Clutch device

A clutch device and clutch technology, applied in the clutch field, can solve the problems of failure of the separation system, blockage of the oil inlet hole of the performance of the separation system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

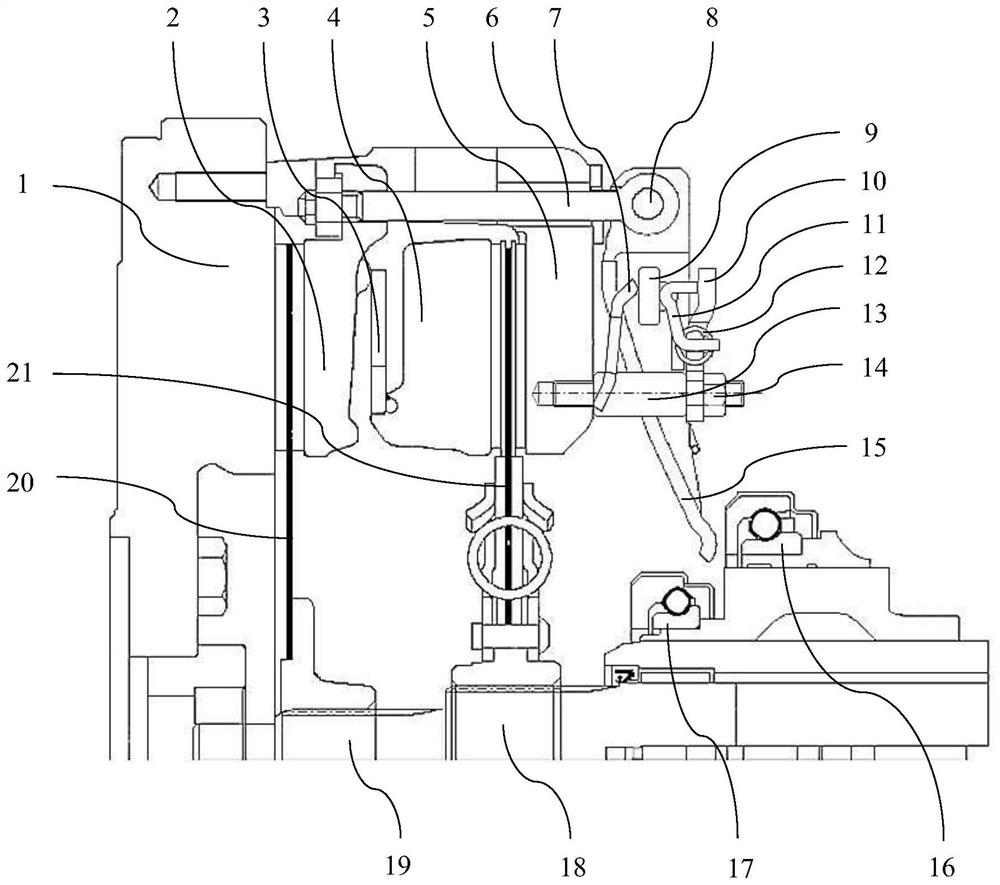

[0026] figure 1 A schematic half-sectional view of a clutch device embodied according to a preferred embodiment is shown. In this embodiment, the clutch device is designed as a dual clutch device for a tractor. The double clutch device includes a clutch housing 5, two friction clutches and actuating mechanisms respectively corresponding to the two friction clutches.

[0027] In the present embodiment, two friction clutches, a first clutch and a second clutch, are used to selectively transmit torque generated by the engine, respectively. The first clutch selectively connects the engine with the drive. A second clutch selectively connects the engine and the auxiliary drive. Here, the first clutch is closer to the engine than the second clutch.

[0028] The first clutch includes a counter pressure plate 1 , a pressure plate 2 and a friction disc 20 arranged between the counter pressure plate 1 and the pressure plate 2 . In this case, the counterplate 1 is connected in a rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com