Frame inclined energy dissipation supporting device

An energy-consuming support and frame technology, which is applied to building components, building structures, and earthquake resistance, can solve the problems of unfavorable replacement of damaged parts, unfavorable building reinforcement, and aggravation of earthquake disasters, so as to achieve easy repair, convenient reinforcement, The effect of improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

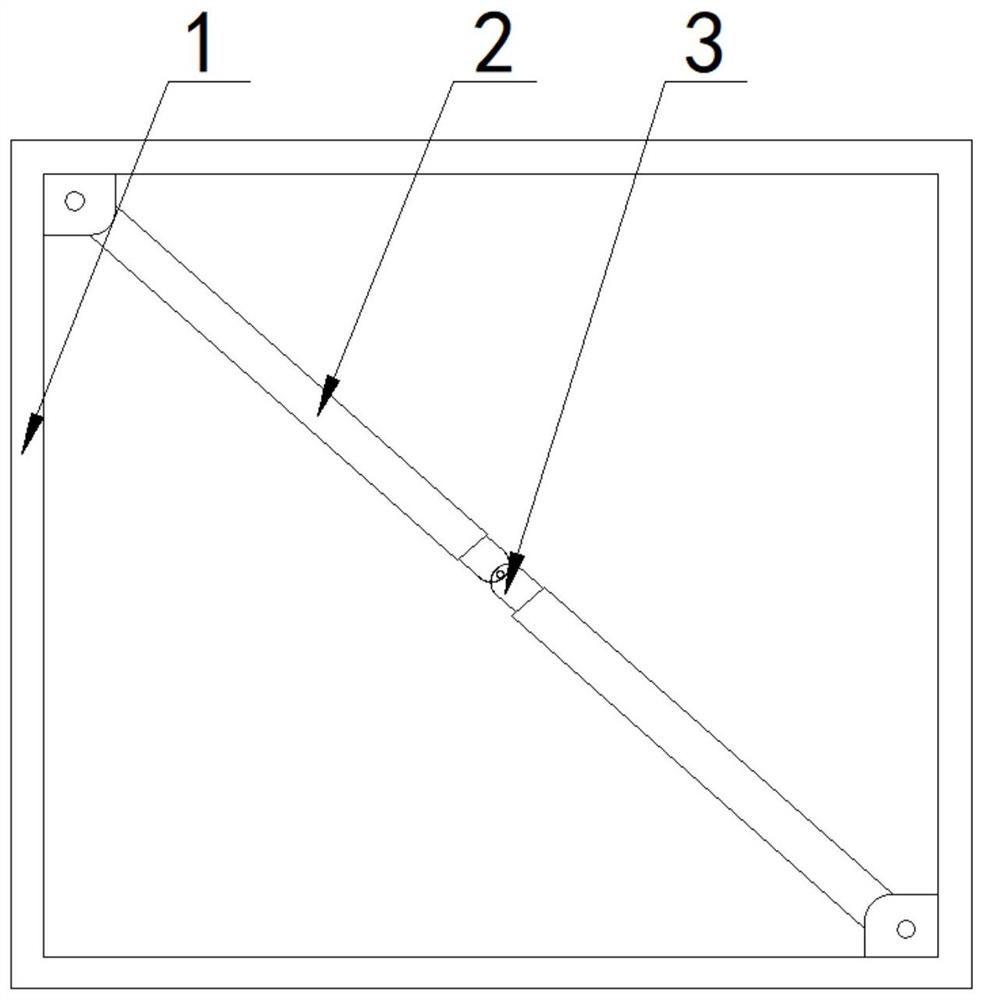

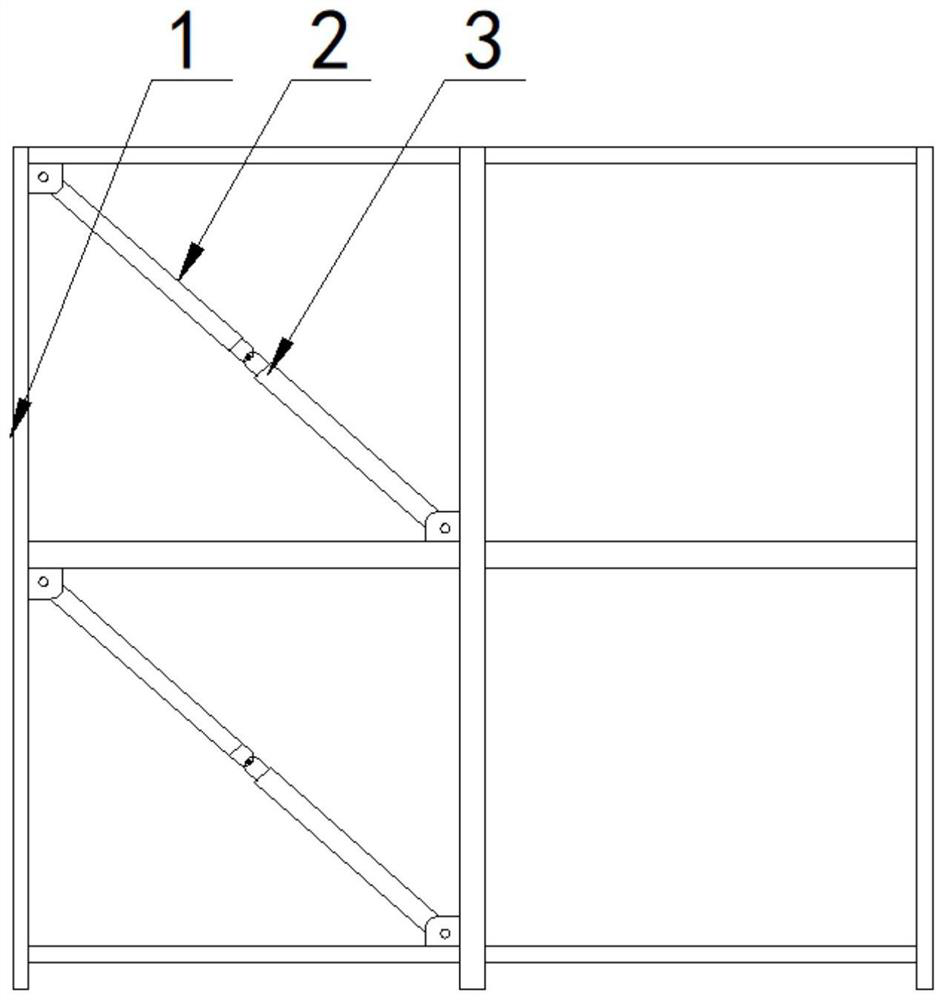

Image

Examples

Embodiment approach 1

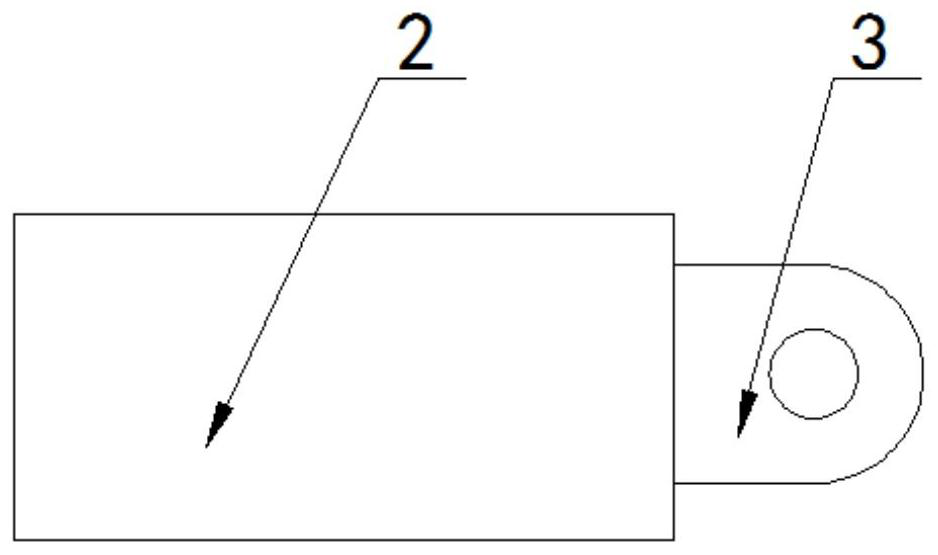

[0040] Please refer to image 3 , the connecting piece 3 is a connecting piece provided with a hinge hole and it is directly affixed to the free end of the support body 2; bars or steel plates with through holes; the low-yield steel bars or steel plates with through holes are respectively symmetrically distributed on both sides of the two hinged connecting pieces.

[0041] In this embodiment, the connecting piece is directly connected to the supporting body, and the connecting piece between the two supporting bodies can be hinged.

[0042] In this embodiment, the energy dissipation parts are low-yield steel bars or steel plates with through holes connected between the ends of the two supports 2; the low-yield steel bars or steel plates with through holes are respectively symmetrically distributed in The two sides of the two connecting pieces that are hinged to each other are as follows: Figure 3a and Figure 3b shown.

Embodiment approach 2

[0044] Please refer to Figure 4, the connector 3 includes: a first connecting steel plate 8 and a connecting piece connected to one side of the first connecting steel plate 8; Connecting steel plate 9; the energy dissipation element is a low-yield steel bar or a steel plate with a through hole connected between the two first connecting steel plates 8 and symmetrically located between the two connecting plates.

[0045] The difference from Embodiment 1 is that in this embodiment, the connecting piece is not directly connected to the support body, but is connected to the second connecting steel plate correspondingly provided on the support body through the first connecting steel plate. This design enhances this embodiment versatility.

[0046] In this embodiment, the energy dissipation member is a low-yield steel bar or a steel plate with a through hole that is connected between the two first connecting steel plates 8 and symmetrically located between the two connecting pieces...

Embodiment approach 3

[0048] Please refer to Figure 5 As shown, the connecting piece 3 is a cross-shaped joint connected to the support body 2, and the middle part of the cross-shaped joint extends with a horizontal connecting part integrally provided with it and has a hinge hole; the energy dissipation element is horizontally connected to two Low-yield steel bars or steel plates with through holes between the corresponding upper and lower ends of the cross joint.

[0049] exist Figure 5 Among them, the two connecting parts are hingedly connected through a horizontal connecting part.

[0050] Figure 5 Among them, the energy dissipation part is a low-yield steel bar or a steel plate with a through hole horizontally connected between the upper and lower ends of the two cross-shaped joints, respectively as Figure 5a and Figure 5b shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com