, construction, building construction, etc., can solve the problems that cannot meet the needs of prefabricated building decoration, etc., and achieve simple manufacturing process, excellent mechanical performance and good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

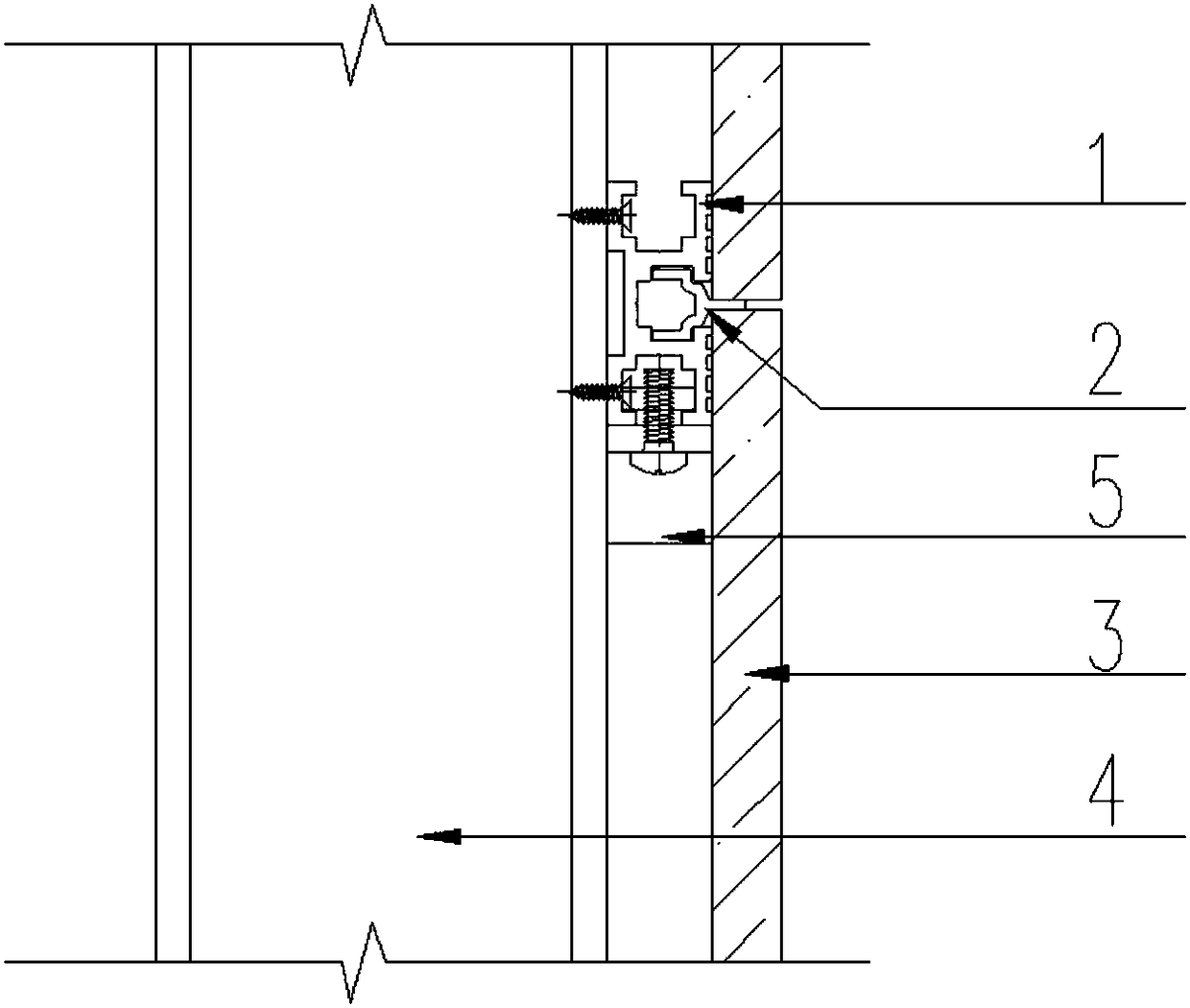

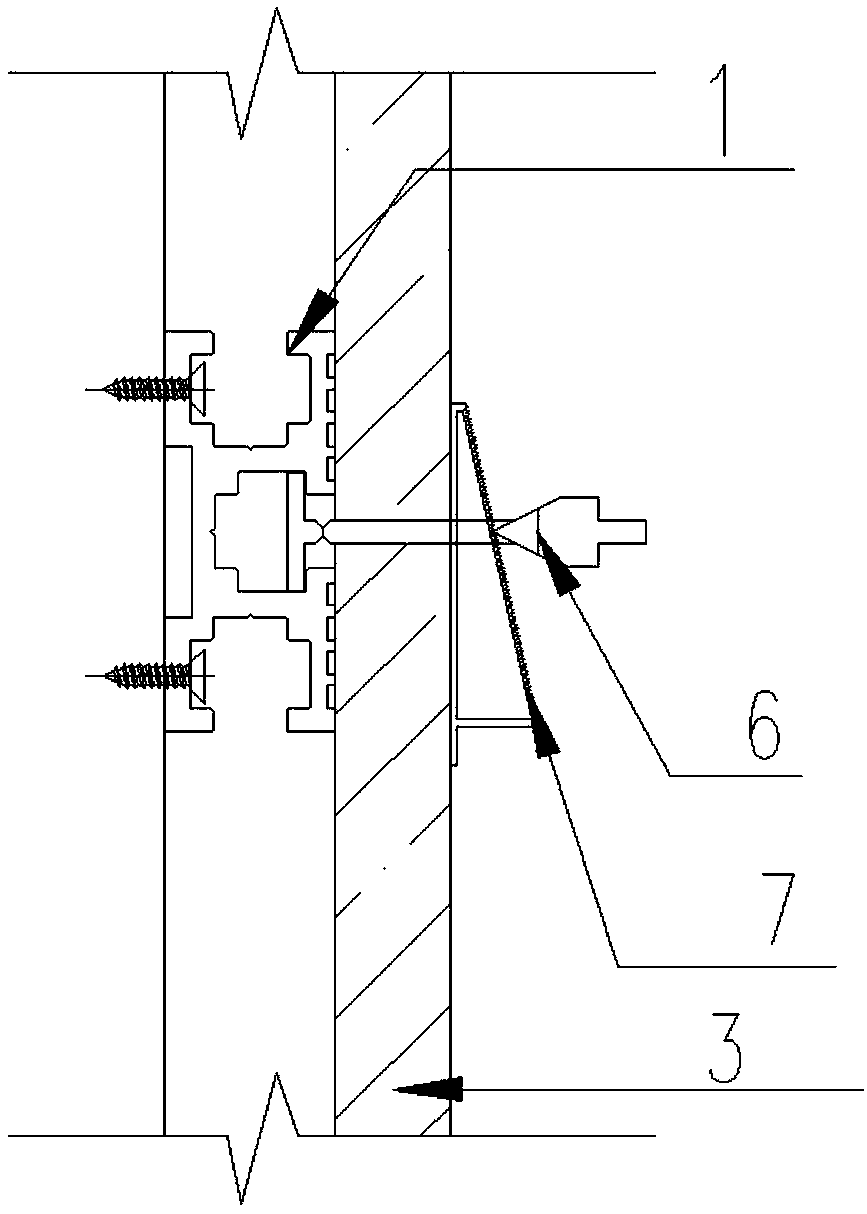

[0051] Such as figure 1 and figure 2 As shown, a prefabricated indoor dry-hanging wall brick system includes: a frame joist 1, a support bar 2, a wall brick 3, a light steel joist 4, a tie bar 6, and a leveler cap 7.

[0052] The light steel keel is fixed on the partition wall or civil wall;

[0053] The frame keel is detachably connected and fixed on the light steel keel; the bracket is detachably connected and fixed on the frame keel; and the structural glue is applied, and the wall brick (3) is dragged by the bracket and then bonded to the frame keel Top; the tie rods are put into two vertical wall bricks; the leveler cap is set as a wedge-shaped structure, wedged between the vertical joints of the tie rods pre-embedded in the wall bricks, and the tie rods are tightened.

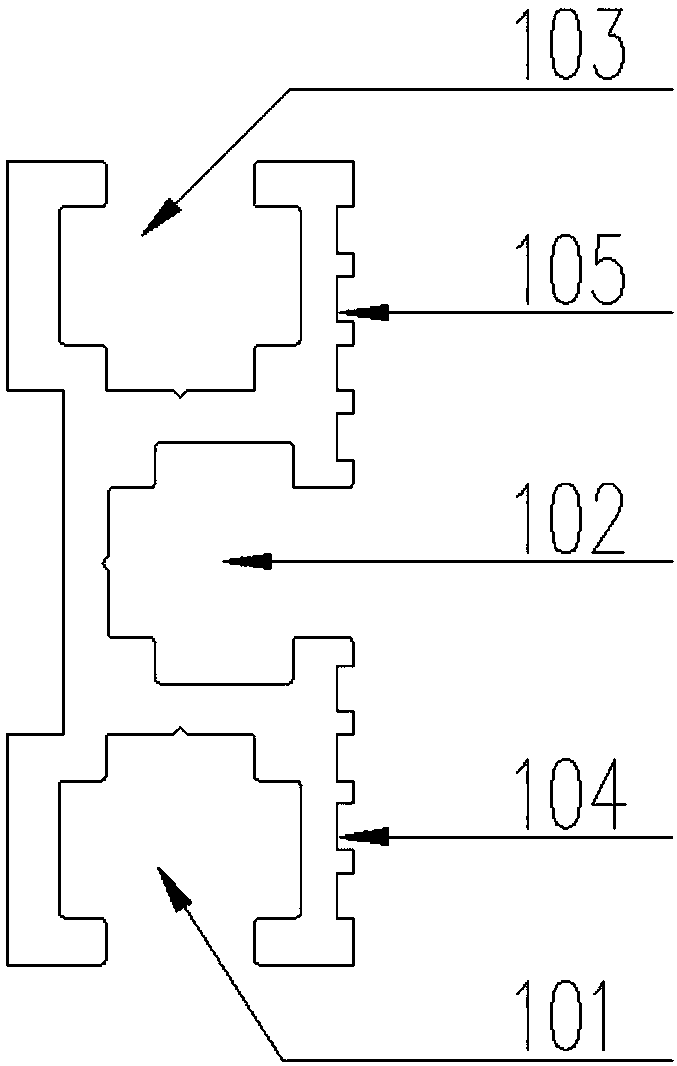

[0054] Refer to the functional design of frame keel and bracket shape and notch image 3 and Figure 4 .

[0055] Such as image 3 As shown, the section of the frame keel 1 is set as a "mouth" shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com