Energy dissipation supporting structure, energy dissipation supporting frame system and construction method of energy dissipation supporting frame system

An energy-dissipating support and frame system technology, applied in building components, building structures, and earthquake resistance, can solve the problems of building structure damage, earthquake energy dissipation, and poor earthquake resistance, so as to absorb vibration energy, improve structural rigidity, The effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

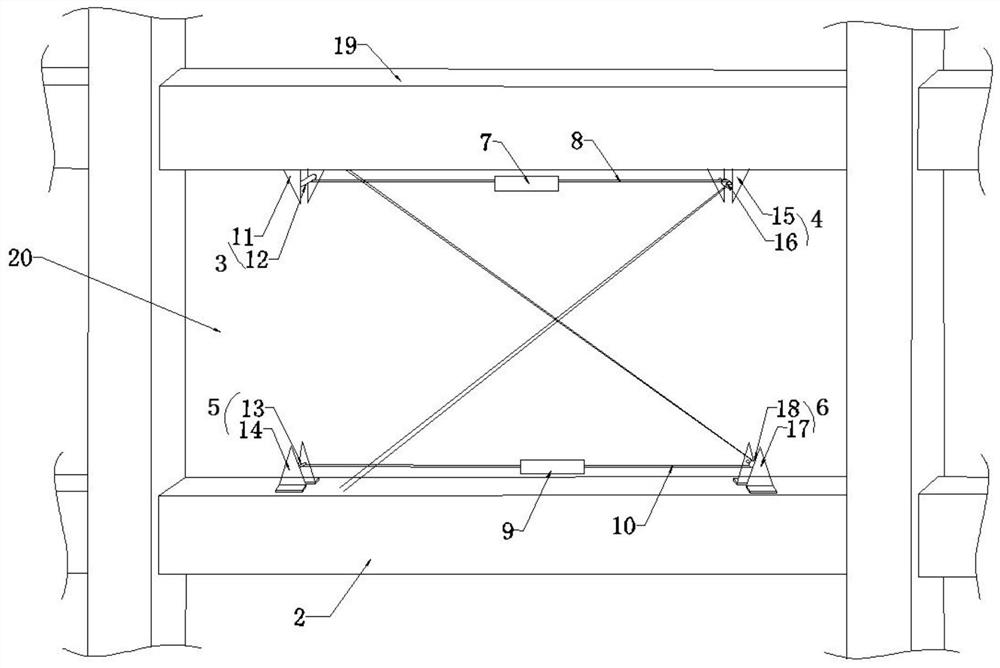

[0046] Please refer to figure 1 An energy-dissipating support structure provided for this application is installed in a frame unit 20. The frame unit 20 includes two prefabricated beams, namely an upper prefabricated beam 1 located relatively above and a lower prefabricated beam 2 located relatively below. The energy-dissipating support structure includes a support assembly; the support assembly includes: a first fixing member 3 installed at the bottom of the upper precast beam 1, a first steering member 4, and a second fixing member installed at the top of the lower precast beam 2 The fixing part 5, the second steering part 6;

[0047] A first energy dissipation device 7 is provided between the first fixing member 3 and the first steering member 4, and a first steel strand 8 is connected to both ends of the first energy dissipation device 7, and the first steel strand One free end of the wire 8 is connected to the first fixing member 3, and the other free end of the first st...

Embodiment 2

[0069] Such as Figure 4 Shown is an energy-dissipating support frame system provided by this embodiment, including the energy-dissipating support structure described above, and a support frame 19 formed by a plurality of prefabricated columns and a plurality of prefabricated beams; the support frame 19 has a plurality of frame units 20, and the energy dissipation support structure is installed in the frame units 20;

[0070] The prefabricated column includes a square steel pipe 21 and a diaphragm 22 installed in the square steel pipe 21, a column longitudinal reinforcement 23; the diaphragm 22 is provided with a pouring hole 24 and is used to install the column longitudinal reinforcement 23 The mounting hole 25;

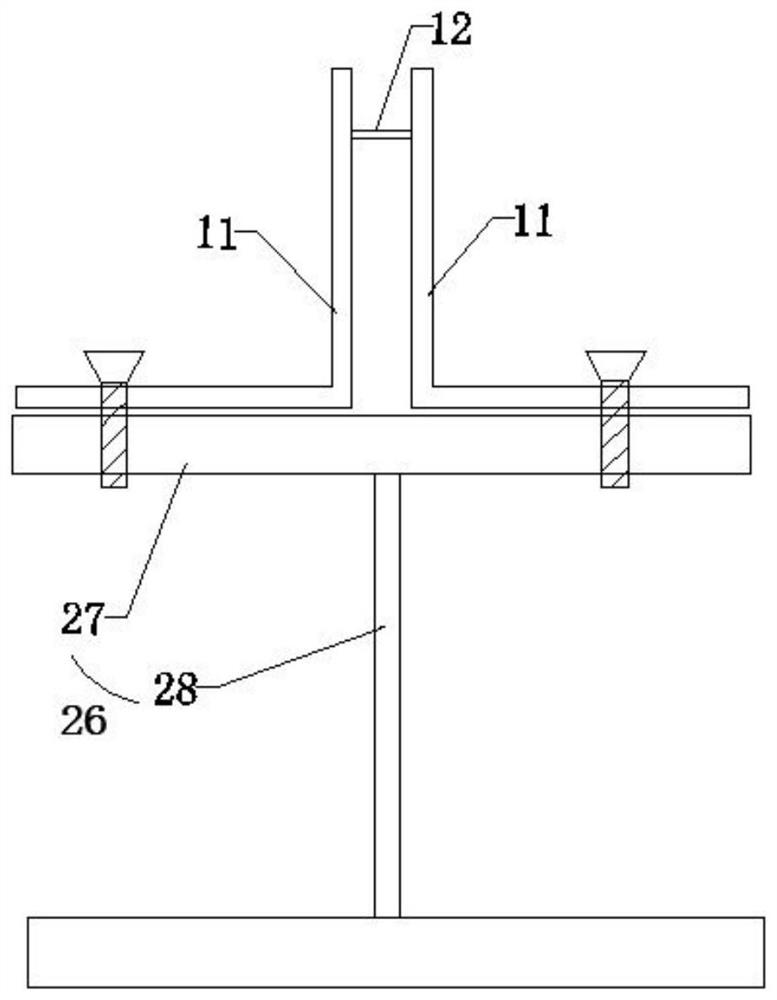

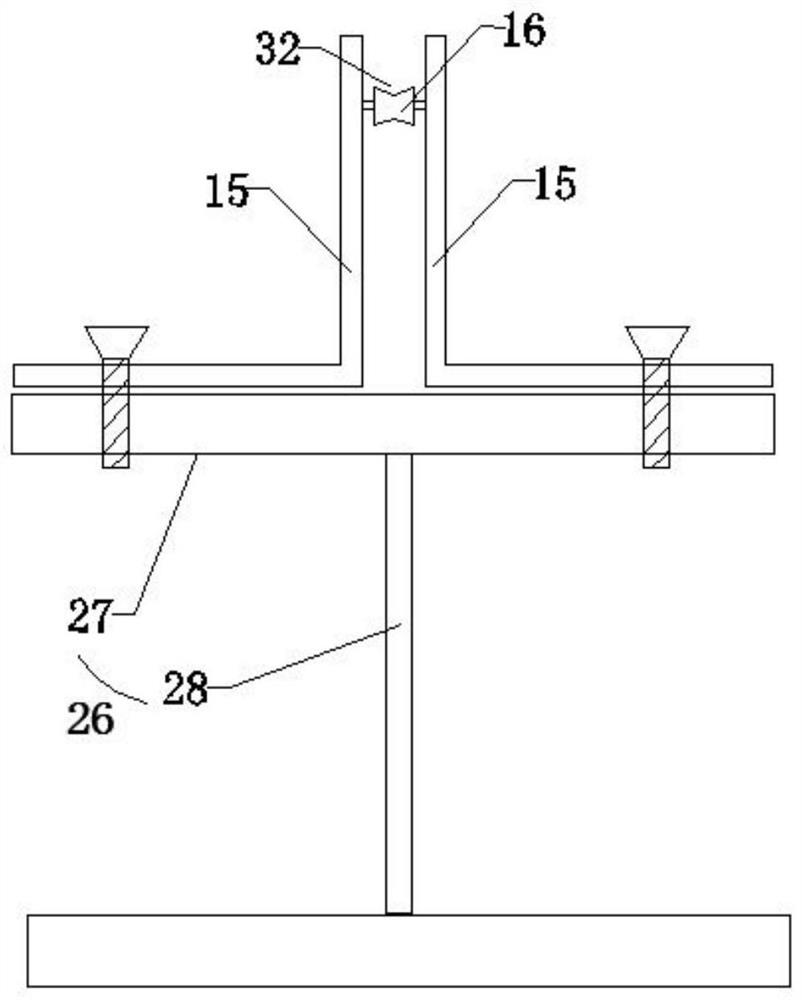

[0071] The prefabricated beam includes an I-beam 26 and beam longitudinal bars 31 welded on the I-beam 26; the I-beam 26 is exposed at both ends of the prefabricated beam;

[0072] The flange 27 of the I-beam 26 is welded to the side wall of the square steel pipe ...

Embodiment 3

[0082] Such as Figure 7 Shown is the construction method of the energy-dissipating support frame system described in the above structure provided by this embodiment, including the following steps:

[0083] Step S1: the factory manufactures the prefabricated columns and beams;

[0084] When making the prefabricated column, the installation hole 25 and the pouring hole 24 are drilled on the diaphragm 22; the diaphragm 22 is arranged in the square steel pipe 21; 23 passing through the installation hole 25, and binding with stirrups; pouring is performed after the binding is completed, so that the concrete passes through the pouring hole 24 and is compacted in the column, and the prefabricated column is obtained after curing;

[0085] When making the prefabricated beam, the beam longitudinal reinforcement 31 is welded on the I-beam 26 and bound with stirrups; The bolt holes 30 are opened on the web 28; concrete is poured and cured to obtain a prefabricated beam.

[0086] Step S2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com