Ribbed aerated concrete tongue-and-groove floor system and assembly method thereof

A technology of aerated concrete and tongue-and-groove slabs, applied in the direction of floor slabs, building components, buildings, etc., can solve the problems of difficult horizontal tongue-and-groove connection, insufficient bending stiffness, insufficient spanning ability, etc., and achieve reliable and convenient connection and bearing capacity. High, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

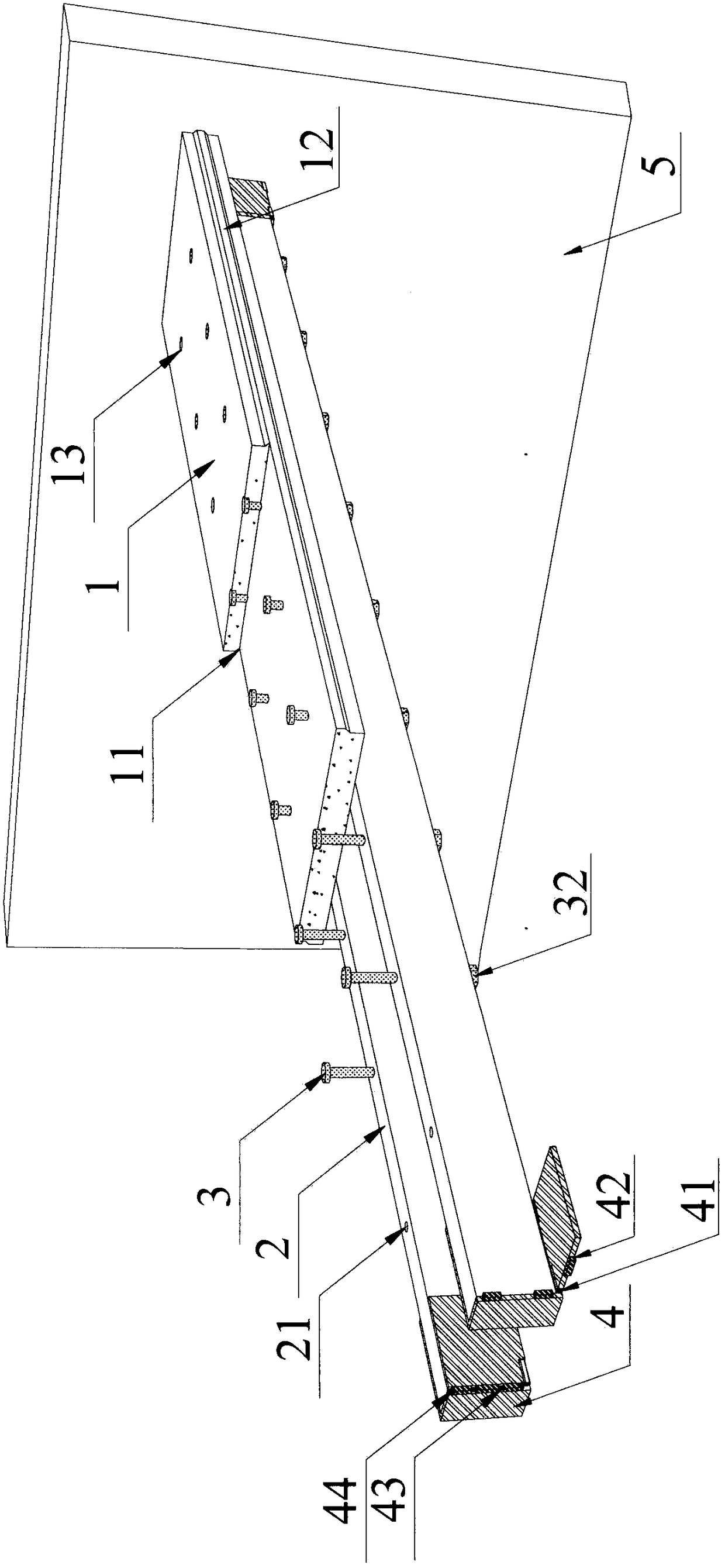

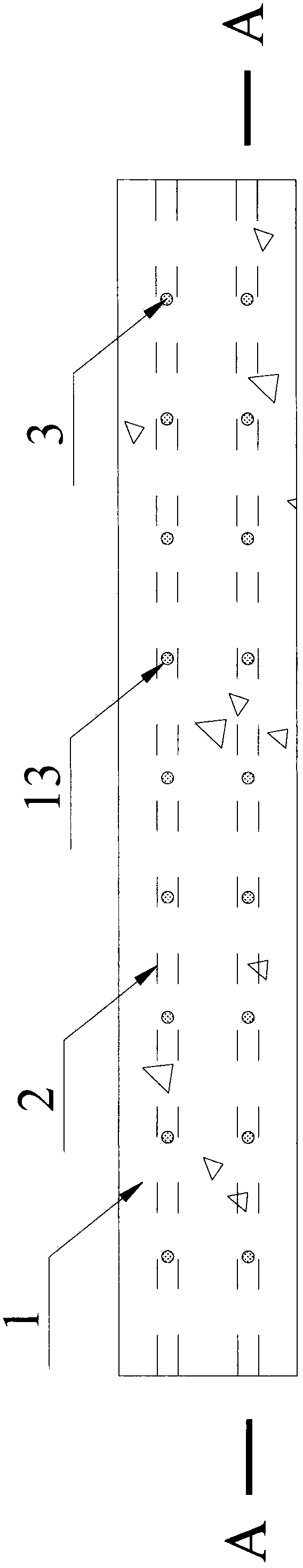

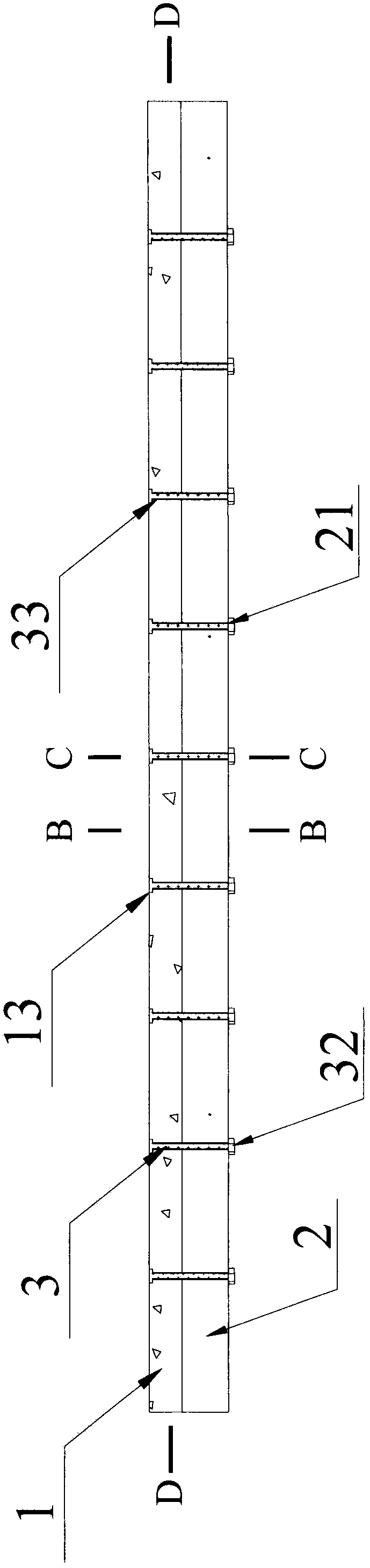

[0042] As shown in the accompanying drawings, the present invention provides a ribbed aerated concrete rebate slab system, which is composed of prefabricated aerated concrete rebate slab 1, longitudinal rib 2, bolt connector 3 and section steel support 4, and is characterized in that the longitudinal rib 2. Arranged at the bottom of the prefabricated aerated concrete tongue and groove slab 1 at intervals. The two are fastened by bolt connectors 3. The periphery of the bolt connector 3 is wrapped with rubber gaskets 33. The longitudinal ribs 2 are provided with steel supports 4 at both ends along the length direction. , the section steel support 4 is fixed on the load-bearing wall 5 to form an assembly system. The prefabricated aer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com