Prefabricated rapidly-assembled enclosing wall structure and construction method

A fence and fast technology, applied in the direction of basic structure engineering, fences, building types, etc., can solve the problems of easy cracking and dislocation of prefabricated fence walls, easy cracking structural strength, and unstable connections, etc., to improve prefabrication efficiency and anti-corrosion Strong overturning ability and convenient construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A prefabricated and quickly assembled wall structure, such as Figure 7 As shown, it includes a prefabricated concrete foundation 2 at the bottom, a prefabricated wall panel 1 fixed on the prefabricated concrete foundation 2 , and a topping 3 fixed on the top of the prefabricated wall panel 1 .

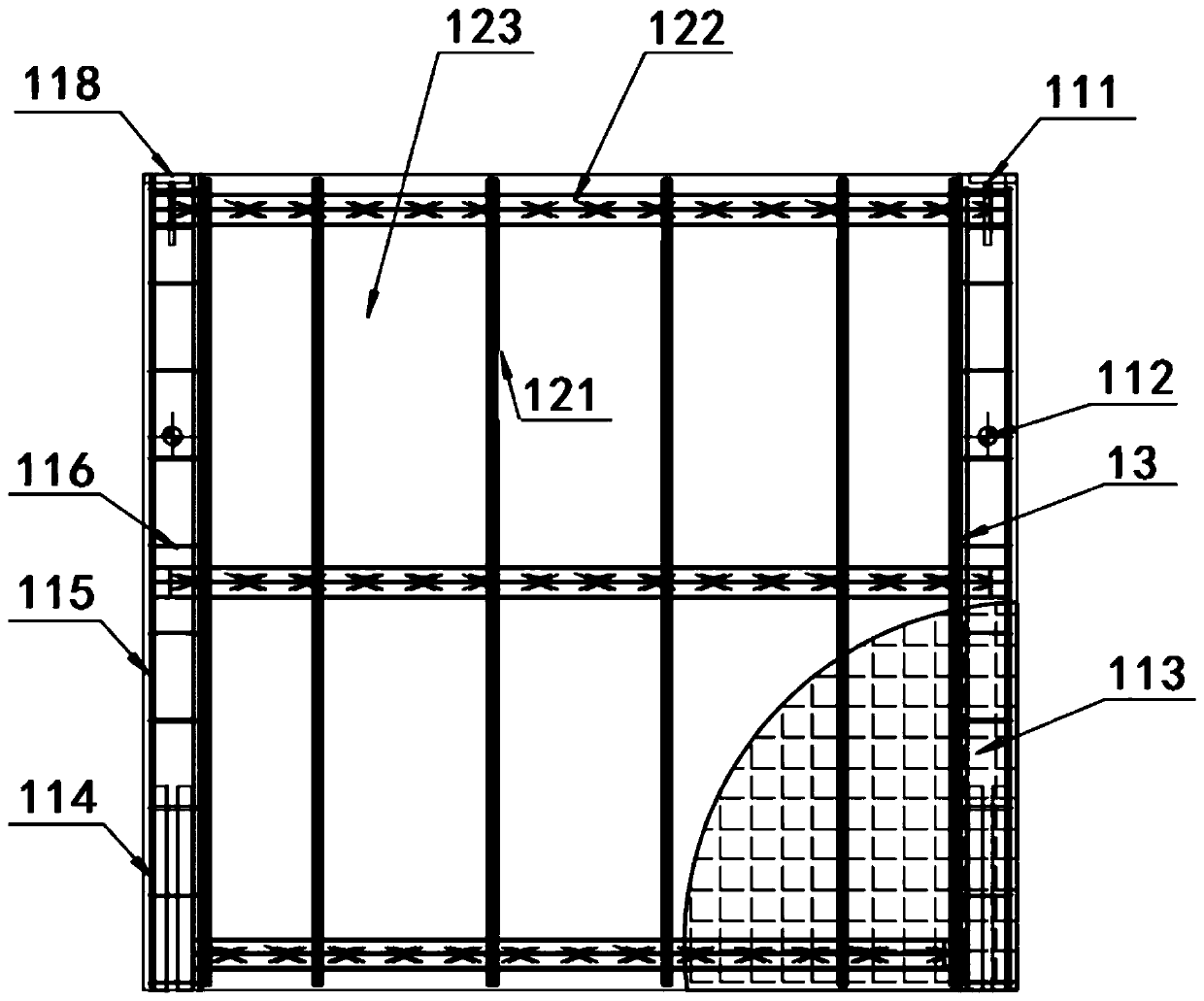

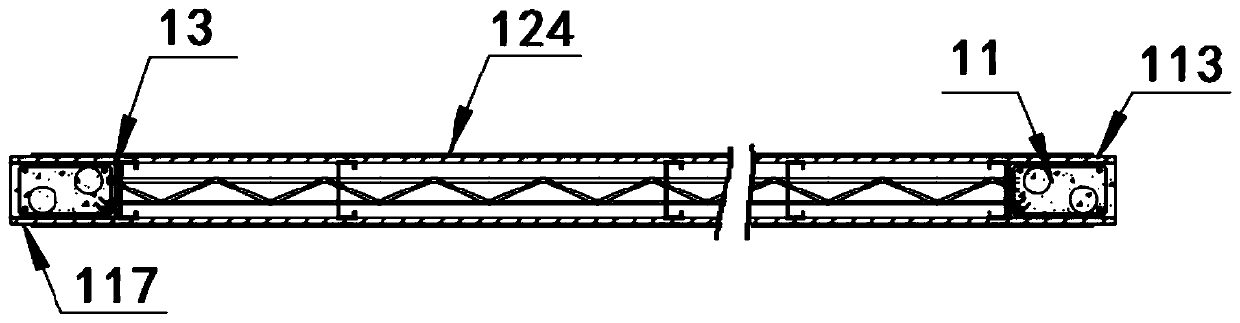

[0059] Such as figure 1 with 2 As shown, the prefabricated wall panel 1 mainly includes two parts, the end column 11 and the foamed concrete wall 12 .

[0060] to combine figure 1 It can be seen that the end column 11 adopts a concrete structure as the main force-bearing member, and the end column 11 is equipped with several vertical longitudinal bars 115 and stirrups 116 . In order to make the production simple and specific, it is also possible to adopt row frame steel bars to replace the steel bar skeleton composed of longitudinal bars 115 and stirrup bars 116 . In order to facilitate the installation of the oblique support 4 , an internally threaded sleeve embedded part ...

Embodiment 2

[0083] In the use of temporary building walls, it is preferable to use bolt connection instead of grouting to connect the lower part of the wall, so that the wall panel 1 can be reused.

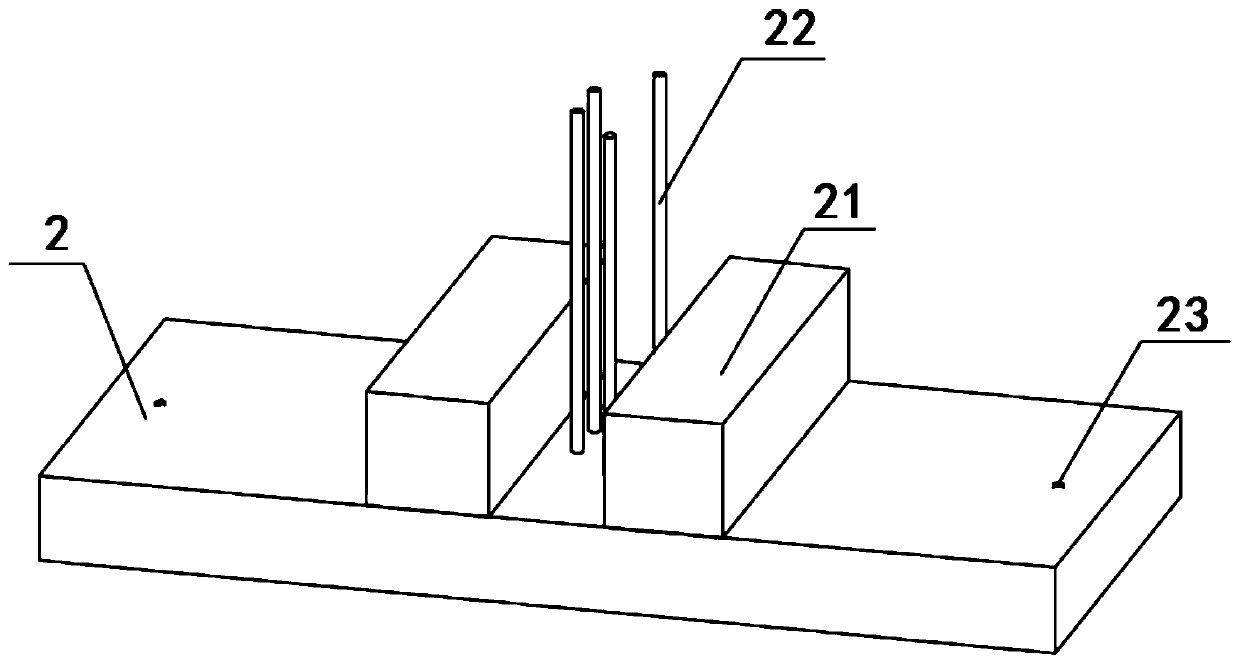

[0084] Such as Figure 8 As shown, this method is to pre-embed a steel box 25 and a pre-embedded pipe leading into the steel box 25 on the end column 11 of the wall panel 1, and the pre-embedded ribs 22 on the foundation 2 extend into the steel box 25 of the end column 11 Inside, the protruding end of the rib 22 is provided with a threaded section, and the threaded section stretches into the steel box 25 and is fastened by a bolt 26 . After fastening, the steel box 25 is filled with flexible mortar 27 . The gap between wall panel 1, foundation 2 and stopper 21 is filled with materials such as mortar 51 which are convenient to chisel out.

[0085] The rest of the structure is the same as that of Embodiment 1 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com