Steel structure floor slab assembly type process

A prefabricated, steel structure technology, applied in floors, building components, building structures, etc., can solve the problems of high cost of thermal insulation measures, long construction period, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

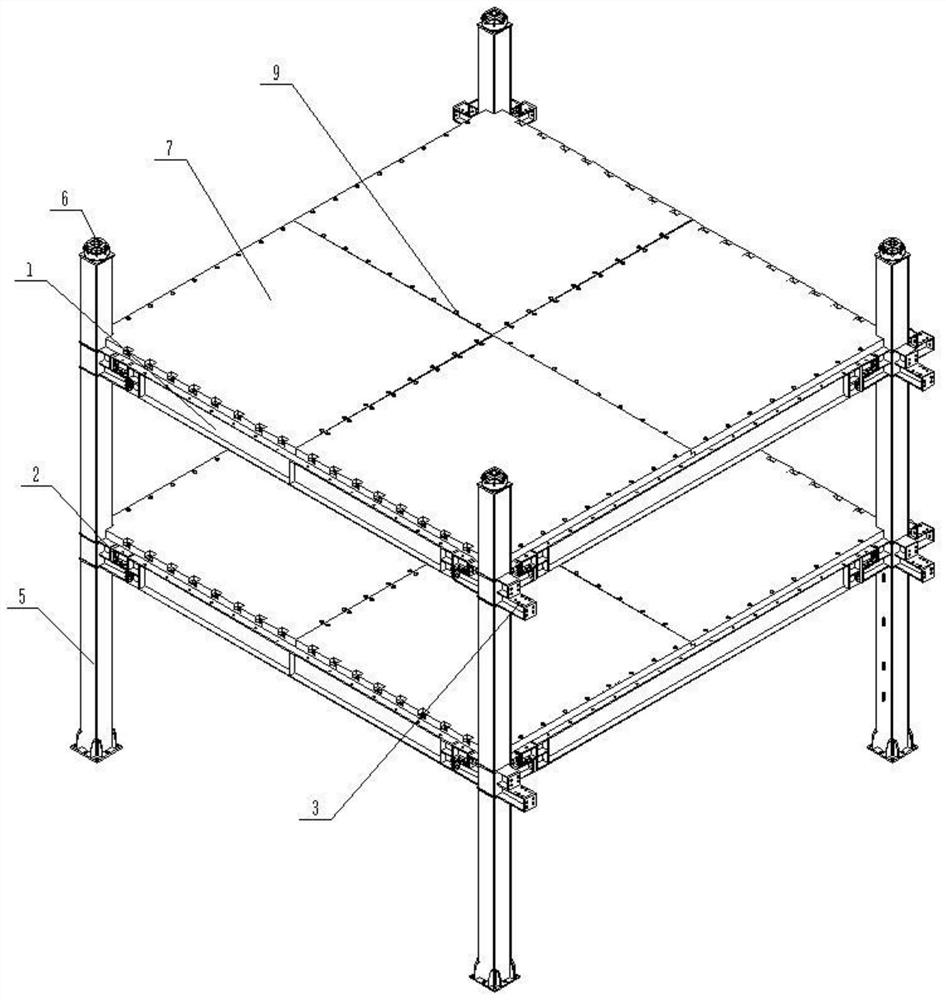

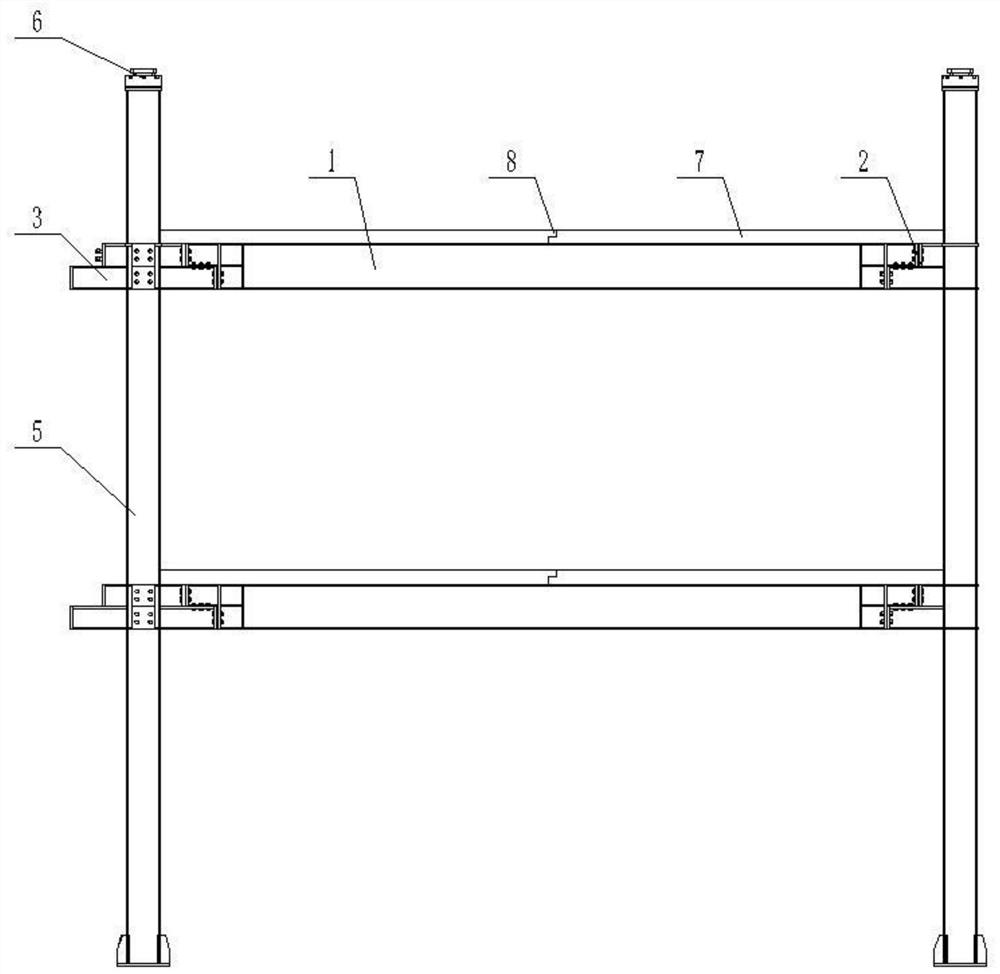

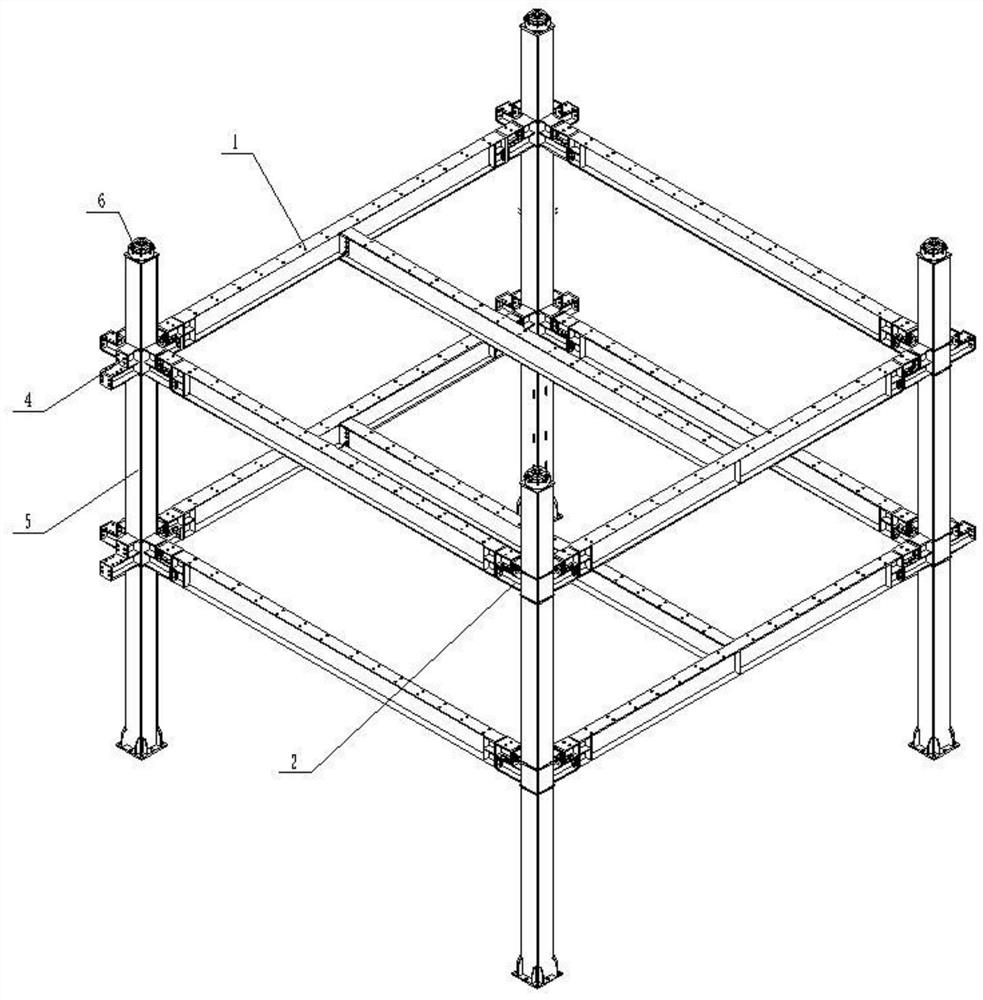

[0041] Such as Figure 1 to Figure 15 Shown, a kind of steel structure floor assembling type technique of the present invention is implemented according to the following steps:

[0042] In the first step, before the floor is installed, the beam 1 and column components are in place;

[0043] Assembling the column 5 and the beam 1 through each node structure into a main beam frame unit;

[0044] In the second step, the beam 1 reserves bolt holes according to the floor structure;

[0045] Connect the two ends of beam 1 with the corresponding node structure;

[0046] The third step is to place the floor plate body 7 on the beam;

[0047] The floor slab bodies 7 are correspondingly laid on the horizontal frame of the main beam frame unit, and the adjacent floor slab bodies 7 are overlapped and fixed;

[0048] In the fourth step, the floor slab body 7 is aligned with the bolt holes reserved in the beam, and connected through bolts;

[0049] The side of the floor board body 7 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com